Общий каталог Harlingen 2024 - страница 164

Навигация

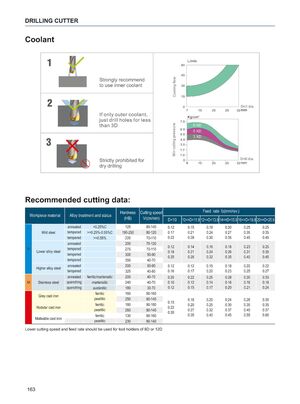

DRILLING CUTTER Coolant 1 Strongly recommend to use inner coolant If only outer coolant , just drill holes for less than 3 D 3 Strictly prohibited for dry drilling Recommended cutting data: Workpiece material P M Mild steel annealed tempered tempered Lower alloy steel annealed tempered tempered tempered Higher alloy steel annealed tempered Stainless steel annealed quenching quenching Grey cast iron K Alloy treatment and status Nodular cast iron Malleable cast iron <0.25%C >=0.25%-0.55%C >=0.55% ferritic/martensitic martensitic austenitic ferritic pearlitic ferritic pearlitic ferritic pearlitic Hardness (HB) Cutting speed Vc(m/min) 125 190-250 220 200 275 300 350 200 325 200 240 180 160 250 180 260 130 230 80-140 80-120 70-110 70-120 70-110 50-90 40-70 50-90 40-80 40-70 40-70 30-70 90-160 80-140 90-180 80-140 90-160 80-140 Lower cutting speed and feed rate should be used for tool holders of 8D or 12D 163 Feed rate fz(mm/rev.) D<10 10<=D<11.9 12<=D<13.9 14<=D<15.9 16<=D<19.9 20<=D<25.9 0.12 0.17 0.22 0.15 0.21 0.28 0.18 0.24 0.30 0.20 0.27 0.35 0.25 0.35 0.45 0.25 0.35 0.45 0.12 0.18 0.25 0.14 0.21 0.28 0.16 0.24 0.32 0.18 0.26 0.35 0.23 0.31 0.40 0.25 0.35 0.45 0.12 0.16 0.12 0.17 0.15 0.20 0.18 0.23 0.20 0.25 0.22 0.27 0.20 0.10 0.12 0.22 0.12 0.15 0.25 0.14 0.17 0.28 0.16 0.20 0.30 0.16 0.21 0.33 0.18 0.24 0.15 0.22 0.30 0.18 0.20 0.27 0.35 0.20 0.25 0.32 0.40 0.24 0.30 0.37 0.45 0.26 0.35 0.45 0.55 0.30 0.35 0.37 0.60

Каталог Harlingen самоцентрирующиеся тиски и системы нулевого базирования

Каталог Harlingen самоцентрирующиеся тиски и системы нулевого базирования Каталог Harlingen системы нулевого базирования

Каталог Harlingen системы нулевого базирования Каталог Harlingen инструмент для пресс-форм 2024

Каталог Harlingen инструмент для пресс-форм 2024 Каталог Harlingen PSC-оправки (CAPTO совместимые)

Каталог Harlingen PSC-оправки (CAPTO совместимые) Каталог Harlingen статические держатели режущих инструментов блочного типа

Каталог Harlingen статические держатели режущих инструментов блочного типа