Каталог Iscar вращающийся инструмент 2017 - страница 1006

Навигация

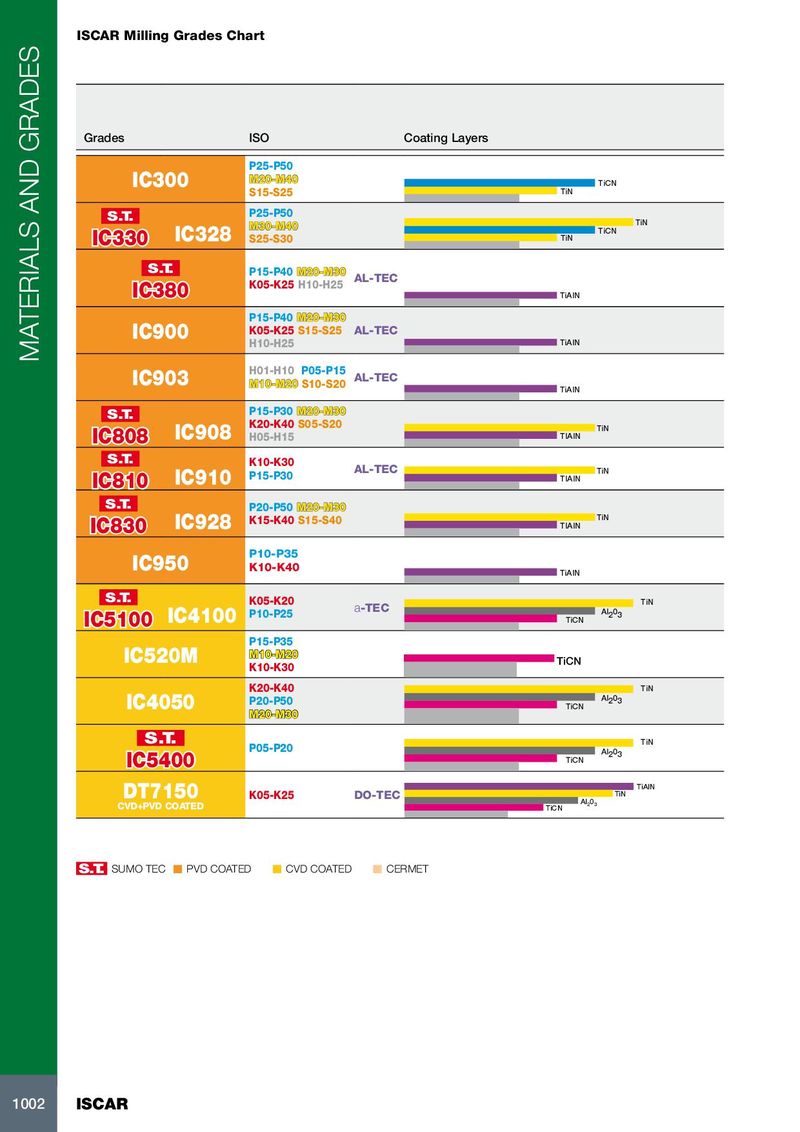

ISCAR Milling Grades Chart Grades ISO Coating Layers Recommended Applications P25-P50 A tough submicron TiN/TiCN PVD coated grade. Suitable for milling heat resistant alloys, austenitic M20-M40 IC300 TiCN stainless steel and carbon steel at unfavorable conditions, at low to medium cutting speeds. S15-S25 TiN S.T. P25-P50 TiN A TiN/TiCN PVD coated tough grade. Used for milling, grooving, parting and drilling a M30-M40 TiCN wide range of workpiece materials, at low to medium cutting speeds. IC330 IC328 S25-S30 TiN A tough submicron substrate, TiCN PVD coated and a special surface treatment. Designed for S.T. P15-P40 M20-M30 machining titanium and heat resistant alloys, austenitic stainless steel, at medium to high cutting speeds, AL-TEC K05-K25 H10-H25 interrupted cut and unfavorable conditions. Excellent notch wear and built-up edge resistance. High IC380 TiAIN resistance to mechanical and thermal shock – therefore milling with coolant may be applied. P15-P40 M20-M30 A tough, submicron PVD TiAlN coated grade. Suitable for milling heat resistant alloys, austenitic K05-K25 S15-S25 AL-TEC IC900 H10-H25 TiAIN stainless steel, hard alloys and carbon steel at medium to high cutting speeds. MATERIALS AND GRADES H01-H10 P05-P15 Ultra-fine grain carbide with 12% cobalt, TiAlN PVD coated grade. Used for up to 62 HRc hardened steel, titanium, AL-TEC IC903 M10-M20 S10-S20 TiAIN nickel-based alloys and stainless steel at high speeds and medium feeds. A tough and highly wear resistant grade. A tough submicron substrate, TiAlN PVD coated grade. Designed for machining heat resistant alloys, S.T. P15-P30 M20-M30 K20-K40 S05-S20 TiN austenitic stainless steel, hard alloys and carbon steel at medium to high cutting speeds, interrupted IC808 IC908 H05-H15 TIAIN cut and unfavorable conditions. Excellent notch wear and built-up edge resistance. S.T. K10-K30 AL-TEC TiN A PVD TiAlN coated grade. First choice for milling nodular