Основной каталог Kyocera 2016-2017 - страница 513

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

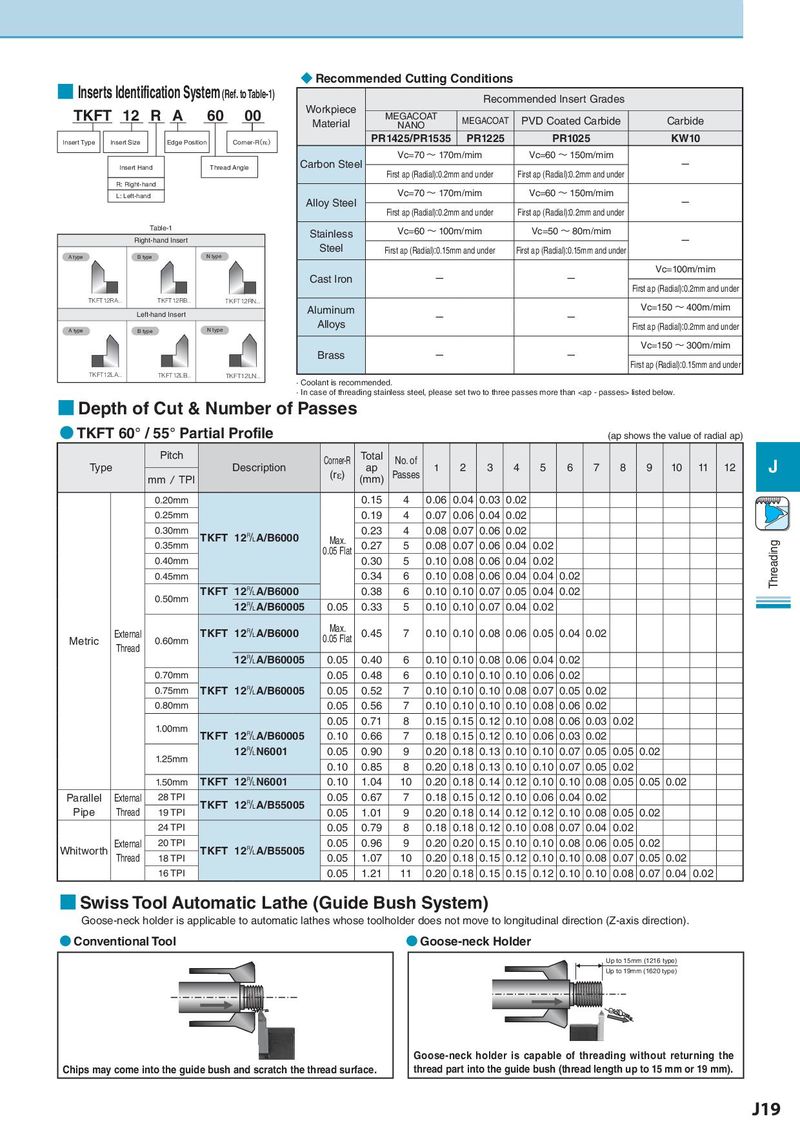

■ Inserts Identification System (Ref. toTable-1) ◆ Recommended Cutting Conditions

Recommended Insert Grades

TKFT 12 R A 60 00 Workpiece MEGACOAT

Material NANO MEGACOAT PVD Coated Carbide Carbide

Insert Type Insert Size Edge Position Corner-R(rH) PR1425/PR1535 PR1225 PR1025 KW10

Vc=70 ~ 170m/mim Vc=60 ~ 150m/mim

Insert Hand Thread Angle Carbon Steel First ap (Radial):0.2mm and under First ap (Radial):0.2mm and under -

R: Right-hand

L: Left-hand Vc=70 ~ 170m/mim Vc=60 ~ 150m/mim

Alloy Steel First ap (Radial):0.2mm and under First ap (Radial):0.2mm and under -

Table-1 Stainless Vc=60 ~ 100m/mim Vc=50 ~ 80m/mim

Right-hand Insert Steel -

A type B type N type First ap (Radial):0.15mm and under First ap (Radial):0.15mm and under

Vc=100m/mim

Cast Iron - - First ap (Radial):0.2mm and under

TKFT12RA.. TKFT12RB.. TKFT12RN.. Vc=150 ~ 400m/mim

Left-hand Insert Aluminum - -

A type B type N type Alloys First ap (Radial):0.2mm and under

Vc=150 ~ 300m/mim

Brass - - First ap (Radial):0.15mm and under

TKFT12LA.. TKFT12LB.. TKFT12LN..

· Coolant is recommended.

· In case of threading stainless steel, please set two to three passes more than