Каталог Iscar токарный инструмент 2017 - страница 372

Навигация

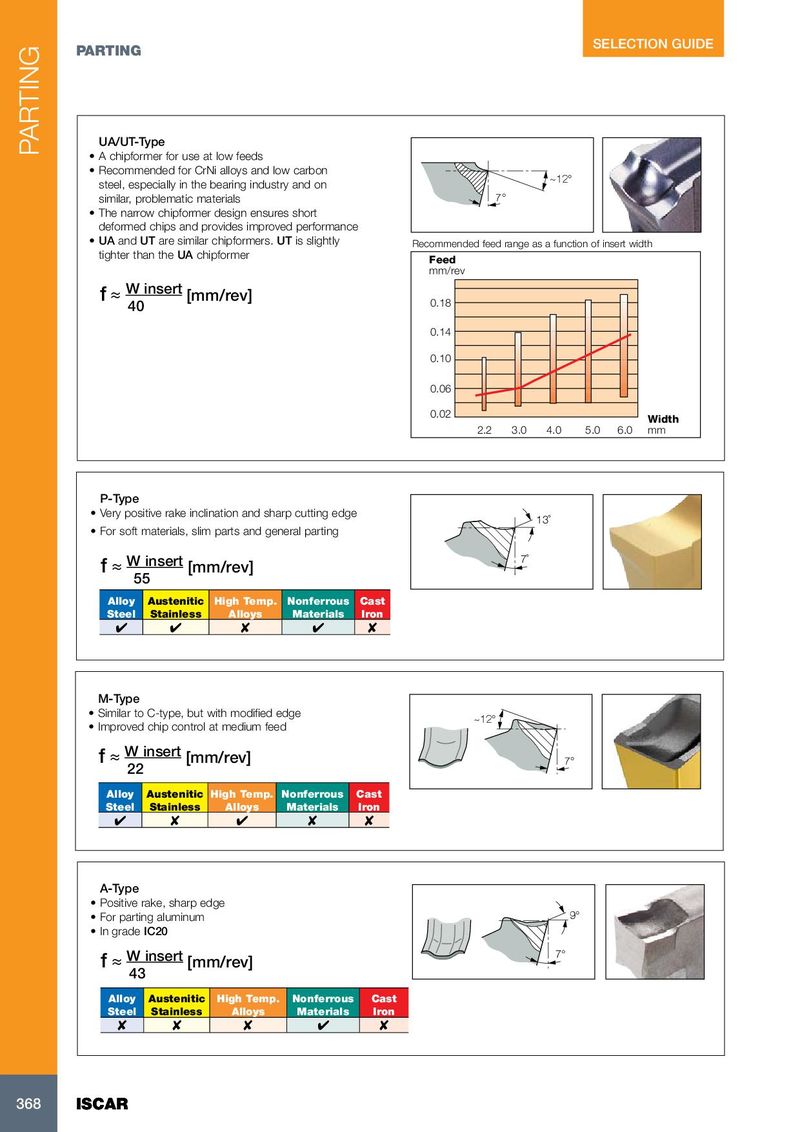

SELECTION GUIDE PARTING UA/UT-Type PARTING • A chipformer for use at low feeds • Recommended for CrNi alloys and low carbon ~12° steel, especially in the bearing industry and on similar, problematic materials 7° • The narrow chipformer design ensures short deformed chips and provides improved performance • UA and UT are similar chipformers. UT is slightly Recommended feed range as a function of insert width tighter than the UA chipformer Feed mm/rev W insert f ≈ [mm/rev] 0.18 40 0.14 0.10 0.06 0.02 Width 2.2 3.0 4.0 5.0 6.0 mm P-Type • Very positive rake inclination and sharp cutting edge 13˚ • For soft materials, slim parts and general parting W insert 7˚ f ≈ [mm/rev] 55 Alloy Austenitic High Temp. Nonferrous Cast Steel Stainless Alloys Materials Iron ✔ ✔ ✘ ✔ ✘ M-Type • Similar to C-type, but with modified edge ~12° • Improved chip control at medium feed W insert f ≈ [mm/rev] 7° 22 Alloy Austenitic High Temp. Nonferrous Cast Steel Stainless Alloys Materials Iron ✔ ✘ ✔ ✘ ✘ A-Type • Positive rake, sharp edge • For parting aluminum 9° • In grade IC20 W insert 7° f ≈ [mm/rev] 43 Alloy Austenitic High Temp. Nonferrous Cast Steel Stainless Alloys Materials Iron ✘ ✘ ✘ ✔ ✘ 368 368 ISCAR ISCAR

Каталог Iscar резьбонарезные фрезы

Каталог Iscar резьбонарезные фрезы Каталог Iscar инструмент для обработки алюминиевых колёс

Каталог Iscar инструмент для обработки алюминиевых колёс Каталог Iscar державки и пластины для нарезания резьбы 2022

Каталог Iscar державки и пластины для нарезания резьбы 2022 Каталог Iscar расточные системы 2022

Каталог Iscar расточные системы 2022 Каталог Iscar высокоточные развертки и метчики 2022

Каталог Iscar высокоточные развертки и метчики 2022 Каталог Iscar вращающийся инструмент 2017

Каталог Iscar вращающийся инструмент 2017