Каталог Iscar токарный инструмент 2017 - страница 565

Навигация

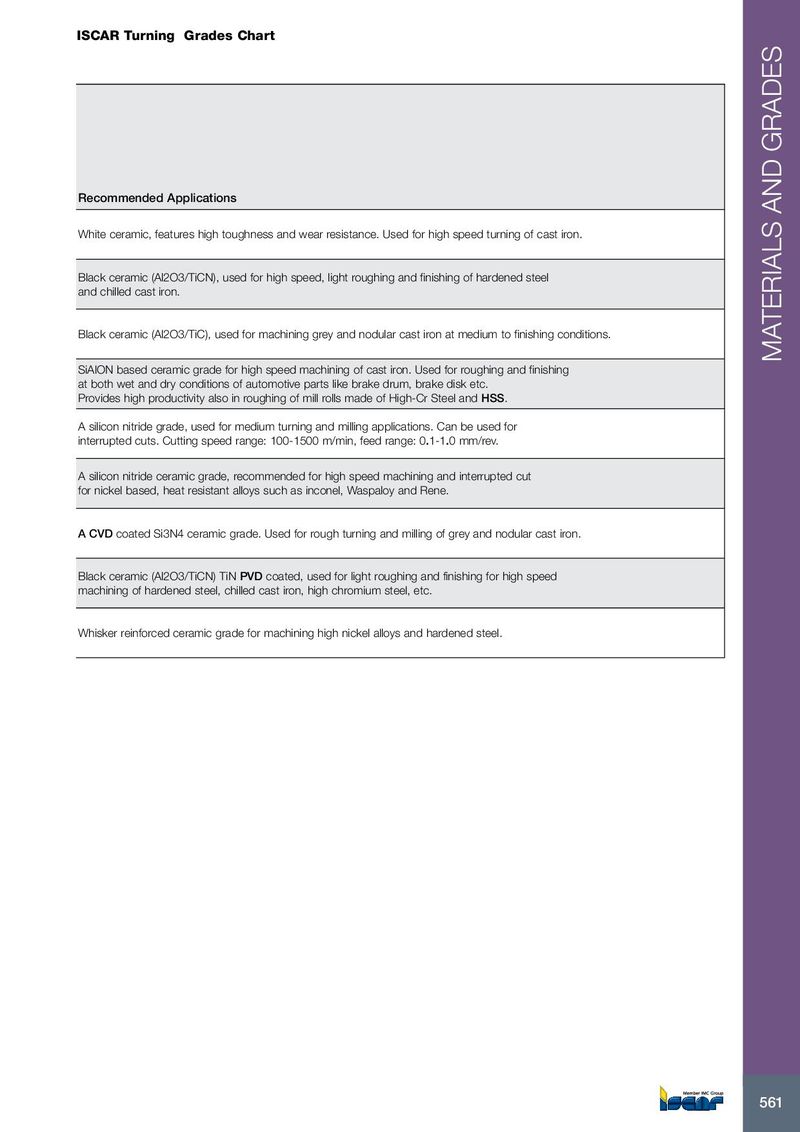

ISCAR Turning Grades Chart Recommended Applications White ceramic, features high toughness and wear resistance. Used for high speed turning of cast iron. Black ceramic (Al2O3/TiCN), used for high speed, light roughing and finishing of hardened steel and chilled cast iron. Black ceramic (Al2O3/TiC), used for machining grey and nodular cast iron at medium to finishing conditions. MATERIALS AND GRADES SiAlON based ceramic grade for high speed machining of cast iron. Used for roughing and finishing at both wet and dry conditions of automotive parts like brake drum, brake disk etc. Provides high productivity also in roughing of mill rolls made of High-Cr Steel and HSS. A silicon nitride grade, used for medium turning and milling applications. Can be used for interrupted cuts. Cutting speed range: 100-1500 m/min, feed range: 0.1-1.0 mm/rev. A silicon nitride ceramic grade, recommended for high speed machining and interrupted cut for nickel based, heat resistant alloys such as inconel, Waspaloy and Rene. A CVD coated Si3N4 ceramic grade. Used for rough turning and milling of grey and nodular cast iron. Black ceramic (Al2O3/TiCN) TiN PVD coated, used for light roughing and finishing for high speed machining of hardened steel, chilled cast iron, high chromium steel, etc. Whisker reinforced ceramic grade for machining high nickel alloys and hardened steel. 561

Каталог Iscar резьбонарезные фрезы

Каталог Iscar резьбонарезные фрезы Каталог Iscar инструмент для обработки алюминиевых колёс

Каталог Iscar инструмент для обработки алюминиевых колёс Каталог Iscar державки и пластины для нарезания резьбы 2022

Каталог Iscar державки и пластины для нарезания резьбы 2022 Каталог Iscar расточные системы 2022

Каталог Iscar расточные системы 2022 Каталог Iscar высокоточные развертки и метчики 2022

Каталог Iscar высокоточные развертки и метчики 2022 Каталог Iscar вращающийся инструмент 2017

Каталог Iscar вращающийся инструмент 2017