Каталог Iscar расточные системы 2022 - страница 95

Навигация

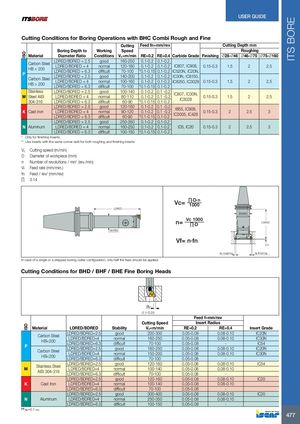

ISOISO .0015 ITS BORE USER GUIDE Cutting Conditions for Boring Operations with BHC Combi Rough and Fine Cutting Feed fn=mm/rev Cutting Depth mm Boring Depth to Working Speed Roughing Material Diameter Ratio Conditions Vc=m/min RE=0.2 RE=0.4 Carbide Grade Finishing Ø28-Ø46 Ø46-Ø75 Ø75-Ø160 P Carbon SteelHB < 200Carbon SteelHB > 200LDRED/BDRED = 2.5LDRED/BDRED = 4LDRED/BDRED = 6.3LDRED/BDRED = 2.5LDRED/BDRED = 4LDRED/BDRED = 6.3goodnormaldifficultgoodnormaldifficult160-250 0.1-0.2 0.1-0.2120-1800.1-0.20.1-0.2IC807, IC908,0.15-0.370-100*0.1-0.150.1-0.2IC520N, IC20N,140-2000.1-0.20.1-0.2IC30N, IC8150,100-1600.1-0.20.1-0.2IC8250, IC30280.15-0.370-100*0.1-0.150.1-0.21.51.5222.52.5 Stainless LDRED/BDRED = 2.5 goodMSteel AISILDRED/BDRED = 4normal304-316LDRED/BDRED = 6.3difficult100-14080-11060-90 0.1-0.2 0.1 -0.20.1-0.20.1 -0.2*0.1-0.150.1-0.2IC807, IC30N,IC30280.15-0.31.5 2 2.5 K Cast Iron LDRED/BDRED = 2.5 goodLDRED/BDRED = 4normalLDRED/BDRED = 6.3difficult120-16090-12060-90 0.1-0.2 0.1 -0.20.1-0.20.1 -0.2*0.1-0.150.1-0.2IB55, IC908,IC5005, IC4280.15-0.322.5 3 LDRED/BDRED = 2.5 good 250-350 0.1-0.2 0.1-0.2 N Aluminum LDRED/BDRED = 4 normal 160-250 0.1-0.2 0.1-0.2 ID5, IC20 0.15-0.3 2 2.5 3 LDRED/BDRED = 6.3 difficult 100-150 *0.1-0.15 0.1-0.2 * Only for finishing Inserts. ** Use inserts with the same corner radii for both roughing and finishing inserts Vc Cutting speed (m/min) D Diameter of workpiece (mm) n Number of revolutions / min' (rev./min) Vf Feed rate (mm/min.) fn Feed / rev/ (mm/rev) ∏ 3.14 Vc= ∏·D·n1000 LDRED BDRED 0 n= Vc 1000∏·D LDRED BDRED Vf= n·fn 0.2 ap roughing ap finishing In case of a single or a stepped boring cutter configuration, only half the feed should be applied. Cutting Conditions for BHD / BHF / BHE Fine Boring Heads ap 0.1-0.25 Feed f=mm/rev Cutting Speed Insert Radius Material LDRED/BDRED Stability Vc=m/min RE=0.2 RE=0.4 Insert Grade P Carbon SteelHB<200 LDRED/BDRED=2.5LDRED/BDRED=4LDRED/BDRED=6.3Carbon SteelHB<200LDRED/BDRED=2.5LDRED/BDRED=4LDRED/BDRED=6.3goodnormaldifficultgoodnormaldifficult 200-300 0.05-0.08 0.08-0.10160-2500.05-0.080.08-0.1070-1000.05-0.08-160-2500.05-0.080.08-0.10150-2000.05-0.080.08-0.1070-1000.05-0.08-IC20NIC30NIC54IC20NIC30N M Stainless SteelAISI 304-316LDRED/BDRED=2.5LDRED/BDRED=4LDRED/BDRED=6.3goodnormaldifficult 120-160 0.05-0.08 0.08-0.10100-1400.05-0.080.08-0.1070-1000.05-0.08-IC54 LDRED/BDRED=2.5 good 120-160 0.05-0.08 0.08-0.10 IC20 K Cast Iron LDRED/BDRED=4 normal 100-140 0.05-0.08 0.08-0.10 LDRED/BDRED=6.3 difficult 70-100 0.05-0.08 - LDRED/BDRED=2.5 good 300-400 0.05-0.08 0.08-0.10 IC20 N Aluminum LDRED/BDRED=4 normal 250-350 0.05-0.08 0.08-0.10 LDRED/BDRED=6.3 difficult 100-150 0.05-0.08 - (1) ap=0.1 min 477 .0005 .001

Каталог Iscar дисковые фрезы и фрезерные пластины 2022

Каталог Iscar дисковые фрезы и фрезерные пластины 2022 Каталог Iscar монолитные концевые фрезы и система multi-master

Каталог Iscar монолитные концевые фрезы и система multi-master Каталог Iscar расточные системы

Каталог Iscar расточные системы Каталог Iscar крепление инструмента

Каталог Iscar крепление инструмента Каталог Iscar решения для глубокого сверления

Каталог Iscar решения для глубокого сверления Каталог Iscar инструмента для сверления

Каталог Iscar инструмента для сверления