Основной каталог Kyocera 2016-2017 - страница 475

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

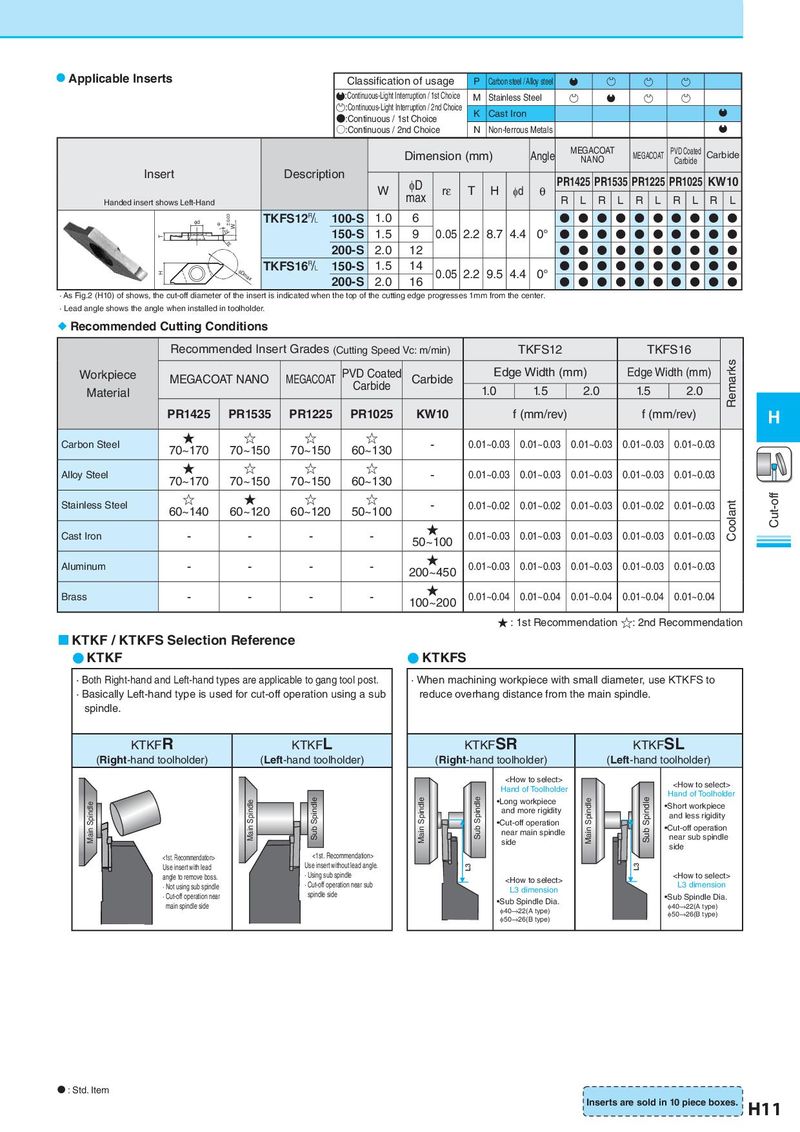

Applicable Inserts Classification of usage P Carbon steel / Alloy steel

:Continuous-Light Interruption / 1st Choice M Stainless Steel

:Continuous-Light Interruption / 2nd Choice K Cast Iron

●:Continuous / 1st Choice

○:Continuous / 2nd Choice N Non-ferrous Metals

Dimension (mm) Angle MEGACOAT MEGACOAT PVD Coated Carbide

NANO Carbide

Insert Description φD PR1425 PR1535 PR1225 PR1025 KW10

W max rε T H φd θ R L R L R L R L R L

Handed insert shows Left-Hand

φd θ ±0.03 W TKFS12& 100-S 1.0 6 ● ● ● ● ● ● ● ● ● ●

rε 150-S 1.5 9 0.05 2.2 8.7 4.4 0° ● ● ● ● ● ● ● ● ● ●

T

rε 200-S 2.0 12 ● ● ● ● ● ● ● ● ● ●

H φDmax TKFS16& 150-S 1.5 14 0.05 2.2 9.5 4.4 0° ● ● ● ● ● ● ● ● ● ●

200-S 2.0 16 ● ● ● ● ● ● ● ● ● ●

· As Fig.2 (H10) of shows, the cut-off diameter of the insert is indicated when the top of the cutting edge progresses 1mm from the center.

· Lead angle shows the angle when installed in toolholder.

Recommended Cutting Conditions

Recommended Insert Grades (Cutting Speed Vc: m/min) TKFS12 TKFS16

Workpiece MEGACOAT NANO MEGACOAT PVD Coated Carbide Edge Width (mm) Edge Width (mm) Remarks

Material Carbide 1.0 1.5 2.0 1.5 2.0

PR1425 PR1535 PR1225 PR1025 KW10 f (mm/rev) f (mm/rev) H

Carbon Steel ★ ☆ ☆ ☆ - 0.01~0.03 0.01~0.03 0.01~0.03 0.01~0.03 0.01~0.03

70~170 70~150 70~150 60~130

Alloy Steel ★ ☆ ☆ ☆ - 0.01~0.03 0.01~0.03 0.01~0.03 0.01~0.03 0.01~0.03

70~170 70~150 70~150 60~130

Stainless Steel ☆ ★ ☆ ☆ - 0.01~0.02 0.01~0.02 0.01~0.03 0.01~0.02 0.01~0.03 Coolant Cut-off

60~140 60~120 60~120 50~100

Cast Iron - - - - ★ 0.01~0.03 0.01~0.03 0.01~0.03 0.01~0.03 0.01~0.03

50~100

Aluminum - - - - ★ 0.01~0.03 0.01~0.03 0.01~0.03 0.01~0.03 0.01~0.03

200~450

Brass - - - - ★ 0.01~0.04 0.01~0.04 0.01~0.04 0.01~0.04 0.01~0.04

100~200

★ : 1st Recommendation ☆: 2nd Recommendation

KTKF / KTKFS Selection Reference

● KTKF ● KTKFS

· Both Right-hand and Left-hand types are applicable to gang tool post. · When machining workpiece with small diameter, use KTKFS to

· Basically Left-hand type is used for cut-off operation using a sub reduce overhang distance from the main spindle.

spindle.

KTKFR KTKFL KTKFSR KTKFSL

(Right-hand toolholder) (Left-hand toolholder) (Right-hand toolholder) (Left-hand toolholder)