cast iron at medium to high cutting speeds. P15-P30 IC810 IC910 TIAIN S.T. P20-P50 M20-M30 A PVD TiAlN coated tough grade. Suitable for milling stainless steel, high temperature alloys and other alloy steels. K15-K40 S15-S40 TiN TIAIN Recommended for interrupted cut and heavy operations. IC830 IC928 P10-P35 A PVD TiAlN coated grade. Used for heavy milling alloy steel and cast iron. Features excellent wear resistance. IC950 K10-K40 TiAIN S.T. K05-K20 TiN A tough substrate with a new MTCVD and TiCN/Al2O3 coating. Recommended for a-TEC P10-P25 Al 2 0 3 milling grey cast iron at high cutting speeds, providing extended tool life. IC5100 IC4100 TiCN P15-P35 A TiCN CVD coated grade. Used for milling and drilling steel, malleable cast iron and M10-M20 IC520M TiCN stainless steel at medium feeds and medium to high cutting speeds. K10-K30 K20-K40 TiN Al A TiCN/TiC/Al2O3 multilayer, CVD coated grade. Used for milling grey and nodular cast P20-P50 2 0 3 IC4050 TiCN iron, at medium to high cutting speeds. A high wear resistant grade. M20-M30 S.T. TiN A tough substrate with a new MTCVD and alpha Al2O3 coating. Recommended for milling steel at high cutting speed providing P05-P20 Al 2 0 3 TiCN excellent tool life. IC5400 TiAIN A tough substrate with a dual MTCVD Al2O3 and TiAlN PVD coating. Recommended for medium to high cutting DT7150 K05-K25 DO-TEC TiN Al CVD+PVD COATED speeds for machining of both grey and nodular cast iron. Features high wear and chipping resistance. TiCN 2 0 3 S.T. SUMO TEC PVD COATED CVD COATED CERMET 1002 ISCAR

Каталог Iscar токарные пластины ISO 2022

Каталог Iscar токарные пластины ISO 2022 Каталог Iscar инструмент для фрезерования

Каталог Iscar инструмент для фрезерования Каталог Iscar решения для глубокого сверления

Каталог Iscar решения для глубокого сверления Каталог Iscar полирующие фрезы

Каталог Iscar полирующие фрезы Каталог Iscar новые продукты 2018

Каталог Iscar новые продукты 2018 Каталог Iscar концевые фрезы со сменными пластинами 2022

Каталог Iscar концевые фрезы со сменными пластинами 2022