Основной каталог Kyocera 2016-2017 - страница 403

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

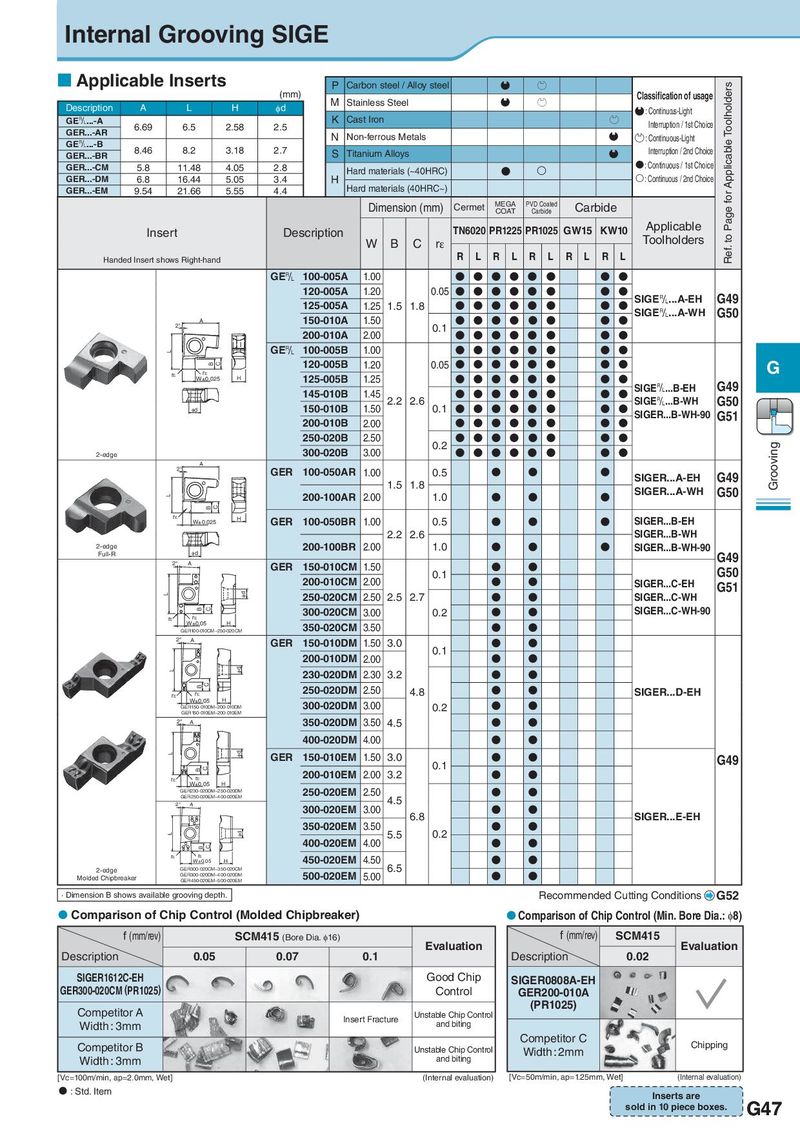

Internal Grooving SIGE Applicable Inserts P Carbon steel / Alloy steel Q P Ref. to Page for Applicable Toolholders (mm) M Stainless Steel Q P Classification of usage Description A L H φd :Continuous-Light GE&...-A 6.69 6.5 2.58 2.5 K Cast Iron P Interruption / 1st Choice GER...-AR N Non-ferrous Metals Q :Continuous-Light GE&...-B 8.46 8.2 3.18 2.7 Interruption / 2nd Choice GER...-BR S Titanium Alloys Q GER...-CM 5.8 11.48 4.05 2.8 Hard materials (~40HRC) N : Continuous / 1st Choice GER...-DM 6.8 16.44 5.05 3.4 H : Continuous / 2nd Choice GER...-EM 9.54 21.66 5.55 4.4 Hard materials (40HRC~) Dimension (mm) Cermet MEGA PVD Coated Carbide COAT Carbide Insert Description TN6020 PR1225 PR1025 GW15 KW10 Applicable W B C rε Toolholders Handed Insert shows Right-hand R L R L R L R L R L GE& 100-005A 1.00 N N N N N N N N 120-005A 1.20 0.05 N N N N N N N N SIGE&...A-EH G49 125-005A 1.25 1.5 1.8 N N N N N N N N SIGE&...A-WH G50 A 150-010A 1.50 N N N N N N N N 2° 0.1 200-010A 2.00 N N N N N N N N L GE& 100-005B 1.00 N N N N N N N N B C 120-005B 1.20 0.05 N N N N N N N N G rε rε H 125-005B 1.25 N N N N N N N N W±0.025 G49 145-010B 1.45 N N N N N N N N SIGE&...B-EH 150-010B 1.50 2.2 2.6 0.1 N N N N N N N N SIGE&...B-WH G50 φd SIGER...B-WH-90 G51 200-010B 2.00 N N N N N N N N 250-020B 2.50 0.2 N N N N N N N N Grooving 2-edge 300-020B 3.00 N N N N N N N N 2° A GER 100-050AR 1.00 0.5 N N N SIGER...A-EH G49 1.5 1.8 SIGER...A-WH G50 L 200-100AR 2.00 1.0 N N N B C rε W±0.025 H GER 100-050BR 1.00 0.5 N N N