Каталог Iscar дисковые фрезы и фрезерные пластины 2022 - страница 228

Навигация

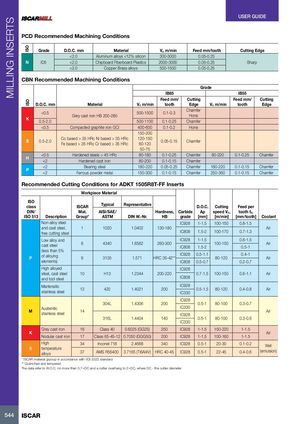

MILLING INSERTS ISOISO USER GUIDE PCD Recommended Machining Conditions Grade D.O.C. mm Material Vc m/min Feed mm/tooth Cutting Edge <2.0 Aluminum alloys <12% silicon 300-3000 0.05-0.25 N ID5 <2.0 Chipboard Fiberboard Plastics 2000-3000 0.05-0.25 Sharp <2.0 Copper Brass alloys 500-1500 0.05-0.25 CBN Recommended Machining Conditions Grade IB85 IB55 Feed mm/ Cutting Feed mm/ Cutting D.O.C. mm Material Vc m/min tooth Edge Vc m/min tooth Edge <0.5K0.5-2.0 Grey cast iron HB 200-280 500-1500 0.1-0.3 ChamferHone500-11000.1-0.25Chamfer <0.5 Compacted graphite iron GCI 400-600 0.1-0.2 Hone 150-200 S 0.5-2.0 Co based > 35 HRc Ni based > 35 HRcFe based > 35 HRc Cr based > 35 HRc120-15060-1200.05-0.15Chamfer 50-75 H <0.5<2 Hardened steels > 45 HRc 80-180 0.1-0.25 Chamfer 80-220 0.1-0.25 ChamferHardened cast iron80-2000.1-0.15Chamfer P <2<2 Bearing steel 180-220 0.05-0.25 Chamfer 180-220 0.1-0.15 ChamferFerrous powder metal150-3000.1-0.15Chamfer250-3600.1-0.15Chamfer Recommended Cutting Conditions for ADKT 1505R8T-FF Inserts Workpiece Material ISOclass ISCAR Typical Representative D.O.C. Cutting Feed per DIN/ Mat. AISI/SAE/ Hardness, Carbide Ap speed Vc, tooth fz, ISO 513 Description Group* ASTM DIN W.-Nr. HB grade [mm] [m/min] [mm/tooth] Coolant Non-alloy steel IC928 1-1.5 100-150 0.8-1.5 and cast steel, 1 1020 1.0402 130-180 Air free cutting steel IC808 1.5-2 100-170 0.7-1.3 Low alloy and IC928 1-1.5 0.8-1.5 cast steel 8 4340 1.6582 260-300 100-150 AirIC8081.5-20.5-1 (less than 5% P of alloying IC928 0.5-1.1 0.4-1931351.571HRC 35-42**80-120Air elements) IC808 0.5-0.7 0.2-0.7 High alloyed IC928 steel, cast steel 10 H13 1.2344 200-220 0.7-1.5 100-150 0.6-1.1 Air and tool steel IC808 Martensiticstainless steel12 420 IC9281.4021200 0.5-1.5 80-120 0.4-0.8 AirIC330 IC928 304L 1.4306 200 0.5-1 80-100 0.3-0.7 M Austeniticstainless steel14 IC330 AirIC928 316L 1.4404 140 0.5-1 80-100 0.3-0.6 IC330 Grey cast iron 16 Class 40 0.6025 (GG25) 250 IC928 1-1.5 150-220 1-1.5 K Air Nodular cast iron 17 Class 65-45-12 0.7050 (GGG50) 200 IC928 1-1.5 100-160 1-1.5 HighStemperaturealloys 34 Inconel 718 2.4668 340 IC928 0.5-1 20-30 0.1-0.2 Wet37AMS R564003.7165 (Ti6Al4V)HRC 40-45IC9280.5-122-450.4-0.6(emulsion) * ISCAR material grpoup in accordance with VDI 3323 standard ** Quenched and tempered The data refer to W.O.C. no more than 0.7×DC and a cutter overhang to 2×DC, where DC - the cutter diameter 544 ISCAR

Каталог Iscar крепление инструмента

Каталог Iscar крепление инструмента Каталог Iscar инструмент для обработки отверстий

Каталог Iscar инструмент для обработки отверстий Каталог Iscar резьбонарезные фрезы

Каталог Iscar резьбонарезные фрезы Каталог Iscar инструмента для сверления

Каталог Iscar инструмента для сверления Каталог Iscar решения для глубокого сверления

Каталог Iscar решения для глубокого сверления