Каталог Iscar сверла со сменной режущей частью 2022 - страница 140

Навигация

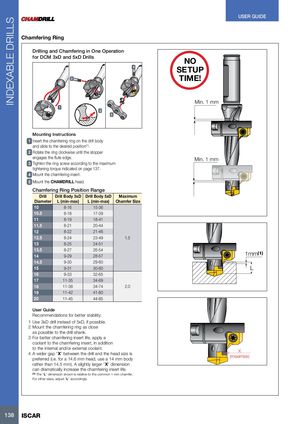

INDEXABLE DRILLS USER GUIDE Chamfering Ring Drilling and Chamfering in One Operation for DCM 3xD and 5xD Drills NO 4 SETUP 3 TIME! Min. 1 mm 1 2 5 Mounting Instructions 1 Insert the chamfering ring on the drill body and slide to the desired position(1). 2 Rotate the ring clockwise until the stopper engages the flute edge. Min. 1 mm 3 Tighten the ring screw according to the maximum tightening torque indicated on page 137. 4 Mount the chamfering insert. 5 Mount the CHAMDRILL head. Chamfering Ring Position Range Drill Drill Body 3xD Drill Body 5xD Maximum Diameter L (min-max) L (min-max) Chamfer Size 10 8-16 15-36 10.5 8-18 17-39 11 8-19 18-41 11.5 8-21 20-44 12 8-22 21-46 12.5 8-24 23-49 1.5 13 8-25 24-51 13.5 8-27 26-54149-2928-57 1mm(1) 14.5 9-30 29-60 15 9-31 30-60 L 16 9-33 32-65 17 11-35 34-69 18 11-38 34-74 2.0 19 11-42 41-80 20 11-45 44-85 User Guide Recommendations for better stability: 1 Use 3xD drill instead of 5xD, if possible. 2 Mount the chamfering ring as close as possible to the drill shank. 3 For better chamfering insert life, apply a coolant to the chamfering insert, in addition to the internal and/or external coolant.4 A wider gap “X” between the drill and the head size ispreferred (i.e. for a 14.6 mm head, use a 14 mm bodyX(maximize) rather than 14.5 mm). A slightly larger “X” dimension can dramatically increase the chamfering insert life. (1) The “L” dimension shown is relative to the common 1 mm chamfer. For other sizes, adjust “L” accordingly. 138 ISCAR

Каталог Iscar монолитные фрезы 2022

Каталог Iscar монолитные фрезы 2022 Каталог Iscar токарный инструмент

Каталог Iscar токарный инструмент Каталог Iscar инструмент для мелкоразмерной обработки

Каталог Iscar инструмент для мелкоразмерной обработки Каталог Iscar токарный инструмент для нарезания канавок

Каталог Iscar токарный инструмент для нарезания канавок Каталог Iscar полирующие фрезы

Каталог Iscar полирующие фрезы Каталог Iscar дисковые фрезы и фрезерные пластины 2022

Каталог Iscar дисковые фрезы и фрезерные пластины 2022