Общий каталог Kemmler 2017 - 2018 - страница 583

Навигация

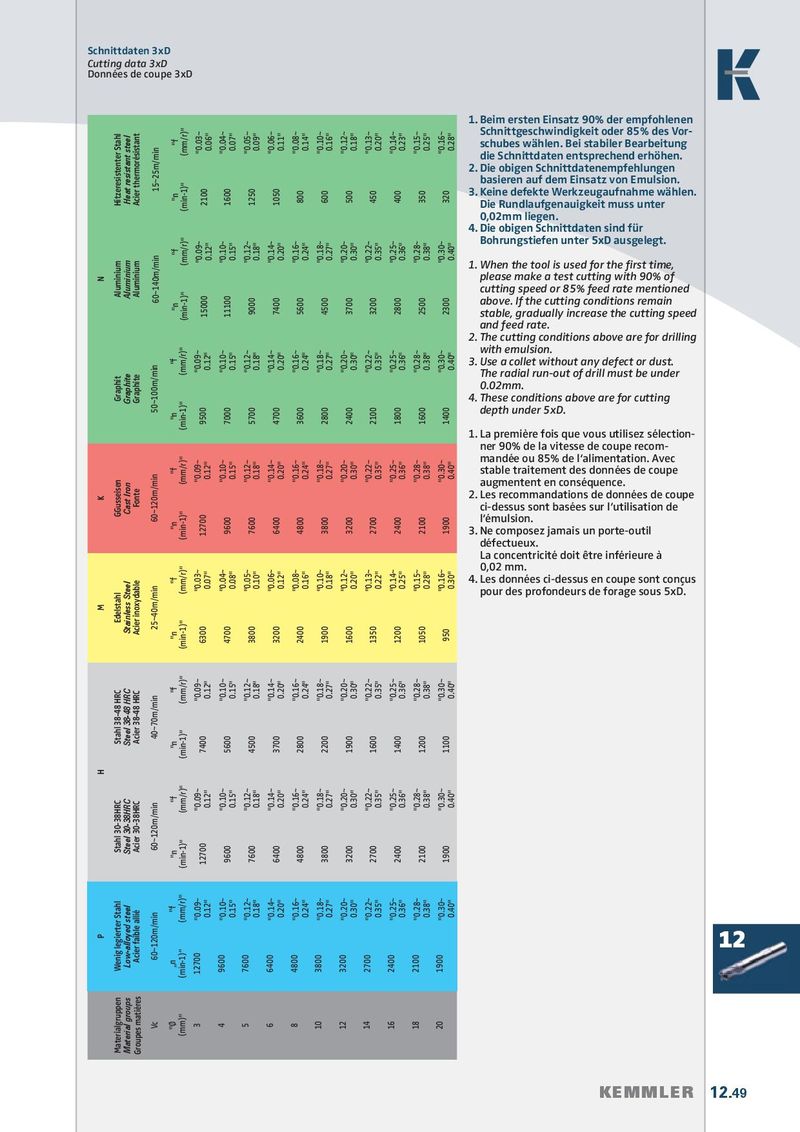

Schnittdaten 3xD Cutting data 3xD Données de coupe 3xD 1. Beim ersten Einsatz 90% der empfohlenen Schnittgeschwindigkeit oder 85% des Vor- "f schubes wählen. Bei stabiler Bearbeitung (mm/r)" "0.03~ 0.06" "0.04~ 0.07" "0.05~ 0.09" "0.06~ 0.11" "0.08~ 0.14" "0.10~ 0.16" "0.12~ 0.18" "0.13~ 0.20" "0.14~ 0.23" "0.15~ 0.25" "0.16~ 0.28" die Schnittdaten entsprechend erhöhen. 2. Die obigen Schnittdatenempfehlungen basieren auf dem Einsatz von Emulsion. 15~25m/min 3. Keine defekte Werkzeugaufnahme wählen. "n Hitzeresistenter Stahl Heat resistant steel Acier thermorésistant 2100 1600 1250 1050 800 600 500 450 400 350 320 (min-1)" Die Rundlaufgenauigkeit muss unter 0,02mm liegen. 4. Die obigen Schnittdaten sind für Bohrungstiefen unter 5xD ausgelegt. "f (mm/r)" "0.09~ 0.12" "0.10~ 0.15" "0.12~ 0.18" "0.14~ 0.20" "0.16~ 0.24" "0.18~ 0.27" "0.20~ 0.30" "0.22~ 0.35" "0.25~ 0.36" "0.28~ 0.38" "0.30~ 0.40" 1. When the tool is used for the first time, N please make a test cutting with 90% of cutting speed or 85% feed rate mentioned Aluminium Aluminium Aluminium 60~140m/min above. If the cutting conditions remain "n 4500 3700 3200 2800 2500 2300 stable, gradually increase the cutting speed (min-1)" 15000 11100 9000 7400 5600 and feed rate. 2. The cutting conditions above are for drilling with emulsion. "f 3. Use a collet without any defect or dust. (mm/r)" "0.09~ 0.12" "0.10~ 0.15" "0.12~ 0.18" "0.14~ 0.20" "0.16~ 0.24" "0.18~ 0.27" "0.20~ 0.30" "0.22~ 0.35" "0.25~ 0.36" "0.28~ 0.38" "0.30~ 0.40" The radial run-out of drill must be under 0.02mm. Graphit Graphite Graphite 4. These conditions above are for cutting 50~100m/min depth under 5xD. "n 9500 7000 5700 4700 3600 2800 2400 2100 1800 1600 1400 (min-1)" 1. La première fois que vous utilisez sélection- ner 90% de la vitesse de coupe recom- mandée ou 85% de l‘alimentation. Avec "f stable traitement des données de coupe (mm/r)" "0.09~ 0.12" "0.10~ 0.15" "0.12~ 0.18" "0.14~ 0.20" "0.16~ 0.24" "0.18~ 0.27" "0.20~ 0.30" "0.22~ 0.35" "0.25~ 0.36" "0.28~ 0.38" "0.30~ 0.40" augmentent en conséquence. 