Каталог Iscar отрезка 2022 - страница 146

Навигация

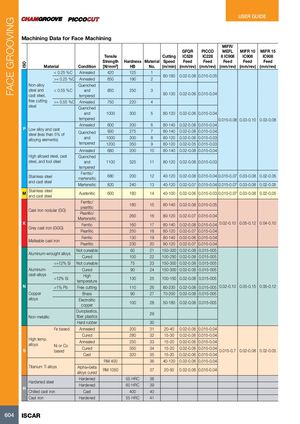

FACE GROOVING ISO USER GUIDE Machining Data for Face Machining MIFR/ GFQR PICCO MEFL MIFR 10 MIFR 15 Tensile Cutting IC528 IC228 8 IC908 IC908 IC908 Strength Hardness Material Speed Feed Feed Feed Feed Feed Material Condition [N/mm2] HB No. (m/min) (mm/rev) (mm/rev) (mm/rev) (mm/rev) (mm/rev) < 0.25 %C Annealed 420 125 1 80-180 0.02-0.08 0.015-0.05 >= 0.25 %C Annealed 650 190 2 Non-alloy Quenched steel and < 0.55 %C and 850 250 3 cast steel, tempered 80-130 0.02-0.06 0.015-0.04 free cutting >= 0.55 %C Annealed 750 220 4 steel Quenched and 1000 300 5 80-120 0.02-0.06 0.015-0.04 tempered 0.015-0.08 0.03-0.10 0.03-0.08 Annealed 600 200 6 80-140 0.02-0.08 0.015-0.04 P Low alloy and caststeel (less than 5% ofQuenched930 275 7 80-140 0.02-0.08 0.015-0.04 alloying elements) and 1000 300 8 80-120 0.02-0.06 0.015-0.03 tempered 1200 350 9 80-120 0.02-0.05 0.015-0.03 Annealed 680 200 10 80-140 0.02-0.08 0.015-0.04 High alloyed steel, cast Quenched steel, and tool steel and 1100 325 11 80-120 0.02-0.08 0.015-0.03 tempered Stainless steel Ferritic/martensitic680 200 12 40-120 0.02-0.08 0.015-0.04 0.015-0.07 0.03-0.08 0.02-0.05 and cast steel Martensitic 820 240 13 40-120 0.02-0.07 0.015-0.04 0.015-0.07 0.03-0.08 0.02-0.05 M Stainless steeland cast steel Austenitic 600 180 14 40-100 0.02-0.06 0.015-0.03 0.015-0.07 0.03-0.08 0.02-0.05 Ferritic/pearlitic 180 15 80-140 0.02-0.08 0.015-0.05 Cast iron nodular (GG) Pearlitic/Martensitic 260 16 80-120 0.02-0.07 0.015-0.04 K Ferritic 160 17 80-140 0.02-0.08 0.015-0.04 0.02-0.10 0.05-0.12 0.04-0.10 Grey cast iron (GGG) Pearlitic 250 18 80-120 0.02-0.07 0.015-0.04 Ferritic 130 19 80-140 0.02-0.06 0.015-0.04 Malleable cast iron Pearlitic 230 20 80-120 0.02-0.07 0.015-0.04 Not cureable 60 21 150-320 0.02-0.08 0.015-005 Aluminum-wrought alloys Cured 100 22 100-250 0.02-0.08 0.015-005 <=12% Si Not cureable 75 23 150-300 0.02-0.08 0.015-005 Aluminum- Cured 90 24 150-300 0.02-0.08 0.015-005 cast-alloys >12% Si Hightemperature 130 25 100-150 0.02-0.08 0.015-005 N >1% Pb Free cutting 110 26 80-230 0.02-0.08 0.015-005 0.02-0.10 0.05-0.15 0.05-0.12 Copper Brass 90 27 70-200 0.02-0.08 0.015-005 alloys Electroliticcopper 100 28 50-180 0.02-0.08 0.015-005 Duroplastics,Non-metallicfiber plastics 29 Hard rubber 30 Fe based Annealed 200 31 20-40 0.02-0.06 0.015-0.04 Cured 280 32 15-30 0.02-0.06 0.015-0.04 High temp.alloysNi or CoSbasedAnnealedCured 250 33 15-20 0.02-0.06 0.015-0.043503415-200.02-0.060.015-0.040.015-0.70.02-0.080.02-0.05 Cast 320 35 15-20 0.02-0.06 0.015-0.04 RM 400 36 40-120 0.02-0.06 0.015-0.04 Titanium Ti alloys Alpha+betaalloys curedRM 1050 37 20-50 0.02-0.06 0.015-0.04 Hardened 55 HRC 38 Hardened steel Hardened 60 HRC 39 H Chilled cast iron Cast 400 40 Cast iron Hardened 55 HRC 41 604 ISCAR

Каталог Iscar монолитные фрезы 2022

Каталог Iscar монолитные фрезы 2022 Каталог Iscar резьбонарезные фрезы

Каталог Iscar резьбонарезные фрезы Каталог Iscar расточные системы

Каталог Iscar расточные системы Каталог Iscar токарный инструмент 2017

Каталог Iscar токарный инструмент 2017 Каталог Iscar инструмент для фрезерования

Каталог Iscar инструмент для фрезерования Каталог Iscar высокоточные развертки и метчики 2022

Каталог Iscar высокоточные развертки и метчики 2022