Каталог Iscar расточные системы 2022 - страница 108

Навигация

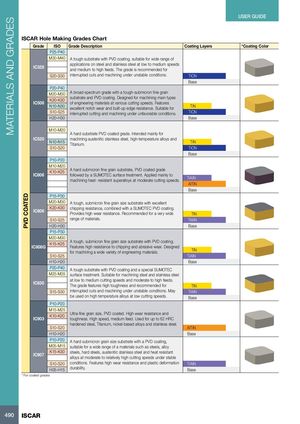

MATERIALS AND GRADES PVD COATED USER GUIDE ISCAR Hole Making Grades Chart Grade ISO Grade Description Coating Layers *Coating Color P25-P40 M30-M40 A tough substrate with PVD coating, suitable for wide range of IC328 applications on steel and stainless steel at low to medium speedsand medium to high feeds. The grade is recommended for S20-S30 interrupted cuts and machining under unstable conditions. TiCN Base P20-P40 M20-M30 A broad-spectrum grade with a tough-submicron fine grain IC508 K20-K30N10-N30substrate and PVD coating. Designed for machining main typesof engineering materials at various cutting speeds. Featuresexcellent notch wear and built-up edge resistance. Suitable forTiN S10-S25 interrupted cutting and machining under unfavorable conditions. TiCN H20-H30 Base M10-M20 A hard substrate PVD coated grade. Intended mainly for IC520 N10-N15 machining austenitic stainless steel, high-temperature alloys andTitanium.TiN S10-S20 TiCN Base P10-P20 M10-M20 IC806 K10-K25 A hard submicron fine grain substrate, PVD coated gradefollowed by a SUMOTEC surface treatment. Applied mainly tomachining heat- resistant superalloys at moderate cutting speeds.TiAIN AlTiN Base P15-P30 M20-M30 A tough, submicron fine grain size substrate with excellent IC808 K20-K30 chipping resistance, combined with a SUMOTEC PVD coating.Provides high wear resistance. Recommended for a very wideTiN S10-S25 range of materials. TiAIN H20-H30 Base P15-P30 M20-M30 IC808G K15-K25 A tough, submicron fine grain size substrate with PVD coating.Features high resistance to chipping and abrasive wear. Designed for machining a wide variety of engineering materials. TiN S10-S25 TiAlN H10-H20 Base P20-P40 A tough substrate with PVD coating and a special SUMOTEC M25-M35 surface treatment. Suitable for machining steel and stainless steel IC830 at low to medium cutting speeds and moderate to high feeds.The grade features high toughness and recommended forTiN S15-S30 interrupted cuts and machining under unstable conditions. May TiAlN be used on high temperature alloys at low cutting speeds. Base P10-P20 M15-M25 IC903 K10-K20 Ultra-fine grain size, PVD coated. High wear resistance andtoughness. High speed, medium feed. Used for up to 62 HRC hardened steel, Titanium, nickel-based alloys and stainless steel. S10-S20 AlTiN H10-H20 Base P10-P20 A hard submicron grain size substrate with a PVD coating, M05-M15 suitable for a wide range of a materials such as steels, alloy IC907 K15-K30 steels, hard steels, austenitic stainless steel and heat resistantalloys at moderate to relatively high cutting speeds under stable S10-S20 conditions. Features high wear resistance and plastic deformation TiAlN H05-H15 durability. Base * For coated grades 490 ISCAR

Каталог Iscar дисковые фрезы и фрезерные пластины 2022

Каталог Iscar дисковые фрезы и фрезерные пластины 2022 Каталог Iscar монолитные концевые фрезы и система multi-master

Каталог Iscar монолитные концевые фрезы и система multi-master Каталог Iscar расточные системы

Каталог Iscar расточные системы Каталог Iscar крепление инструмента

Каталог Iscar крепление инструмента Каталог Iscar решения для глубокого сверления

Каталог Iscar решения для глубокого сверления Каталог Iscar инструмента для сверления

Каталог Iscar инструмента для сверления