Каталог Iscar вращающийся инструмент 2017 - страница 560

Навигация

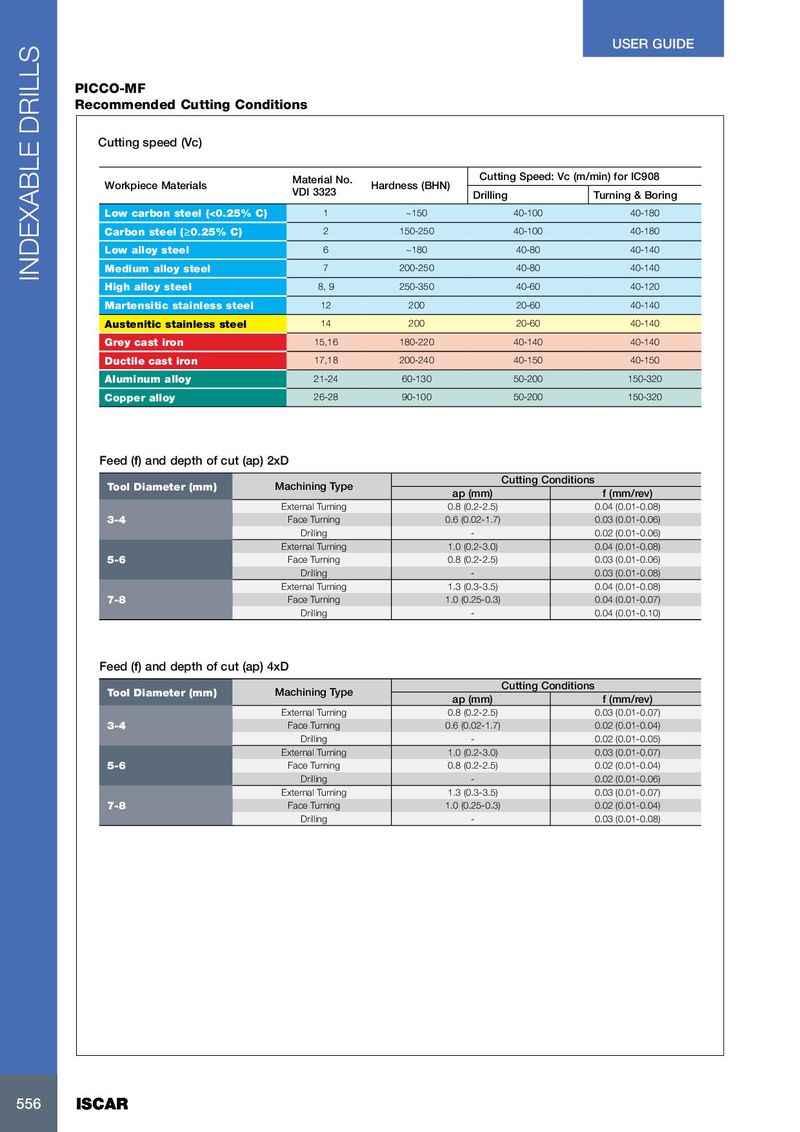

USER GUIDE PICCO-MF Recommended Cutting Conditions Cutting speed (Vc) Material No. Cutting Speed: Vc (m/min) for IC908 Workpiece Materials Hardness (BHN) VDI 3323 Drilling Turning & Boring Low carbon steel (<0.25% C) 1 ~150 40-100 40-180 Carbon steel (≥0.25% C) 2 150-250 40-100 40-180 Low alloy steel 6 ~180 40-80 40-140 Medium alloy steel 7 200-250 40-80 40-140 INDEXABLE DRILLS High alloy steel 8, 9 250-350 40-60 40-120 Martensitic stainless steel 12 200 20-60 40-140 Austenitic stainless steel 14 200 20-60 40-140 Grey cast iron 15,16 180-220 40-140 40-140 Ductile cast iron 17,18 200-240 40-150 40-150 Aluminum alloy 21-24 60-130 50-200 150-320 Copper alloy 26-28 90-100 50-200 150-320 Feed (f) and depth of cut (ap) 2xD Cutting Conditions Tool Diameter (mm) Machining Type ap (mm) f (mm/rev) External Turning 0.8 (0.2-2.5) 0.04 (0.01-0.08) 3-4 Face Turning 0.6 (0.02-1.7) 0.03 (0.01-0.06) Drilling - 0.02 (0.01-0.06) External Turning 1.0 (0.2-3.0) 0.04 (0.01-0.08) 5-6 Face Turning 0.8 (0.2-2.5) 0.03 (0.01-0.06) Drilling - 0.03 (0.01-0.08) External Turning 1.3 (0.3-3.5) 0.04 (0.01-0.08) 7-8 Face Turning 1.0 (0.25-0.3) 0.04 (0.01-0.07) Drilling - 0.04 (0.01-0.10) Feed (f) and depth of cut (ap) 4xD Cutting Conditions Tool Diameter (mm) Machining Type ap (mm) f (mm/rev) External Turning 0.8 (0.2-2.5) 0.03 (0.01-0.07) 3-4 Face Turning 0.6 (0.02-1.7) 0.02 (0.01-0.04) Drilling - 0.02 (0.01-0.05) External Turning 1.0 (0.2-3.0) 0.03 (0.01-0.07) 5-6 Face Turning 0.8 (0.2-2.5) 0.02 (0.01-0.04) Drilling - 0.02 (0.01-0.06) External Turning 1.3 (0.3-3.5) 0.03 (0.01-0.07) 7-8 Face Turning 1.0 (0.25-0.3) 0.02 (0.01-0.04) Drilling - 0.03 (0.01-0.08) 556 556 ISCAR ISCAR

Каталог Iscar токарные пластины ISO 2022

Каталог Iscar токарные пластины ISO 2022 Каталог Iscar инструмент для фрезерования

Каталог Iscar инструмент для фрезерования Каталог Iscar решения для глубокого сверления

Каталог Iscar решения для глубокого сверления Каталог Iscar полирующие фрезы

Каталог Iscar полирующие фрезы Каталог Iscar новые продукты 2018

Каталог Iscar новые продукты 2018 Каталог Iscar концевые фрезы со сменными пластинами 2022

Каталог Iscar концевые фрезы со сменными пластинами 2022