Каталог Iscar вращающийся инструмент 2017 - страница 124

Навигация

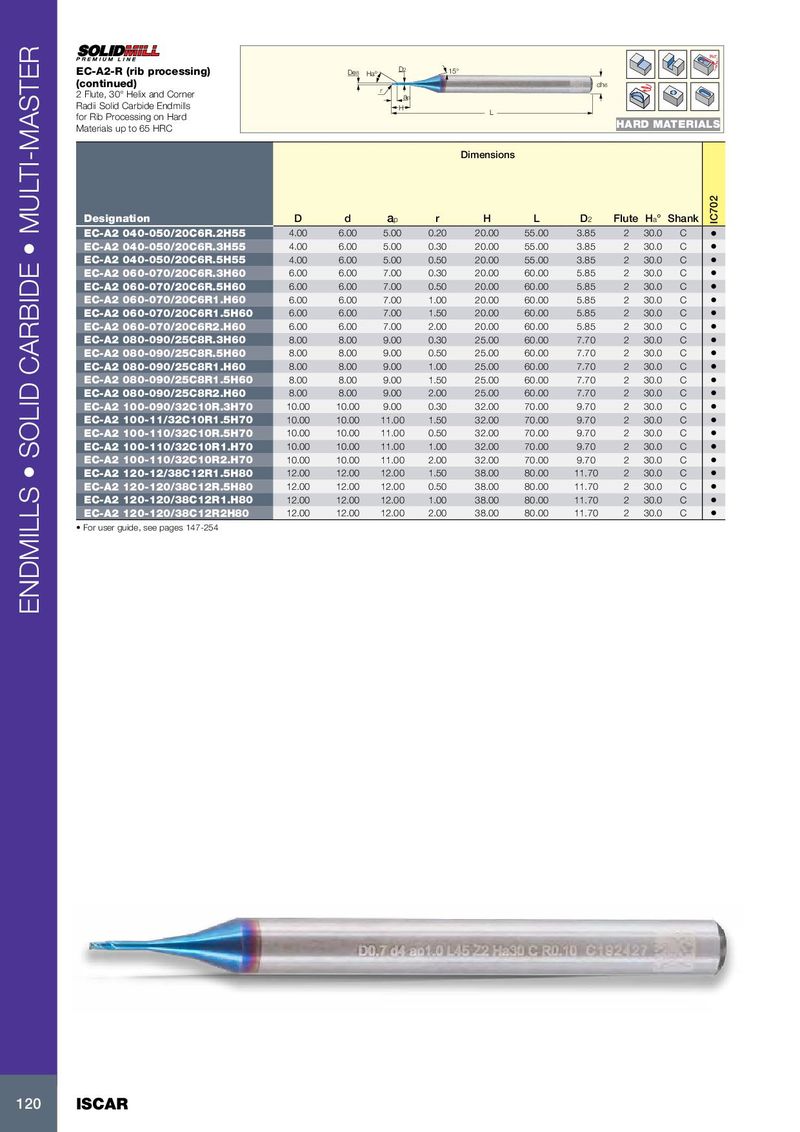

Rd° EC-A2-R (rib processing) De8 D2 Haº 15° (continued) dh6 r 2 Flute, 30° Helix and Corner ap Radii Solid Carbide Endmills H L for Rib Processing on Hard Materials up to 65 HRC HARD MATERIALS Dimensions Designation D d a p r H L D 2 Flute H a ° Shank IC702 EC-A2 040-050/20C6R.2H55 4.00 6.00 5.00 0.20 20.00 55.00 3.85 2 30.0 C • EC-A2 040-050/20C6R.3H55 4.00 6.00 5.00 0.30 20.00 55.00 3.85 2 30.0 C • EC-A2 040-050/20C6R.5H55 4.00 6.00 5.00 0.50 20.00 55.00 3.85 2 30.0 C • EC-A2 060-070/20C6R.3H60 6.00 6.00 7.00 0.30 20.00 60.00 5.85 2 30.0 C • EC-A2 060-070/20C6R.5H60 6.00 6.00 7.00 0.50 20.00 60.00 5.85 2 30.0 C • EC-A2 060-070/20C6R1.H60 6.00 6.00 7.00 1.00 20.00 60.00 5.85 2 30.0 C • EC-A2 060-070/20C6R1.5H60 6.00 6.00 7.00 1.50 20.00 60.00 5.85 2 30.0 C • EC-A2 060-070/20C6R2.H60 6.00 6.00 7.00 2.00 20.00 60.00 5.85 2 30.0 C • EC-A2 080-090/25C8R.3H60 8.00 8.00 9.00 0.30 25.00 60.00 7.70 2 30.0 C • EC-A2 080-090/25C8R.5H60 8.00 8.00 9.00 0.50 25.00 60.00 7.70 2 30.0 C • EC-A2 080-090/25C8R1.H60 8.00 8.00 9.00 1.00 25.00 60.00 7.70 2 30.0 C • EC-A2 080-090/25C8R1.5H60 8.00 8.00 9.00 1.50 25.00 60.00 7.70 2 30.0 C • EC-A2 080-090/25C8R2.H60 8.00 8.00 9.00 2.00 25.00 60.00 7.70 2 30.0 C • EC-A2 100-090/32C10R.3H70 10.00 10.00 9.00 0.30 32.00 70.00 9.70 2 30.0 C • EC-A2 100-11/32C10R1.5H70 10.00 10.00 11.00 1.50 32.00 70.00 9.70 2 30.0 C • EC-A2 100-110/32C10R.5H70 10.00 10.00 11.00 0.50 32.00 70.00 9.70 2 30.0 C • EC-A2 100-110/32C10R1.H70 10.00 10.00 11.00 1.00 32.00 70.00 9.70 2 30.0 C • EC-A2 100-110/32C10R2.H70 10.00 10.00 11.00 2.00 32.00 70.00 9.70 2 30.0 C • EC-A2 120-12/38C12R1.5H80 12.00 12.00 12.00 1.50 38.00 80.00 11.70 2 30.0 C • EC-A2 120-120/38C12R.5H80 12.00 12.00 12.00 0.50 38.00 80.00 11.70 2 30.0 C • EC-A2 120-120/38C12R1.H80 12.00 12.00 12.00 1.00 38.00 80.00 11.70 2 30.0 C • EC-A2 120-120/38C12R2H80 12.00 12.00 12.00 2.00 38.00 80.00 11.70 2 30.0 C • • For user guide, see pages 147-254 ENDMILLS • SOLID CARBIDE • MULTI-MASTER 120 ISCAR

Каталог Iscar токарные пластины ISO 2022

Каталог Iscar токарные пластины ISO 2022 Каталог Iscar инструмент для фрезерования

Каталог Iscar инструмент для фрезерования Каталог Iscar решения для глубокого сверления

Каталог Iscar решения для глубокого сверления Каталог Iscar полирующие фрезы

Каталог Iscar полирующие фрезы Каталог Iscar новые продукты 2018

Каталог Iscar новые продукты 2018 Каталог Iscar концевые фрезы со сменными пластинами 2022

Каталог Iscar концевые фрезы со сменными пластинами 2022