Основной каталог Kyocera 2016-2017 - страница 489

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

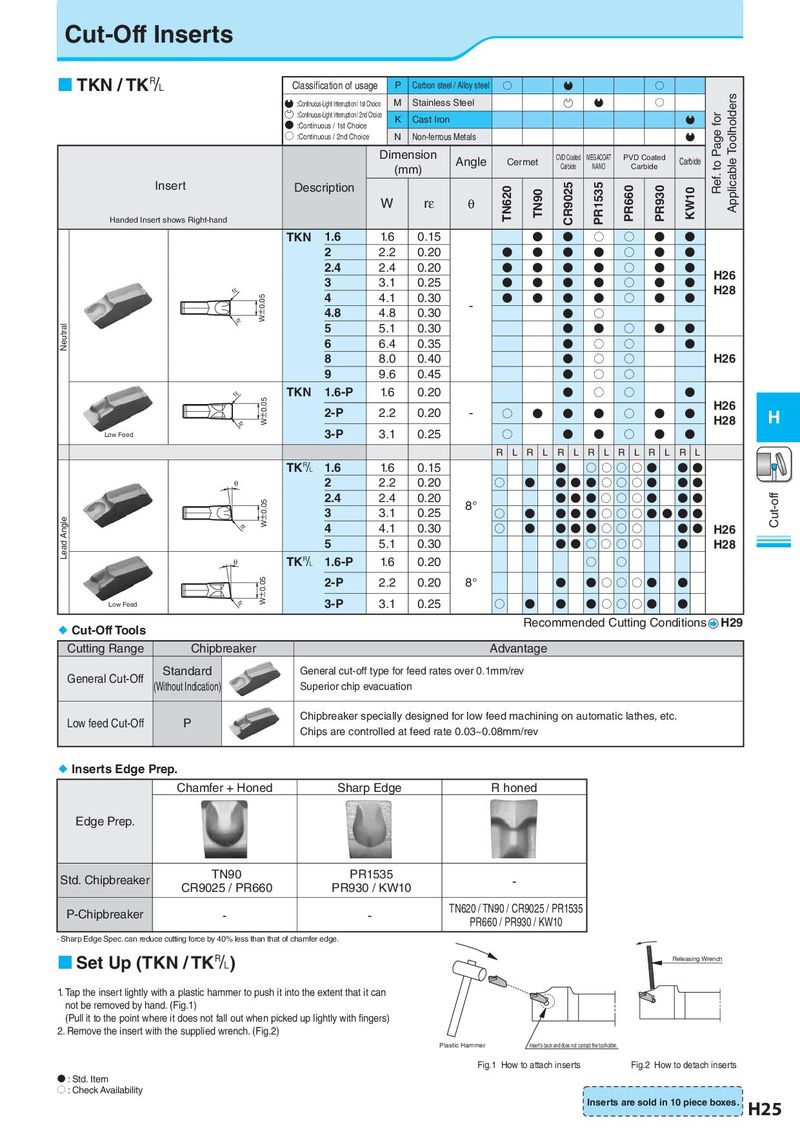

Cut-Off Inserts TKN / TK& Classification of usage P Carbon steel / Alloy steel ○ ○ :Continuous-Light Interruption / 1st Choice M Stainless Steel ○ Applicable Toolholders :Continuous-Light Interruption / 2nd Choice K Cast Iron Ref. to Page for ● :Continuous / 1st Choice ○ :Continuous / 2nd Choice N Non-ferrous Metals Dimension Angle Cermet CVD Coated MEGACOAT PVD Coated Carbide (mm) Carbide NANO Carbide Insert Description TN620 TN90 CR9025 PR1535 PR660 PR930 KW10 W rε θ Handed Insert shows Right-hand TKN 1.6 1.6 0.15 ● ● ○ ○ ● ● 2 2.2 0.20 ● ● ● ● ○ ● ● 2.4 2.4 0.20 ● ● ● ● ○ ● ● H26 rε 3 3.1 0.25 ● ● ● ● ○ ● ● H28 W±0.05 4 4.1 0.30 - ● ● ● ● ○ ● ● 4.8 4.8 0.30 ● ○ Neutral rε 5 5.1 0.30 ● ● ○ ● ● 6 6.4 0.35 ● ○ ○ ● 8 8.0 0.40 ● ○ ○ H26 9 9.6 0.45 ● ○ ○ rε TKN 1.6-P 1.6 0.20 ● ○ ○ ● W±0.05 2-P 2.2 0.20 - ○ ● ● ● ○ ● ● H26 H rε H28 Low Feed 3-P 3.1 0.25 ○ ● ● ○ ● ● R L R L R L R L R L R L R L TK& 1.6 1.6 0.15 ● ○ ○ ○ ○ ● ● ● θ 2 2.2 0.20 ○ ● ● ● ● ○ ○ ○ ● ● ● W±0.05 2.4 2.4 0.20 8° ● ● ● ○ ○ ○ ● ● ● Cut-off Lead Angle 3 3.1 0.25 ○ ● ● ● ● ○ ○ ○ ● ● ● ● rε 4 4.1 0.30 ○ ● ● ● ● ○ ○ ○ ● ● H26 5 5.1 0.30 ● ● ○ ○ ○ ○ ● H28 θ TK& 1.6-P 1.6 0.20 ○ ○ W±0.05 2-P 2.2 0.20 8° ● ●○○○● ● Low Feed rε 3-P 3.1 0.25 ○ ● ● ●○○○● ● Cut-Off Tools Recommended Cutting Conditions H29 Cutting Range Chipbreaker Advantage General Cut-Off Standard General cut-off type for feed rates over 0.1mm/rev (Without Indication) Superior chip evacuation Low feed Cut-Off P Chipbreaker specially designed for low feed machining on automatic lathes, etc. Chips are controlled at feed rate 0.03~0.08mm/rev Inserts Edge Prep. Chamfer + Honed Sharp Edge R honed Edge Prep. Std. Chipbreaker TN90 PR1535 - CR9025 / PR660 PR930 / KW10 P-Chipbreaker - - TN620 / TN90 / CR9025 / PR1535 PR660 / PR930 / KW10 · Sharp Edge Spec. can reduce cutting force by 40% less than that of chamfer edge. Set Up (TKN / TK&) Releasing Wrench 1. Tap the insert lightly with a plastic hammer to push it into the extent that it can not be removed by hand. (Fig.1) (Pull it to the point where it does not fall out when picked up lightly with fingers) 2. Remove the insert with the supplied wrench. (Fig.2) Plastic Hammer Insert’s back end does not contact the toolholder. Fig.1 How to attach inserts Fig.2 How to detach inserts N : Std. Item O : Check Availability Inserts are sold in 10 piece boxes. H25