Основной каталог Kyocera 2016-2017 - страница 485

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

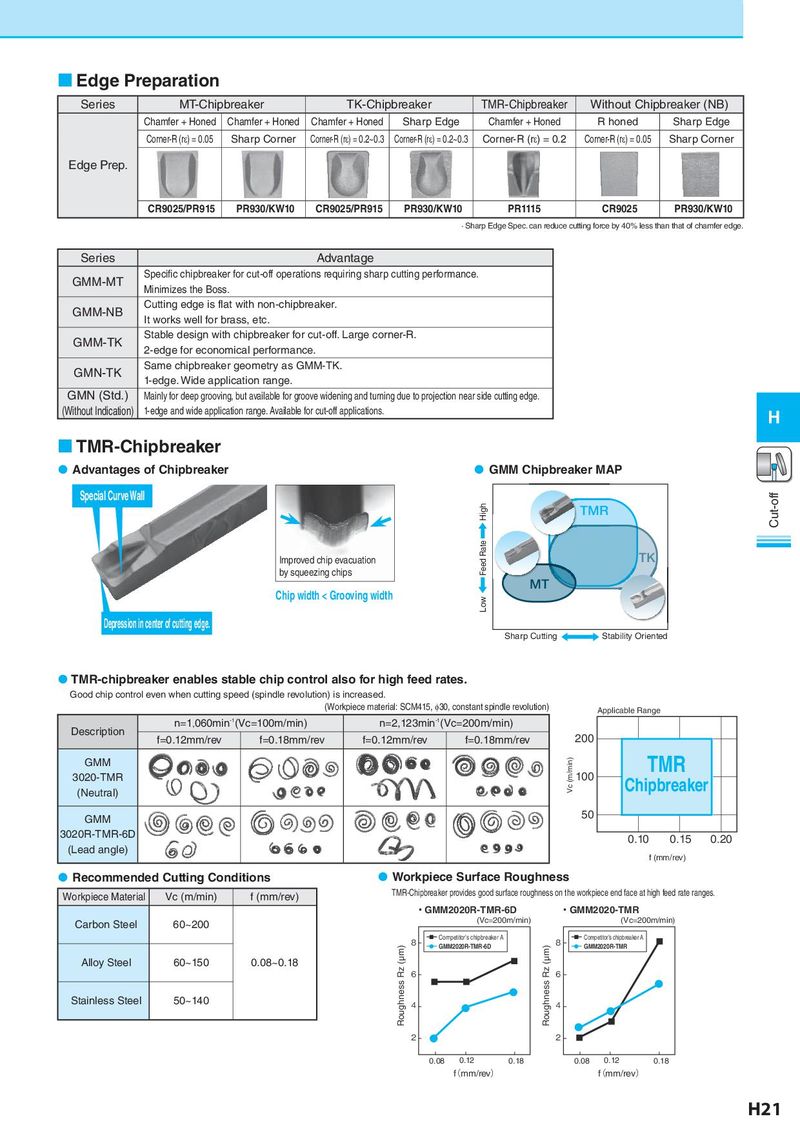

Edge Preparation Series MT-Chipbreaker TK-Chipbreaker TMR-Chipbreaker Without Chipbreaker (NB) Chamfer + Honed Chamfer + Honed Chamfer + Honed Sharp Edge Chamfer + Honed R honed Sharp Edge Corner-R (rε) = 0.05 Sharp Corner Corner-R (rε) = 0.2~0.3 Corner-R (rε) = 0.2~0.3 Corner-R (rε) = 0.2 Corner-R (rε) = 0.05 Sharp Corner Edge Prep. CR9025/PR915 PR930/KW10 CR9025/PR915 PR930/KW10 PR1115 CR9025 PR930/KW10 · Sharp Edge Spec. can reduce cutting force by 40% less than that of chamfer edge. Series Advantage GMM-MT Specific chipbreaker for cut-off operations requiring sharp cutting performance. Minimizes the Boss. GMM-NB Cutting edge is flat with non-chipbreaker. It works well for brass, etc. GMM-TK Stable design with chipbreaker for cut-off. Large corner-R. 2-edge for economical performance. GMN-TK Same chipbreaker geometry as GMM-TK. 1-edge. Wide application range. GMN (Std.) Mainly for deep grooving, but available for groove widening and turning due to projection near side cutting edge. (Without Indication) 1-edge and wide application range. Available for cut-off applications. H TMR-Chipbreaker Advantages of Chipbreaker GMM Chipbreaker MAP Special Curve Wall Cut-off High TMR Improved chip evacuation Feed Rate TK by squeezing chips Chip width < Grooving width MT Low Depression in center of cutting edge. Sharp Cutting Stability Oriented TMR-chipbreaker enables stable chip control also for high feed rates. Good chip control even when cutting speed (spindle revolution) is increased. (Workpiece material: SCM415, φ30, constant spindle revolution) Applicable Range Description n=1,060min-1(Vc=100m/min) n=2,123min-1(Vc=200m/min) f=0.12mm/rev f=0.18mm/rev f=0.12mm/rev f=0.18mm/rev 200 GMM Vc (m/min) TMR 3020-TMR 100 Chipbreaker (Neutral) GMM 50 3020R-TMR-6D 0.10 0.15 0.20 (Lead angle) f (mm/rev) Recommended Cutting Conditions Workpiece Surface Roughness Workpiece Material Vc (m/min) f (mm/rev) TMR-Chipbreaker provides good surface roughness on the workpiece end face at high feed rate ranges. ・GMM2020R-TMR-6D ・GMM2020-TMR Carbon Steel 60~200 (Vc=200m/min) (Vc=200m/min) 8 Competitor’s chipbreaker A 8 Competitor’s chipbreaker A Roughness Rz (μm) GMM2020R-TMR-6D Roughness Rz (μm) GMM2020R-TMR Alloy Steel 60~150 0.08~0.18 6 6 Stainless Steel 50~140 4 4 2 2 0.08 0.12 0.18 0.08 0.12 0.18 (f mm/rev) (f mm/rev) H21