Основной каталог Kyocera 2016-2017 - страница 176

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

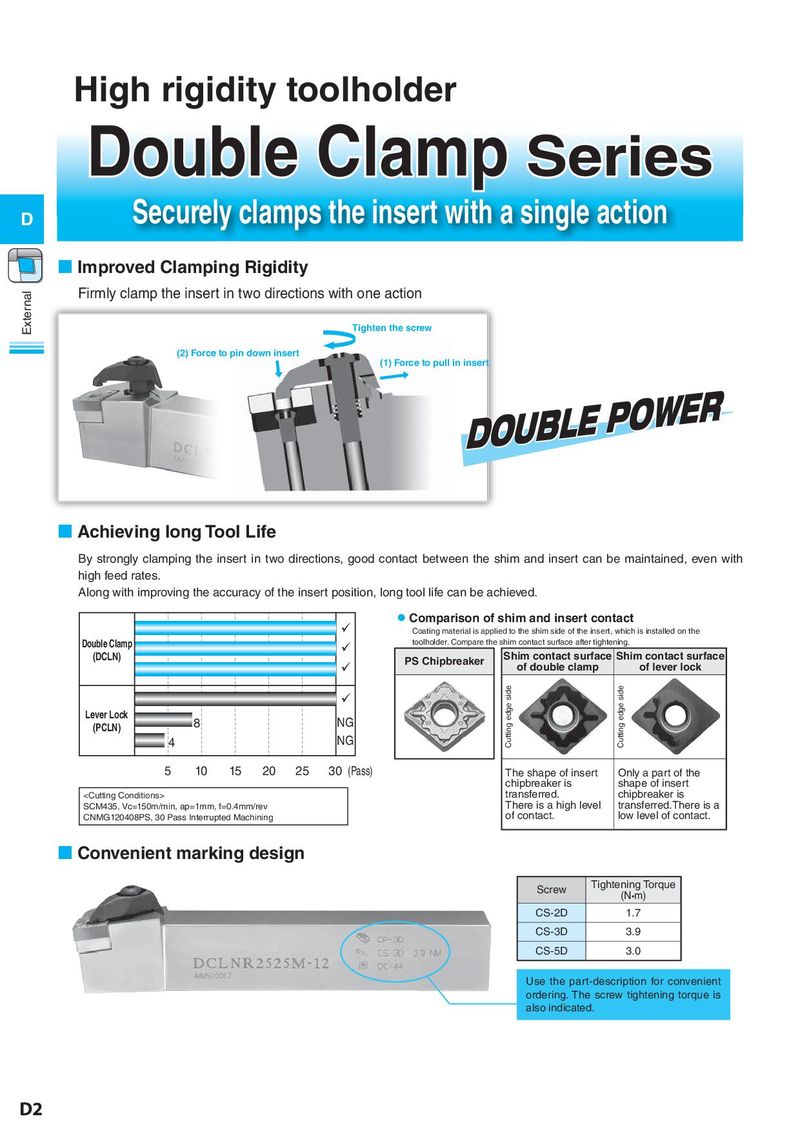

High rigidity toolholder

Double Clamp Series

D Securely clamps the insert with a single action

¢ Improved Clamping Rigidity

External Firmly clamp the insert in two directions with one action

Tighten the screw

(2) Force to pin down insert

(1) Force to pull in insert

DOUBLE POWER

¢ Achieving long Tool Life

By strongly clamping the insert in two directions, good contact between the shim and insert can be maintained, even with

high feed rates.

Along with improving the accuracy of the insert position, long tool life can be achieved.

l Comparison of shim and insert contact

Coating material is applied to the shim side of the insert, which is installed on the

Double Clamp toolholder. Compare the shim contact surface after tightening.

(DCLN) PS Chipbreaker Shim contact surface Shim contact surface

of double clamp of lever lock

Cutting edge side Cutting edge side

Lever Lock 8 NG

(PCLN)

4 NG

5 10 15 20 25 30 (Pass) The shape of insert Only a part of the

chipbreaker is shape of insert