Каталог Iscar токарный инструмент 2017 - страница 296

Навигация

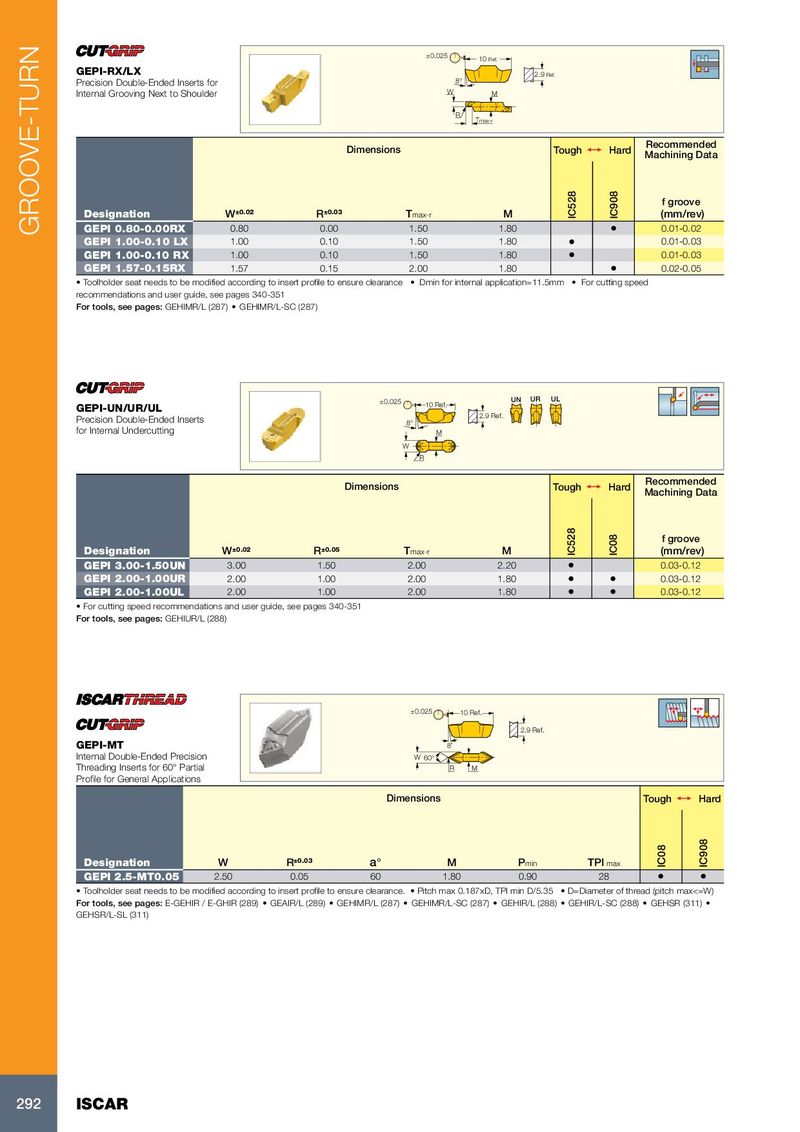

±0.025 10 Ref. GEPI-RX/LX 2.9 Ref. Precision Double-Ended Inserts for 8° Internal Grooving Next to Shoulder W M R Tmax-r Recommended Dimensions Tough 1 Hard Machining Data f groove Designation W ±0.02 R ±0.03 T max-r M IC528 IC908 (mm/rev) GROOVE-TURN GEPI 0.80-0.00RX 0.80 0.00 1.50 1.80 • 0.01-0.02 GEPI 1.00-0.10 LX 1.00 0.10 1.50 1.80 • 0.01-0.03 GEPI 1.00-0.10 RX 1.00 0.10 1.50 1.80 • 0.01-0.03 GEPI 1.57-0.15RX 1.57 0.15 2.00 1.80 • 0.02-0.05 • Toolholder seat needs to be modified according to insert profile to ensure clearance • Dmin for internal application=11.5mm • For cutting speed recommendations and user guide, see pages 340-351 For tools, see pages: GEHIMR/L (287) • GEHIMR/L-SC (287) ±0.025 UN UR UL 10 Ref. GEPI-UN/UR/UL 2.9 Ref. Precision Double-Ended Inserts 8° for Internal Undercutting M W R Recommended Dimensions Tough 1 Hard Machining Data f groove Designation W ±0.02 R ±0.05 T max-r M IC528 IC08 (mm/rev) GEPI 3.00-1.50UN 3.00 1.50 2.00 2.20 • 0.03-0.12 GEPI 2.00-1.00UR 2.00 1.00 2.00 1.80 • • 0.03-0.12 GEPI 2.00-1.00UL 2.00 1.00 2.00 1.80 • • 0.03-0.12 • For cutting speed recommendations and user guide, see pages 340-351 For tools, see pages: GEHIUR/L (288) ±0.025 10 Ref. 2.9 Ref. GEPI-MT 8˚ Internal Double-Ended Precision W 60° Threading Inserts for 60° Partial R M Profile for General Applications Dimensions Tough 1 Hard Designation W R ±0.03 a° M P min TPI max IC08 IC908 GEPI 2.5-MT0.05 2.50 0.05 60 1.80 0.90 28 • • • Toolholder seat needs to be modified according to insert profile to ensure clearance. • Pitch max 0.187xD, TPI min D/5.35 • D=Diameter of thread (pitch max<=W) For tools, see pages: E-GEHIR / E-GHIR (289) • GEAIR/L (289) • GEHIMR/L (287) • GEHIMR/L-SC (287) • GEHIR/L (288) • GEHIR/L-SC (288) • GEHSR (311) • GEHSR/L-SL (311) 292 ISCAR

Каталог Iscar резьбонарезные фрезы

Каталог Iscar резьбонарезные фрезы Каталог Iscar инструмент для обработки алюминиевых колёс

Каталог Iscar инструмент для обработки алюминиевых колёс Каталог Iscar державки и пластины для нарезания резьбы 2022

Каталог Iscar державки и пластины для нарезания резьбы 2022 Каталог Iscar расточные системы 2022

Каталог Iscar расточные системы 2022 Каталог Iscar высокоточные развертки и метчики 2022

Каталог Iscar высокоточные развертки и метчики 2022 Каталог Iscar вращающийся инструмент 2017

Каталог Iscar вращающийся инструмент 2017