Каталог Iscar обработка канавок 2022 - страница 101

Навигация

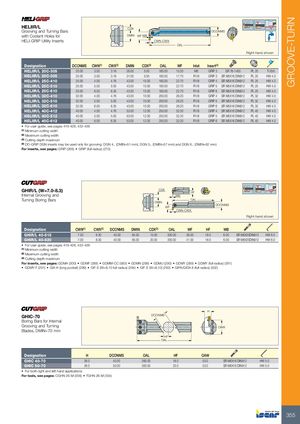

GROOVE-TURN HELIIR/L CDX Grooving and Turning Bars DCONMS with Coolant Holes for DMIN WF WB HELI-GRIP Utility Inserts CWN-CWX OAL Right-hand shown Designation DCONMS CWN(1) CWX(2) DMIN CDX(3) OAL WF Inlet Insert(4) HELIIR/L 20C-305 20.00 3.00 3.18 26.00 5.00 160.00 15.20 M6 GRIP 3 SR 76-1400 PL 20 T-20/5 HELIIR/L 25C-305 25.00 3.00 3.18 31.00 5.00 160.00 17.70 R1/8 GRIP 3 SR M5X16 DIN912 PL 25 HW 4.0 HELIIR/L 25C-410 25.00 4.00 4.76 43.00 10.00 160.00 22.70 R1/8 GRIP 4 SR M5X16 DIN912 PL 25 HW 4.0 HELIIR/L 25C-510 25.00 5.00 5.00 43.00 10.00 160.00 22.70 R1/8 GRIP 5 SR M5X16 DIN912 PL 25 HW 4.0 HELIIR/L 25C-610 25.00 6.00 6.35 43.00 10.00 160.00 22.70 R1/8 GRIP 6 SR M5X16 DIN912 PL 25 HW 4.0 HELIIR/L 32C-410 32.00 4.00 4.76 43.00 10.00 200.00 26.20 R1/8 GRIP 4 SR M5X16 DIN912 PL 32 HW 4.0 HELIIR/L 32C-510 32.00 5.00 5.00 43.00 10.00 200.00 26.20 R1/8 GRIP 5 SR M5X16 DIN912 PL 32 HW 4.0 HELIIR/L 32C-610 32.00 6.00 6.35 43.00 10.00 200.00 26.20 R1/8 GRIP 6 SR M5X16 DIN912 PL 32 HW 4.0 HELIIR/L 40C-412 40.00 4.00 4.76 53.00 12.00 250.00 32.20 R1/8 GRIP 4 SR M5X16 DIN912 PL 40 HW 4.0 HELIIR/L 40C-512 40.00 5.00 5.00 53.00 12.00 250.00 32.20 R1/8 GRIP 5 SR M5X16 DIN912 PL 40 HW 4.0 HELIIR/L 40C-612 40.00 6.00 6.35 53.00 12.00 250.00 32.20 R1/8 GRIP 6 SR M5X16 DIN912 PL 40 HW 4.0 • For user guide, see pages 419-428, 432-436 (1) Minimum cutting width (2) Maximum cutting width (3) Cutting depth maximum (4) DO-GRIP DGN inserts may be used only for grooving: DGN 4.. (DMIN=51 mm), DGN 5.. (DMIN=57 mm) and DGN 6.. (DMIN=62 mm) For inserts, see pages: GRIP (269) • GRIP (full radius) (270) GHIR/L (W=7.0-8.3) CDX HF Internal Grooving and WB Turning Boring Bars OALDMIN WF DCONMS CWN-CWX Right-hand shown Designation CWN(1) CWX(2) DCONMS DMIN CDX(3) OAL WF HF WB GHIR/L 40-815 7.00 8.30 40.00 64.00 15.00 300.00 36.00 18.0 6.00 SR M8X20DIN912 HW 6.0 GHIR/L 40-820 7.00 8.30 40.00 65.00 20.00 300.00 41.00 18.0 6.00 SR M8X20DIN912 HW 6.0 • For user guide, see pages 419-428, 432-436 (1) Minimum cutting width (2) Maximum cutting width (3) Cutting depth maximum For inserts, see pages: GDMA (300) • GDMF (288) • GDMM-CC (583) • GDMN (289) • GDMU (290) • GDMY (289) • GDMY (full radius) (291) • GDMY-F (291) • GIA-K (long pocket) (299) • GIF-E (W=8,10 full radius) (294) • GIF-E (W=8,10) (292) • GIPA/GIDA 8 (full radius) (302) H GHIC-70 DCONMS Boring Bars for Internal Grooving and Turning OAW Blades, DMIN=70 mm HF OAL Designation H DCONMS OAL HF OAW GHIC 40-70 26.0 40.00 260.00 18.0 53.0 SR M6X16 DIN912 HW 5.0 GHIC 50-70 26.0 50.00 300.00 23.0 53.0 SR M6X16 DIN912 HW 5.0 • For both right and left hand applications For tools, see pages: CGHN 26-M (356) • TGHN 26-M (354) 355

Каталог Iscar монолитные концевые фрезы и система multi-master

Каталог Iscar монолитные концевые фрезы и система multi-master Каталог Iscar сверла ружейные и для глубокого сверления 2022

Каталог Iscar сверла ружейные и для глубокого сверления 2022 Каталог Iscar токарные державки ISO 2022

Каталог Iscar токарные державки ISO 2022 Каталог Iscar инструмент для обработки алюминиевых колёс

Каталог Iscar инструмент для обработки алюминиевых колёс Каталог Iscar инструментальная оснастка 2022

Каталог Iscar инструментальная оснастка 2022