Каталог Iscar токарный инструмент 2017 - страница 561

Навигация

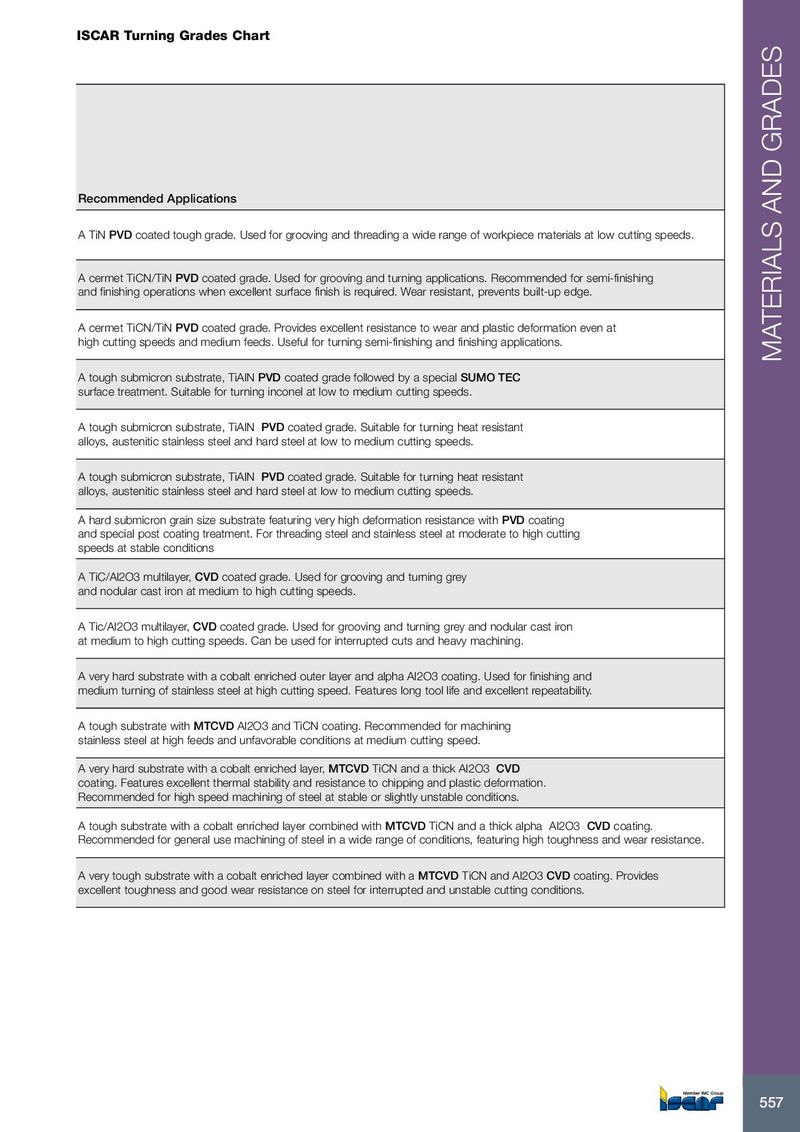

ISCAR Turning Grades Chart Recommended Applications A TiN PVD coated tough grade. Used for grooving and threading a wide range of workpiece materials at low cutting speeds. A cermet TiCN/TiN PVD coated grade. Used for grooving and turning applications. Recommended for semi-finishing and finishing operations when excellent surface finish is required. Wear resistant, prevents built-up edge. A cermet TiCN/TiN PVD coated grade. Provides excellent resistance to wear and plastic deformation even at high cutting speeds and medium feeds. Useful for turning semi-finishing and finishing applications. MATERIALS AND GRADES A tough submicron substrate, TiAlN PVD coated grade followed by a special SUMO TEC surface treatment. Suitable for turning inconel at low to medium cutting speeds. A tough submicron substrate, TiAlN PVD coated grade. Suitable for turning heat resistant alloys, austenitic stainless steel and hard steel at low to medium cutting speeds. A tough submicron substrate, TiAlN PVD coated grade. Suitable for turning heat resistant alloys, austenitic stainless steel and hard steel at low to medium cutting speeds. A hard submicron grain size substrate featuring very high deformation resistance with PVD coating and special post coating treatment. For threading steel and stainless steel at moderate to high cutting speeds at stable conditions A TiC/Al2O3 multilayer, CVD coated grade. Used for grooving and turning grey and nodular cast iron at medium to high cutting speeds. A Tic/Al2O3 multilayer, CVD coated grade. Used for grooving and turning grey and nodular cast iron at medium to high cutting speeds. Can be used for interrupted cuts and heavy machining. A very hard substrate with a cobalt enriched outer layer and alpha Al2O3 coating. Used for finishing and medium turning of stainless steel at high cutting speed. Features long tool life and excellent repeatability. A tough substrate with MTCVD Al2O3 and TiCN coating. Recommended for machining stainless steel at high feeds and unfavorable conditions at medium cutting speed. A very hard substrate with a cobalt enriched layer, MTCVD TiCN and a thick Al2O3 CVD coating. Features excellent thermal stability and resistance to chipping and plastic deformation. Recommended for high speed machining of steel at stable or slightly unstable conditions. A tough substrate with a cobalt enriched layer combined with MTCVD TiCN and a thick alpha Al2O3 CVD coating. Recommended for general use machining of steel in a wide range of conditions, featuring high toughness and wear resistance. A very tough substrate with a cobalt enriched layer combined with a MTCVD TiCN and Al2O3 CVD coating. Provides excellent toughness and good wear resistance on steel for interrupted and unstable cutting conditions. 557

Каталог Iscar резьбонарезные фрезы

Каталог Iscar резьбонарезные фрезы Каталог Iscar инструмент для обработки алюминиевых колёс

Каталог Iscar инструмент для обработки алюминиевых колёс Каталог Iscar державки и пластины для нарезания резьбы 2022

Каталог Iscar державки и пластины для нарезания резьбы 2022 Каталог Iscar расточные системы 2022

Каталог Iscar расточные системы 2022 Каталог Iscar высокоточные развертки и метчики 2022

Каталог Iscar высокоточные развертки и метчики 2022 Каталог Iscar вращающийся инструмент 2017

Каталог Iscar вращающийся инструмент 2017