Основной каталог Karnasch 2021 - страница 1340

Навигация

1 Safety information on how to use cutting tools 1. Basic information Karnasch packages are labeled with general safety information. The tools are not labelled with detailed warning instructions. We suggest to read our safety infor- mation and instructions before handling cutting tools.Furthermore, as a part of your workers safety briefing, please notify the contents of the safety information to all your workers.2 2. Suggestions how to use cutting tools Hazard Counteraction • Solid carbide tools have sharp edges. Handling them with bare hand may • Wear protective gloves when handling tools. cause injuries. • Cutting tools and workpieces can become extremely hot during machin- • Wear protective gloves.ing. Touching them with bare hand may cause burns. 3 • Hot chips produced during the cutting process may cause burns and • Make sure, that the guard doors are closed on the machine and protec- injuries. tion goggles are used. During machine cleaning ensure the machine is stopped and wear protection gloves. • Hot chips, sparks and heat generation during the cutting process • Avoid using cutting tools in environments where there is a possibility of (e.g. by tool breakage) provides a risk of igniting a fire. igniting fire. 4 If it is not possible to use a cooling lubricant, make sure to have a fire prevention countermeasure. • The use of cutting tools with inappropriate cutting conditions or inappro- • Make sure, that the guard doors are closed on the machine and protec- priate cutting tools may cause the tool to break and providing risk of inju- tion goggles are used. Use cutting tools under recommended cutting ries. conditions. • Impact load and rapid increase of cutting forces to excessive wear may • Make sure, that the guard doors are closed on the machine and protec-cause the tool to break. This provides a risk of injuries.tion goggles are used. Change tools before excessive wear occurs.5 • Microtools have an extremely small diameter with a very sharp point • Handle Microtools always with care and wear always suitable gloves. which may puncture the skin if not handled carefully. • During High speed cutting spare parts and chips may be expelled due to • Make sure, that the guard doors are closed on the machine and protec- centrifugal forces. This may cause injuries. tion goggles and protective clothes are worn. 6 • Poor balanced spindles or off centred revolving of tools and workpieces • Adjust accuracy and balance of spindles and check the clamping of the which are poorly fixed may cause vibrations and chattering which could workpiece to prevent off centre revolving and chattering. Use cutting tools cause the tool to break. under recommended cutting conditions. • If cutting tools are not held securely, they may become loose and produce • Make sure, that chucks are always clean and without damages. risk of injuries. Always check if the tool is clamped safely in the chucks before you use the tools.Only use parts which are suitable. 7 MAC • Clamping cutting tools too tightly may cause them to break which may • Only use the recommended tools for clamping cutting under recommend- causes injuries. ed conditions. • Handling machining parts with burrs using bare hands may cause • Wear safety clothes, safety goggles and safety gloves. injuries. • Machines and tools could be damaged if they are used for purposes other • Use them strictly and only for the prescribed application.than the prescribed applications.8 Information: This catalogue contains the basic information for safety handling of our cutting tools. For further information, please contact us. We are not responsible for any accidents caused by modifying tools without our permission. OIL Always wear suitable safety cloth and safety equipment! 9 10 Index 1361 HINES

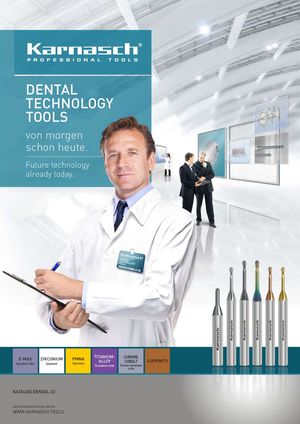

Каталог стоматологического инструмента Karnasch 2021

Каталог стоматологического инструмента Karnasch 2021 Каталог микроинструмента Karnasch 2021

Каталог микроинструмента Karnasch 2021 Каталог магнитных станков Karnasch 2021

Каталог магнитных станков Karnasch 2021 Каталог прямошлифовальные машины Karnasch 2021

Каталог прямошлифовальные машины Karnasch 2021