Каталог Iscar токарный инструмент 2017 - страница 212

Навигация

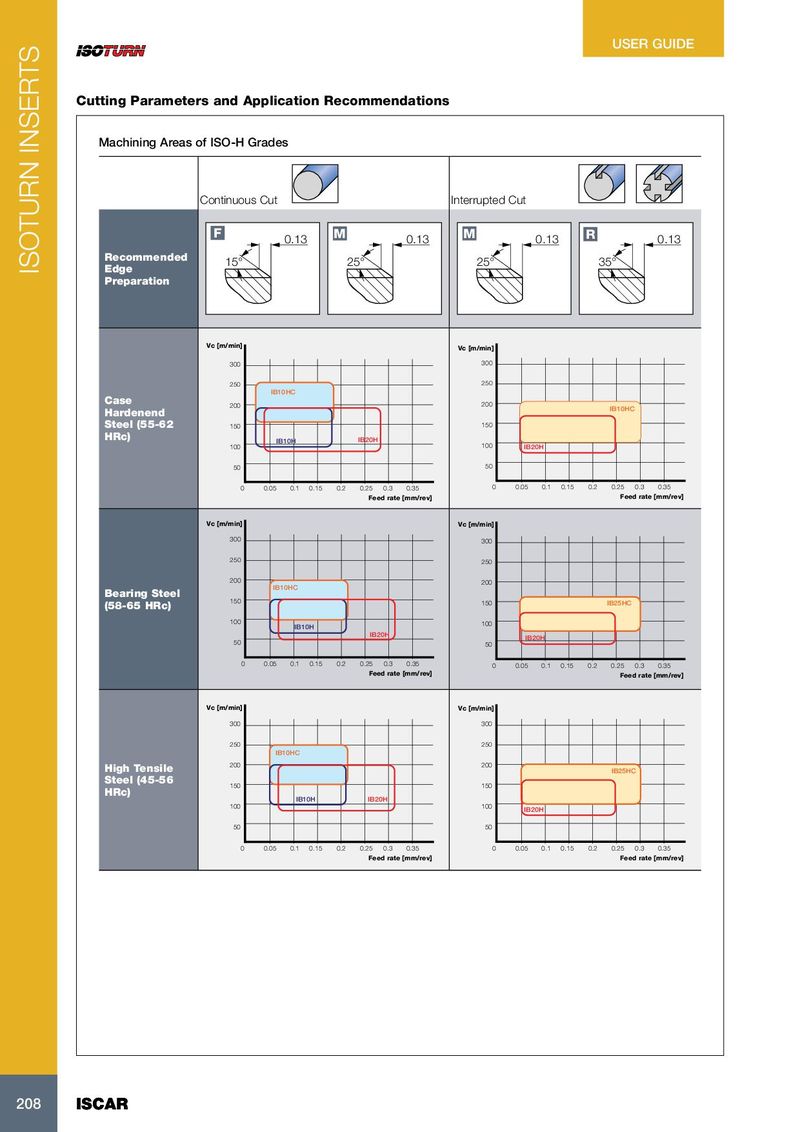

USER GUIDE Cutting Parameters and Application Recommendations Machining Areas of ISO-H Grades Continuous Cut Interrupted Cut F M M R 0.13 0.13 0.13 0.13 Recommended 15° 25° 25° 35° ISOTURN INSERTS Edge Preparation Vc [m/min] Vc [m/min] 300 300 250 250 IB10HC Case 200 200 IB10HC Hardenend Steel (55-62 150 150 HRc) IB10H IB20H 100 100 IB20H 50 50 0 0.05 0.1 0.15 0.2 0.25 0.3 0.35 0 0.05 0.1 0.15 0.2 0.25 0.3 0.35 Feed rate [mm/rev] Feed rate [mm/rev] Vc [m/min] Vc [m/min] 300 300 250 250 200 200 IB10HC Bearing Steel 150 (58-65 HRc) 150 IB25HC 100 IB10H 100 IB20H IB20H 50 50 0 0.05 0.1 0.15 0.2 0.25 0.3 0.35 0 0.05 0.1 0.15 0.2 0.25 0.3 0.35 Feed rate [mm/rev] Feed rate [mm/rev] Vc [m/min] Vc [m/min] 300 300 250 250 IB10HC High Tensile 200 200 IB25HC Steel (45-56 150 150 HRc) IB10H IB20H 100 100 IB20H 50 50 0 0.05 0.1 0.15 0.2 0.25 0.3 0.35 0 0.05 0.1 0.15 0.2 0.25 0.3 0.35 Feed rate [mm/rev] Feed rate [mm/rev] 208 208 ISCAR ISCAR

Каталог Iscar резьбонарезные фрезы

Каталог Iscar резьбонарезные фрезы Каталог Iscar инструмент для обработки алюминиевых колёс

Каталог Iscar инструмент для обработки алюминиевых колёс Каталог Iscar державки и пластины для нарезания резьбы 2022

Каталог Iscar державки и пластины для нарезания резьбы 2022 Каталог Iscar расточные системы 2022

Каталог Iscar расточные системы 2022 Каталог Iscar высокоточные развертки и метчики 2022

Каталог Iscar высокоточные развертки и метчики 2022 Каталог Iscar вращающийся инструмент 2017

Каталог Iscar вращающийся инструмент 2017