Основной каталог Kyocera 2016-2017 - страница 388

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

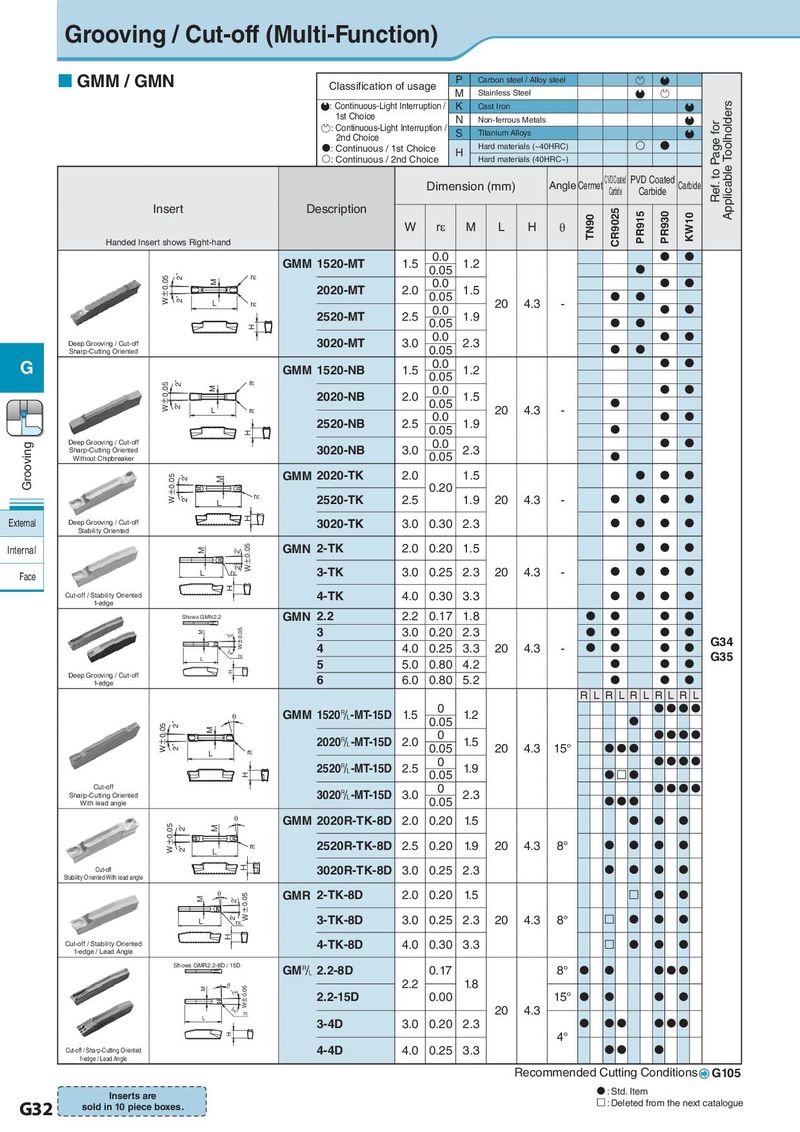

Grooving / Cut-off (Multi-Function) GMM / GMN Classification of usage P Carbon steel / Alloy steel M Stainless Steel : Continuous-Light Interruption / K Cast Iron Applicable Toolholders 1st Choice N Non-ferrous Metals Ref. to Page for : Continuous-Light Interruption / S Titanium Alloys 2nd Choice : Continuous / 1st Choice H Hard materials (~40HRC) : Continuous / 2nd Choice Hard materials (40HRC~) Dimension (mm) Angle Cermet CVD Coated PVD Coated Carbide Carbide Carbide Insert Description TN90 CR9025 PR915 PR930 KW10 W rε M L H θ Handed Insert shows Right-hand GMM 1520-MT 1.5 0.0 1.2 W±0.05 2゜ rH 0.05 M 0.0 2゜ 2020-MT 2.0 0.05 1.5 L rH 0.0 20 4.3 - 2520-MT 2.5 0.05 1.9 H Deep Grooving / Cut-off 3020-MT 3.0 0.0 2.3 Sharp-Cutting Oriented 0.05 G GMM 1520-NB 1.5 0.0 1.2 W±0.05 2゜ rH 0.05 M 0.0 2゜ 2020-NB 2.0 0.05 1.5 L rH 0.0 20 4.3 - 2520-NB 2.5 0.05 1.9 H Grooving Deep Grooving / Cut-off 3020-NB 3.0 0.0 2.3 Sharp-Cutting Oriented 0.05 Without Chipbreaker W±0.05 2゜ M GMM 2020-TK 2.0 1.5 2゜ rH 0.20 L 2520-TK 2.5 1.9 20 4.3 - External Deep Grooving / Cut-off H 3020-TK 3.0 0.30 2.3 Stability Oriented Internal M 2° 2° W±0.05 GMN 2-TK 2.0 0.20 1.5 Face L rH 3-TK 3.0 0.25 2.3 20 4.3 - H Cut-off / Stability Oriented 4-TK 4.0 0.30 3.3 1-edge Shows GMN2.2 GMN 2.2 2.2 0.17 1.8 M 2゜ W±0.05 3 3.0 0.20 2.3 2゜ 4 4.0 0.25 3.3 20 4.3 - G34 L rH G35 H 5 5.0 0.80 4.2 Deep Grooving / Cut-off 6 6.0 0.80 5.2 1-edge RL RL RL RLRL T GMM 1520&-MT-15D 1.5 0 1.2 W±0.05 2゜ M 0.05 2゜ 2020&-MT-15D 2.0 0 1.5 L rH 0.05 20 4.3 15° 2520&-MT-15D 2.5 0 1.9 H 0.05 Cut-off 3020&-MT-15D 3.0 0 2.3 Sharp-Cutting Oriented 0.05 With lead angle 2゜ M T GMM 2020R-TK-8D 2.0 0.20 1.5 W±0.05 2゜ L rH 2520R-TK-8D 2.5 0.20 1.9 20 4.3 8° Cut-off H 3020R-TK-8D 3.0 0.25 2.3 Stability Oriented With lead angle M T 2° 2° W±0.05 GMR 2-TK-8D 2.0 0.20 1.5 L rH 3-TK-8D 3.0 0.25 2.3 20 4.3 8° H Cut-off / Stability Oriented 4-TK-8D 4.0 0.30 3.3 1-edge / Lead Angle Shows GMR2.2-8D / 15D GM& 2.2-8D 0.17 8° M T 2゜ W±0.05 2.2 1.8 2.2-15D 0.00 15° 2゜ rH 20 4.3 L 3-4D 3.0 0.20 2.3 H 4° Cut-off / Sharp-Cutting Oriented 4-4D 4.0 0.25 3.3 1-edge / Lead Angle Recommended Cutting Conditions G105 Inserts are : Std. Item G32 sold in 10 piece boxes. : Deleted from the next catalogue