Каталог Iscar вращающийся инструмент 2017 - страница 601

Навигация

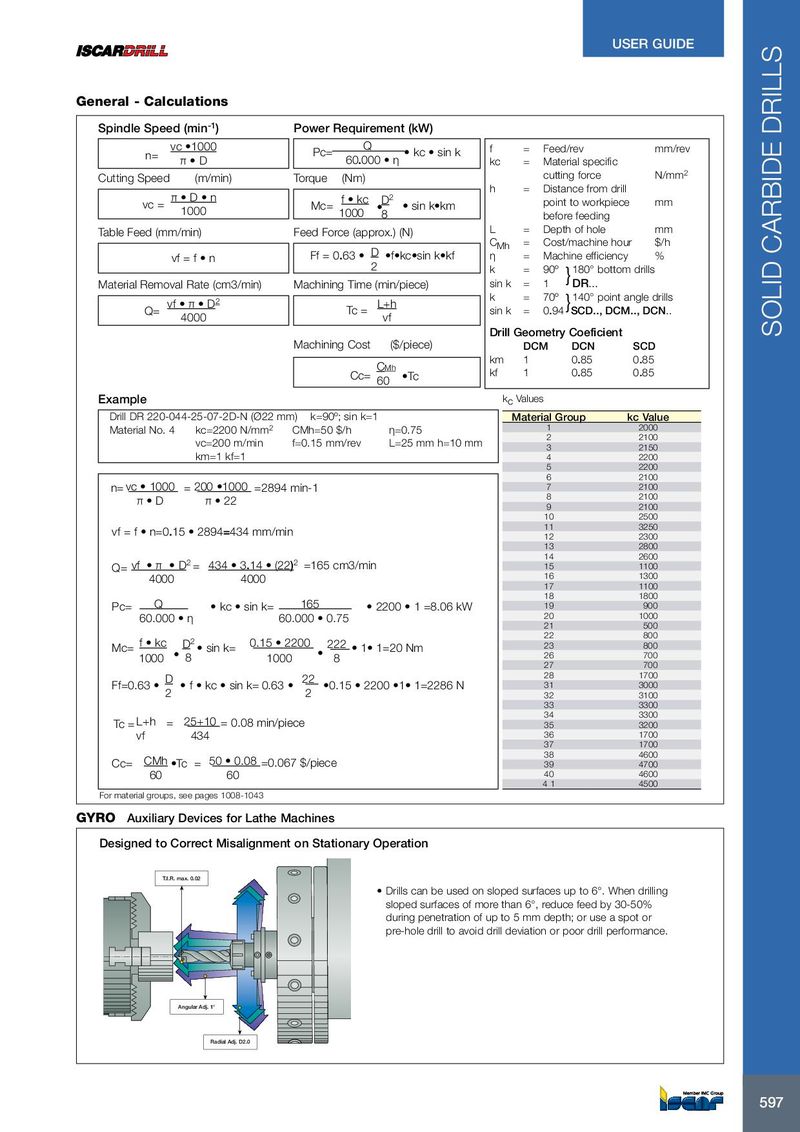

USER GUIDE General - Calculations Spindle Speed (min -1 ) Power Requirement (kW) vc •1000 Q f = Feed/rev mm/rev n= Pc= • kc • sin k π • D 60.000 • η kc = Material specific Cutting Speed (m/min) Torque (Nm) cutting force N/mm 2 h = Distance from drill π • D • n f • kc D 2 vc = point to workpiece mm Mc= 1000 • • sin k•km 1000 8 before feeding Table Feed (mm/min) Feed Force (approx.) (N) L = Depth of hole mm C Mh = Cost/machine hour $/h Ff = 0.63 • D vf = f • n •f•kc•sin k•kf η = Machine efficiency % 2 k = 90º 180° bottom drills } Material Removal Rate (cm3/min) Machining Time (min/piece) sin k = 1 DR... k = 70º 140° point angle drills vf • π • D 2 L+h } Q= Tc = sin k = 0.94 SCD.., DCM.., DCN.. 4000 vf Drill Geometry Coeficient SOLID CARBIDE DRILLS Machining Cost ($/piece) DCM DCN SCD km 1 0.85 0.85 C Mh Cc= •Tc kf 1 0.85 0.85 60 Example k c Values Drill DR 220-044-25-07-2D-N (Ø22 mm) k=90º; sin k=1 Material Group kc Value Material No. 4 kc=2200 N/mm 2 CMh=50 $/h η=0.75 1 2000 2 2100 vc=200 m/min f=0.15 mm/rev L=25 mm h=10 mm 3 2150 km=1 kf=1 4 2200 5 2200 6 2100 n= vc • 1000 = 200 •1000 =2894 min-1 7 2100 8 2100 π • D π • 22 9 2100 10 2500 11 3250 vf = f • n=0.15 • 2894=434 mm/min 12 2300 13 2800 14 2600 Q= vf • π • D 2 = 434 • 3.14 • (22) 2 =165 cm3/min 15 1100 4000 4000 16 1300 17 1100 18 1800 Pc= Q • kc • sin k= 165 • 2200 • 1 =8.06 kW 19 900 60.000 • η 60.000 • 0.75 20 1000 21 500 22 800 f • kc D 2 0.15 • 2200 Mc= • sin k= 222 • 1• 1=20 Nm 23 800 • • 1000 8 1000 26 700 8 27 700 28 1700 D 22 Ff=0.63 • • f • kc • sin k= 0.63 • •0.15 • 2200 •1• 1=2286 N 31 3000 2 2 32 3100 33 3300 34 3300 Tc = L+h = 25+10 = 0.08 min/piece 35 3200 vf 434 36 1700 37 1700 38 4600 Cc= CMh •Tc = 50 • 0.08 =0.067 $/piece 39 4700 60 60 40 4600 4 1 4500 For material groups, see pages 1008-1043 GYRO Auxiliary Devices for Lathe Machines Designed to Correct Misalignment on Stationary Operation T.I.R. max. 0.02 • Drills can be used on sloped surfaces up to 6°. When drilling sloped surfaces of more than 6°, reduce feed by 30-50% during penetration of up to 5 mm depth; or use a spot or pre-hole drill to avoid drill deviation or poor drill performance. Angular Adj. 1° Radial Adj. D2.0 597 597

Каталог Iscar токарные пластины ISO 2022

Каталог Iscar токарные пластины ISO 2022 Каталог Iscar инструмент для фрезерования

Каталог Iscar инструмент для фрезерования Каталог Iscar решения для глубокого сверления

Каталог Iscar решения для глубокого сверления Каталог Iscar полирующие фрезы

Каталог Iscar полирующие фрезы Каталог Iscar новые продукты 2018

Каталог Iscar новые продукты 2018 Каталог Iscar концевые фрезы со сменными пластинами 2022

Каталог Iscar концевые фрезы со сменными пластинами 2022