Каталог Iscar токарный инструмент 2017 - страница 205

Навигация

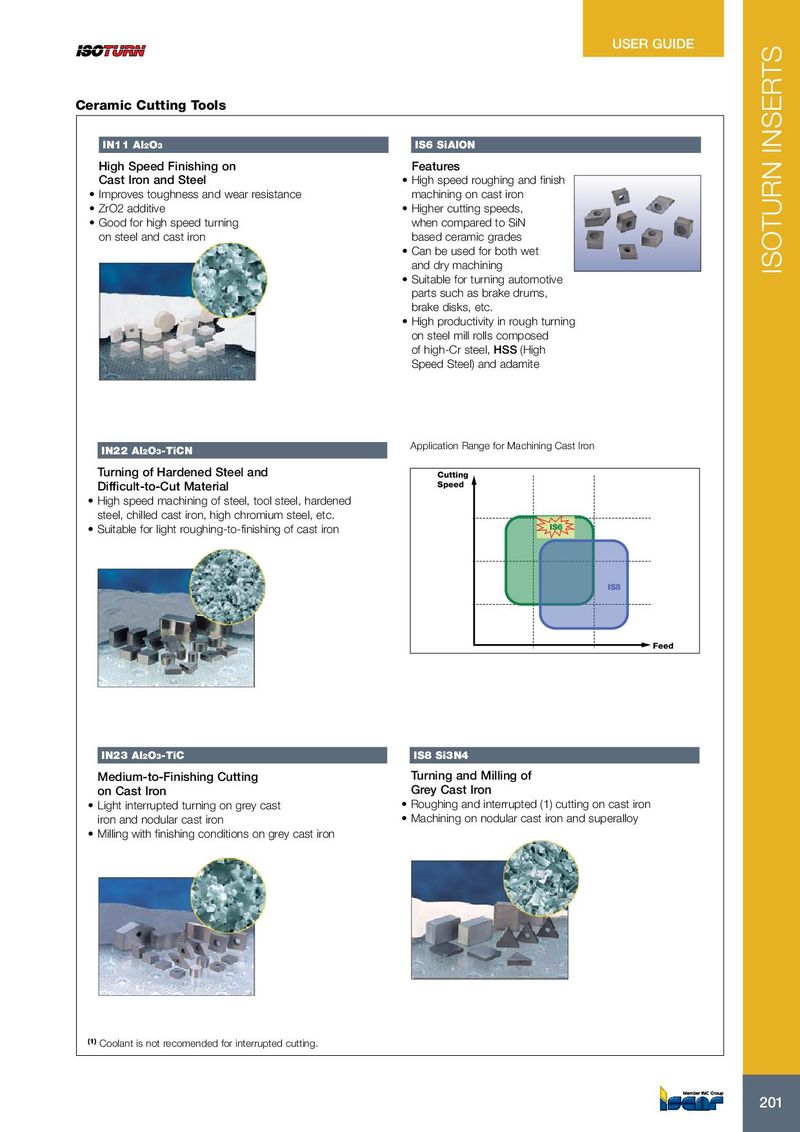

USER GUIDE Ceramic Cutting Tools IN11 Al 2 O 3 IS6 SiAlON High Speed Finishing on Features Cast Iron and Steel • High speed roughing and finish • Improves toughness and wear resistance machining on cast iron • ZrO2 additive • Higher cutting speeds, • Good for high speed turning when compared to SiN on steel and cast iron based ceramic grades • Can be used for both wet and dry machining ISOTURN INSERTS • Suitable for turning automotive parts such as brake drums, brake disks, etc. • High productivity in rough turning on steel mill rolls composed of high-Cr steel, HSS (High Speed Steel) and adamite Application Range for Machining Cast Iron IN22 Al 2 O 3 -TiCN Turning of Hardened Steel and Cutting Difficult-to-Cut Material Speed • High speed machining of steel, tool steel, hardened steel, chilled cast iron, high chromium steel, etc. • Suitable for light roughing-to-finishing of cast iron IS6 IS8 Feed IN23 Al 2 O 3 -TiC IS8 Si3N4 Medium-to-Finishing Cutting Turning and Milling of on Cast Iron Grey Cast Iron • Light interrupted turning on grey cast • Roughing and interrupted (1) cutting on cast iron iron and nodular cast iron • Machining on nodular cast iron and superalloy • Milling with finishing conditions on grey cast iron (1) Coolant is not recomended for interrupted cutting. 201 201

Каталог Iscar резьбонарезные фрезы

Каталог Iscar резьбонарезные фрезы Каталог Iscar инструмент для обработки алюминиевых колёс

Каталог Iscar инструмент для обработки алюминиевых колёс Каталог Iscar державки и пластины для нарезания резьбы 2022

Каталог Iscar державки и пластины для нарезания резьбы 2022 Каталог Iscar расточные системы 2022

Каталог Iscar расточные системы 2022 Каталог Iscar высокоточные развертки и метчики 2022

Каталог Iscar высокоточные развертки и метчики 2022 Каталог Iscar вращающийся инструмент 2017

Каталог Iscar вращающийся инструмент 2017