2. Les recommandations de données de coupe Fonte ci-dessus sont basées sur l‘utilisation de GGusseisen Cast Iron 60~120m/min l‘émulsion. "n 9600 7600 6400 4800 3800 3200 2700 2400 2100 1900 3. Ne composez jamais un porte-outil (min-1)" 12700 défectueux. La concentricité doit être inférieure à 0,02 mm. "f 4. Les données ci-dessus en coupe sont conçus (mm/r)" "0.03~ 0.07" "0.04~ 0.08" "0.05~ 0.10" "0.06~ 0.12" "0.08~ 0.16" "0.10~ 0.18" "0.12~ 0.20" "0.13~ 0.22" "0.14~ 0.25" "0.15~ 0.28" "0.16~ 0.30" pour des profondeurs de forage sous 5xD. Edelstahl 25~40m/min Stainless Steel Acier inoxydable "n 6300 4700 3800 3200 2400 1900 1600 1350 1200 1050 950 (min-1)" "f (mm/r)" "0.09~ 0.12" "0.10~ 0.15" "0.12~ 0.18" "0.14~ 0.20" "0.16~ 0.24" "0.18~ 0.27" "0.20~ 0.30" "0.22~ 0.35" "0.25~ 0.36" "0.28~ 0.38" "0.30~ 0.40" 40~70m/min Stahl 38-48 HRC Steel 38-48 HRC Acier 38-48 HRC "n 7400 5600 4500 3700 2800 2200 1900 1600 1400 1200 1100 (min-1)" "f (mm/r)" "0.09~ 0.12" "0.10~ 0.15" "0.12~ 0.18" "0.14~ 0.20" "0.16~ 0.24" "0.18~ 0.27" "0.20~ 0.30" "0.22~ 0.35" "0.25~ 0.36" "0.28~ 0.38" "0.30~ 0.40" Stahl 30-38HRC Steel 30-38HRC Acier 30-38HRC 60~120m/min "n 9600 7600 6400 4800 3800 3200 2700 2400 2100 1900 (min-1)" 12700 "f (mm/r)" "0.09~ 0.12" "0.10~ 0.15" "0.12~ 0.18" "0.14~ 0.20" "0.16~ 0.24" "0.18~ 0.27" "0.20~ 0.30" "0.22~ 0.35" "0.25~ 0.36" "0.28~ 0.38" "0.30~ 0.40" P H M K 12 12 Acier faible allié 60~120m/min Wenig legierter Stahl Low-alloyed steel „n 9600 7600 6400 4800 3800 3200 2700 2400 2100 1900 (min-1)“ 12700 Vc "Ø 3 4 5 6 8 10 12 14 16 18 20 (mm)" Materialgruppen Material groups Groupes matières KEMMLER 12.49

Каталог Kemmler цанговые зажимы

Каталог Kemmler цанговые зажимы Каталог Kemmler зажимные болты

Каталог Kemmler зажимные болты Каталог Kemmler цанговые патроны KPS

Каталог Kemmler цанговые патроны KPS Каталог Kemmler усадочные патроны и усадочная техника

Каталог Kemmler усадочные патроны и усадочная техника Каталог Kemmler сверлильные патроны для станков с ЧПУ

Каталог Kemmler сверлильные патроны для станков с ЧПУ