Каталог Iscar токарный инструмент 2017 - страница 546

Навигация

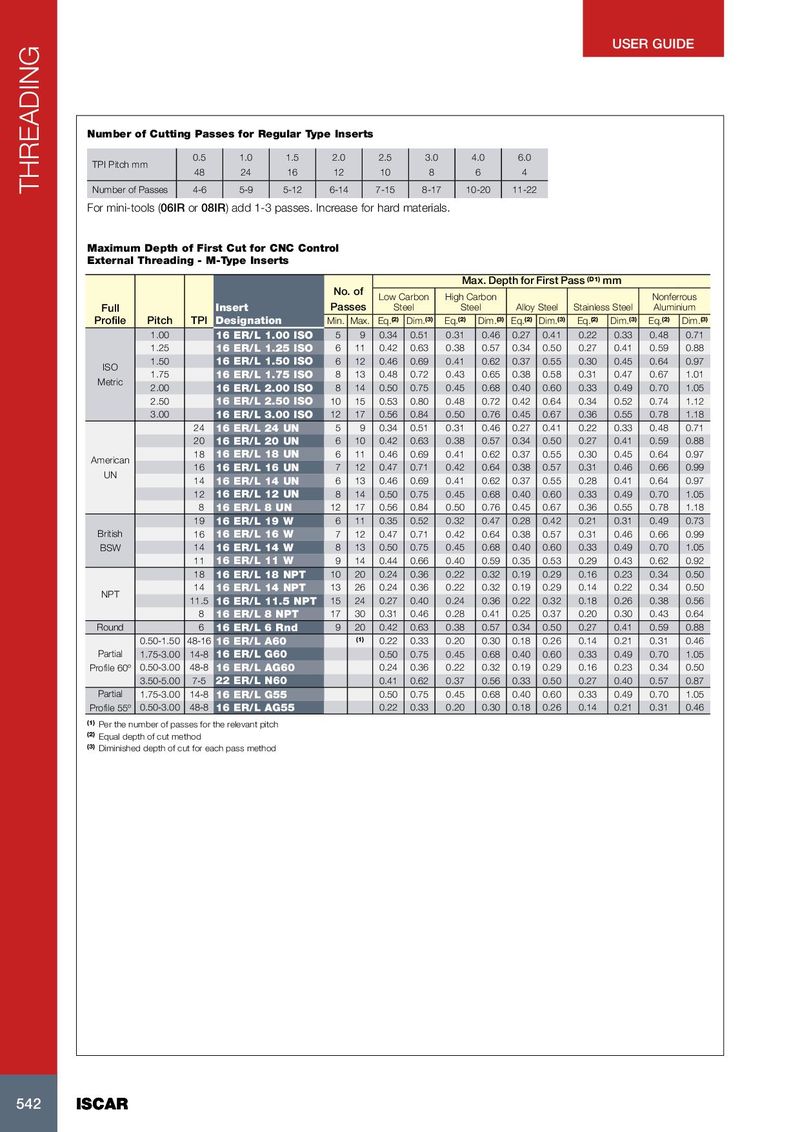

USER GUIDE Number of Cutting Passes for Regular Type Inserts 0.5 1.0 1.5 2.0 2.5 3.0 4.0 6.0 TPI Pitch mm 48 24 16 12 10 8 6 4 THREADING Number of Passes 4-6 5-9 5-12 6-14 7-15 8-17 10-20 11-22 For mini-tools (06IR or 08IR) add 1-3 passes. Increase for hard materials. Maximum Depth of First Cut for CNC Control External Threading - M-Type Inserts Max. Depth for First Pass (D1) mm No. of Low Carbon High Carbon Nonferrous Full Insert Passes Steel Steel Alloy Steel Stainless Steel Aluminium Profile Pitch TPI Designation Min. Max. Eq. (2) Dim. (3) Eq. (2) Dim. (3) Eq. (2) Dim. (3) Eq. (2) Dim. (3) Eq. (2) Dim. (3) 1.00 16 ER/L 1.00 ISO 5 9 0.34 0.51 0.31 0.46 0.27 0.41 0.22 0.33 0.48 0.71 1.25 16 ER/L 1.25 ISO 6 11 0.42 0.63 0.38 0.57 0.34 0.50 0.27 0.41 0.59 0.88 1.50 16 ER/L 1.50 ISO 6 12 0.46 0.69 0.41 0.62 0.37 0.55 0.30 0.45 0.64 0.97 ISO 1.75 16 ER/L 1.75 ISO 8 13 0.48 0.72 0.43 0.65 0.38 0.58 0.31 0.47 0.67 1.01 Metric 2.00 16 ER/L 2.00 ISO 8 14 0.50 0.75 0.45 0.68 0.40 0.60 0.33 0.49 0.70 1.05 2.50 16 ER/L 2.50 ISO 10 15 0.53 0.80 0.48 0.72 0.42 0.64 0.34 0.52 0.74 1.12 3.00 16 ER/L 3.00 ISO 12 17 0.56 0.84 0.50 0.76 0.45 0.67 0.36 0.55 0.78 1.18 24 16 ER/L 24 UN 5 9 0.34 0.51 0.31 0.46 0.27 0.41 0.22 0.33 0.48 0.71 20 16 ER/L 20 UN 6 10 0.42 0.63 0.38 0.57 0.34 0.50 0.27 0.41 0.59 0.88 18 16 ER/L 18 UN 6 11 0.46 0.69 0.41 0.62 0.37 0.55 0.30 0.45 0.64 0.97 American 16 16 ER/L 16 UN 7 12 0.47 0.71 0.42 0.64 0.38 0.57 0.31 0.46 0.66 0.99 UN 14 16 ER/L 14 UN 6 13 0.46 0.69 0.41 0.62 0.37 0.55 0.28 0.41 0.64 0.97 12 16 ER/L 12 UN 8 14 0.50 0.75 0.45 0.68 0.40 0.60 0.33 0.49 0.70 1.05 8 16 ER/L 8 UN 12 17 0.56 0.84 0.50 0.76 0.45 0.67 0.36 0.55 0.78 1.18 19 16 ER/L 19 W 6 11 0.35 0.52 0.32 0.47 0.28 0.42 0.21 