Основной каталог Kyocera 2016-2017 - страница 147

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

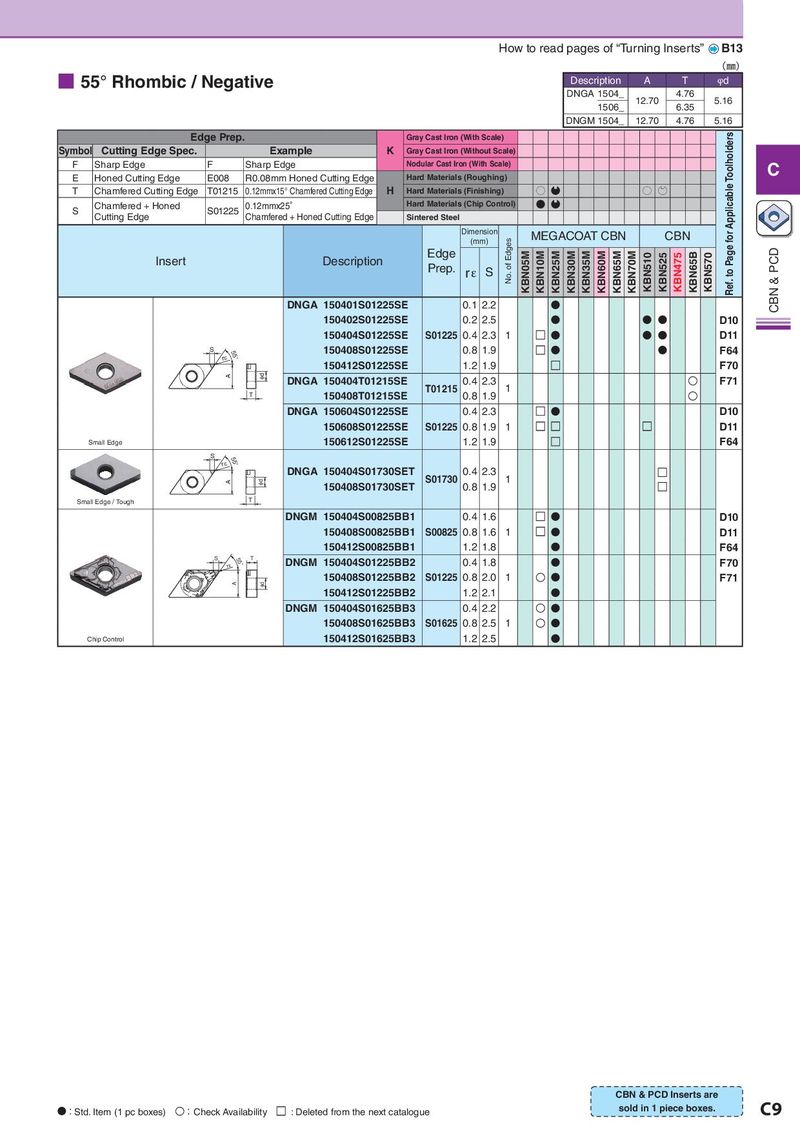

How to read pages of “Turning Inserts” B13 (㎜) ■ 55° Rhombic / Negative Description A T φd DNGA 1504_ 12.70 4.76 5.16 1506_ 6.35 DNGM 1504_ 12.70 4.76 5.16 Edge Prep. Gray Cast Iron (With Scale) Ref. to Page for Applicable Toolholders Symbol Cutting Edge Spec. Example K Gray Cast Iron (Without Scale) F Sharp Edge F Sharp Edge Nodular Cast Iron (With Scale) C E Honed Cutting Edge E008 R0.08mm Honed Cutting Edge Hard Materials (Roughing) T Chamfered Cutting Edge T01215 0.12mmx15° Chamfered Cutting Edge H Hard Materials (Finishing) O Q O P S Chamfered + Honed S01225 0.12mmx25° Hard Materials (Chip Control) N Q Cutting Edge Chamfered + Honed Cutting Edge Sintered Steel Dimension MEGACOAT CBN CBN (mm) No. of Edges Insert Description Edge KBN05M KBN10M KBN25M KBN30M KBN35M KBN60M KBN65M KBN70M KBN510 KBN525 KBN475 KBN65B KBN570 CBN & PCD Prep. rε S DNGA 150401S01225SE 0.1 2.2 N 150402S01225SE 0.2 2.5 N N N D10 150404S01225SE S01225 0.4 2.3 1 U N N N D11 S 55° 150408S01225SE 0.8 1.9 U N N F64 rH 150412S01225SE 1.2 1.9 F70 U A Id DNGA 150404T01215SE 0.4 2.3 O F71 T 150408T01215SE T01215 0.8 1.9 1 O DNGA 150604S01225SE 0.4 2.3 U N D10 150608S01225SE S01225 0.8 1.9 1 U U U D11 Small Edge 150612S01225SE 1.2 1.9 U F64 S 55° rH DNGA 150404S01730SET 0.4 2.3 S01730 1 U A Id 150408S01730SET 0.8 1.9 U Small Edge / Tough T DNGM 150404S00825BB1 0.4 1.6 U N D10 150408S00825BB1 S00825 0.8 1.6 1 U N D11 150412S00825BB1 1.2 1.8 N F64 S 55° T DNGM 150404S01225BB2 0.4 1.8 N F70 rH A Id 150408S01225BB2 S01225 0.8 2.0 1 O N F71 150412S01225BB2 1.2 2.1 N DNGM 150404S01625BB3 0.4 2.2 O N 150408S01625BB3 S01625 0.8 2.5 1 O N Chip Control 150412S01625BB3 1.2 2.5 N CBN & PCD Inserts are N:Std. Item (1 pc boxes) O:Check Availability U : Deleted from the next catalogue sold in 1 piece boxes. C9