Каталог Iscar токарный инструмент 2017 - страница 222

Навигация

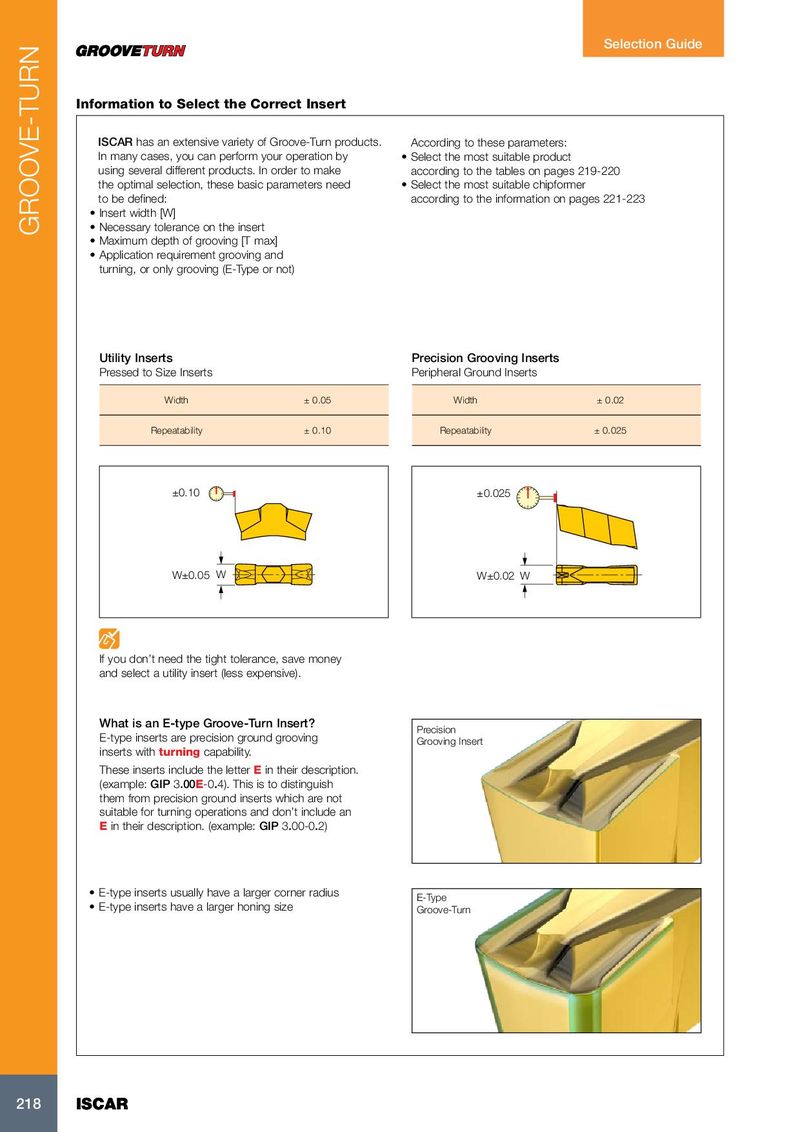

Selection Guide Information to Select the Correct Insert ISCAR has an extensive variety of Groove-Turn products. According to these parameters: In many cases, you can perform your operation by • Select the most suitable product using several different products. In order to make according to the tables on pages 219-220 the optimal selection, these basic parameters need • Select the most suitable chipformer to be defined: according to the information on pages 221-223 • Insert width [W] • Necessary tolerance on the insert GROOVE-TURN • Maximum depth of grooving [T max] • Application requirement grooving and turning, or only grooving (E-Type or not) Utility Inserts Precision Grooving Inserts Pressed to Size Inserts Peripheral Ground Inserts Width ± 0.05 Width ± 0.02 Repeatability ± 0.10 Repeatability ± 0.025 ±0.10 ±0.025 W±0.05 W W±0.02 W If you don’t need the tight tolerance, save money and select a utility insert (less expensive). What is an E-type Groove-Turn Insert? Precision E-type inserts are precision ground grooving Grooving Insert inserts with turning capability. These inserts include the letter E in their description. (example: GIP 3.00E-0.4). This is to distinguish them from precision ground inserts which are not suitable for turning operations and don’t include an E in their description. (example: GIP 3.00-0.2) • E-type inserts usually have a larger corner radius E-Type • E-type inserts have a larger honing size Groove-Turn 218 218 ISCAR ISCAR

Каталог Iscar резьбонарезные фрезы

Каталог Iscar резьбонарезные фрезы Каталог Iscar инструмент для обработки алюминиевых колёс

Каталог Iscar инструмент для обработки алюминиевых колёс Каталог Iscar державки и пластины для нарезания резьбы 2022

Каталог Iscar державки и пластины для нарезания резьбы 2022 Каталог Iscar расточные системы 2022

Каталог Iscar расточные системы 2022 Каталог Iscar высокоточные развертки и метчики 2022

Каталог Iscar высокоточные развертки и метчики 2022 Каталог Iscar вращающийся инструмент 2017

Каталог Iscar вращающийся инструмент 2017