SIGER...B-EH 2.2 2.6 SIGER...B-WH 2-edge 200-100BR 2.00 1.0 N N N SIGER...B-WH-90 Full-R φd G49 2° A GER 150-010CM 1.50 N N 200-010CM 2.00 0.1 N N G50 SIGER...C-EH G51 L φd 250-020CM 2.50 2.5 2.7 N N SIGER...C-WH B C 300-020CM 3.00 0.2 N N SIGER...C-WH-90 rε rε W±0.05 H 350-020CM 3.50 N N GER100-010CM~250-020CM 2° A GER 150-010DM 1.50 3.0 N N 200-010DM 2.00 0.1 N N L φd 230-020DM 2.30 3.2 N N B C 250-020DM 2.50 N N rε rε 4.8 SIGER...D-EH W±0.05 H 300-020DM 3.00 N N GER150-010DM~200-010DM 0.2 GER150-010EM~200-010EM 2° A 350-020DM 3.50 4.5 N N 400-020DM 4.00 N N L φd GER 150-010EM 1.50 3.0 N N G49 B C 0.1 rε rε 200-010EM 2.00 3.2 N N W±0.05 H GER230-020DM~250-020DM 250-020EM 2.50 N N GER250-020EM~400-020EM 4.5 2° A 300-020EM 3.00 N N 6.8 SIGER...E-EH φd 350-020EM 3.50 5.5 0.2 N N L B C 400-020EM 4.00 N N rε rε 450-020EM 4.50 N N W±0.05 H 2-edge GER300-020CM~350-020CM 6.5 Molded Chipbreaker GER300-020DM~400-020DM 500-020EM 5.00 N N GER450-020EM~500-020EM · Dimension B shows available grooving depth. Recommended Cutting Conditions G52 Comparison of Chip Control (Molded Chipbreaker) Comparison of Chip Control (Min. Bore Dia.: φ8) f (mm/rev) SCM415 (Bore Dia. φ16) f (mm/rev) SCM415 Evaluation 0.02 Evaluation Description 0.05 0.07 0.1 Description SIGER1612C-EH Good Chip SIGER0808A-EH GER300-020CM (PR1025) Control GER200-010A Competitor A (PR1025) Insert Fracture Unstable Chip Control Width : 3mm and biting Competitor B Competitor C Chipping Unstable Chip Control Width : 2mm Width : 3mm and biting [Vc=100m/min, ap=2.0mm, Wet] (Internal evaluation) [Vc=50m/min, ap=1.25mm, Wet] (Internal evaluation) : Std. Item Inserts are sold in 10 piece boxes. G47