0.31 0.49 0.73 British 16 16 ER/L 16 W 7 12 0.47 0.71 0.42 0.64 0.38 0.57 0.31 0.46 0.66 0.99 BSW 14 16 ER/L 14 W 8 13 0.50 0.75 0.45 0.68 0.40 0.60 0.33 0.49 0.70 1.05 11 16 ER/L 11 W 9 14 0.44 0.66 0.40 0.59 0.35 0.53 0.29 0.43 0.62 0.92 18 16 ER/L 18 NPT 10 20 0.24 0.36 0.22 0.32 0.19 0.29 0.16 0.23 0.34 0.50 14 16 ER/L 14 NPT 13 26 0.24 0.36 0.22 0.32 0.19 0.29 0.14 0.22 0.34 0.50 NPT 11.5 16 ER/L 11.5 NPT 15 24 0.27 0.40 0.24 0.36 0.22 0.32 0.18 0.26 0.38 0.56 8 16 ER/L 8 NPT 17 30 0.31 0.46 0.28 0.41 0.25 0.37 0.20 0.30 0.43 0.64 Round 6 16 ER/L 6 Rnd 9 20 0.42 0.63 0.38 0.57 0.34 0.50 0.27 0.41 0.59 0.88 0.50-1.50 48-16 16 ER/L A60 (1) 0.22 0.33 0.20 0.30 0.18 0.26 0.14 0.21 0.31 0.46 Partial 1.75-3.00 14-8 16 ER/L G60 0.50 0.75 0.45 0.68 0.40 0.60 0.33 0.49 0.70 1.05 Profile 60º 0.50-3.00 48-8 16 ER/L AG60 0.24 0.36 0.22 0.32 0.19 0.29 0.16 0.23 0.34 0.50 3.50-5.00 7-5 22 ER/L N60 0.41 0.62 0.37 0.56 0.33 0.50 0.27 0.40 0.57 0.87 Partial 1.75-3.00 14-8 16 ER/L G55 0.50 0.75 0.45 0.68 0.40 0.60 0.33 0.49 0.70 1.05 Profile 55º 0.50-3.00 48-8 16 ER/L AG55 0.22 0.33 0.20 0.30 0.18 0.26 0.14 0.21 0.31 0.46 (1) Per the number of passes for the relevant pitch (2) Equal depth of cut method (3) Diminished depth of cut for each pass method 542 542 ISCAR ISCAR

Каталог Iscar резьбонарезные фрезы

Каталог Iscar резьбонарезные фрезы Каталог Iscar инструмент для обработки алюминиевых колёс

Каталог Iscar инструмент для обработки алюминиевых колёс Каталог Iscar державки и пластины для нарезания резьбы 2022

Каталог Iscar державки и пластины для нарезания резьбы 2022 Каталог Iscar расточные системы 2022

Каталог Iscar расточные системы 2022 Каталог Iscar высокоточные развертки и метчики 2022

Каталог Iscar высокоточные развертки и метчики 2022 Каталог Iscar вращающийся инструмент 2017

Каталог Iscar вращающийся инструмент 2017