Общий каталог FANAR 2021 - страница 3

Навигация

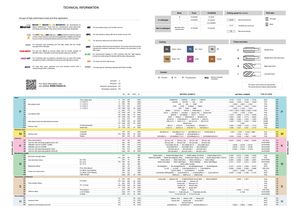

TECHNICAL INFORMATION Mark Price Availability Cutting speed Vc (m/min) Hole type in pricelist on stock Groups of high performance tools and their application: Throught In catalogue in pricelist on request 10-15 Recommended tool - - not available Linia MASTERTAP, MASTERMILL and MASTERDRILL are characterized by Blind10-15Permitted use of the tool MASTER highest performance. These tools are manufactured using state-of-art. GG For processing of grey and nodular cast iron.technology and materials. They can be used in a wide range of materials. standard indexNot in catalogue on request on requestspecial index Manual processing Linia The 800 Taps, X-MILL Mills and X-DRILL Drill Bits contain the highest GAL For cast aluminum alloys with the Si content of max 12%. number of tool variants to suiit almost anyapplication. Multifunctional tools for use on both conventional machine tools and modern CNC machines. For aluminum alloys and non ferrous metals. Coating Flutes execution 800 For structural, free machining and low alloy steels with the tensile strength of Rm ≤ 800 Mpa. HRC For materials, which have been hardened. The number next to the symbol indicates the maximum hardness of the material to be processed, in the FAN-1200 For tool and difficult to process steels with the tensile strength of HRC scale. HL TiAIN + WC/C TC TiN + TiCN TB TiB2 C Straight flutes 800 MPa ≤ Rm ≤ 1200 MPa, and for heat treated steels up to 38 HRC. S-NC For synchronized tapping on CNC machines with the "rigid tapping" function for a wide range of materials with the high cutting speeds. 1400-HT For machining hard and abrasive materials such as steel with tensilestrenght from 1200 to 1400 Mpa and aluminum with high silicon content. TN2 TiAIN + TiN AT AITiN TS TiAISiN B Straight flutes with spiral point Ms For brass and short chip bronze. INOX For high alloy steel, stainless and acid resistant steels with a WGN Forming taps for machining materials with limited ductility. R Right spiral flutes tensile strength of Rm ≤ 1000 Mpa. Coolant L Left spiral flutes E Emulsion O Oil P Threading paste MQL Minimum Quantity Lubrication Annealed A For more information visit Tempered QT The speed values below are approximate. our website WWW.FANAR.PL Hardened and tempered HT The speed should be adjust experimentally. Precipitation hardened PH Rm HB HRC kc MATERIAL EXAMPLE MATERIAL NUMBER TYPE OF CHIPS Steel Stal P1 Free cutting steel A 750 220 2500 11SMnPb30 / 10SPb20 / 35S20 / 11SMn37 1.0718 / 1.0722P1/ 1.0726 / 1.0736 short P1 P2 C ≤ 0,55 % A 650 190 - 2500 S235JR / S275JR / C22 / C45 1.0038 / 1.0044P2/ 1.0402 / 1.0503 long P2 P3 Non-alloyed steel C > 0,55 % A 650 190 - 2500 C55 / C60 / C60E 1.0535 / 1P.03601 / 1.1221 long P3 P4 C ≤ 0,55 % QT 700 210 - 2500 C25E / C53G / G18Mo5 / 16Mo5 1.1158 / 1.1213 P4/ 1.5422 / 1.5423 long P4 P5 C > 0,55 % QT 1000 300 32 2600 C55 / C55E / C60E 1.0535 / 1P.15203 / 1.1221 long P5 P6 A 600 175 - 2300 36Mn5 / 107CrV3 / 100Cr6 / 20NiCrMo2-2 / 41Cr4 1.1167 / 1.2210 / 1.P36505 / 1.6523 / 1.7035 long P6 P P7 QT 1000 300 32 2600 34Cr4 / 25CrMo4 / 42CrMo4 / Weldox 700 / Weldox 900 1.7033 / 1P.77218 / 1.7225 long P7 P Low-alloyed steel P8 QT 1200 380 41 3000 36NiCr6 / 34CrNiMo6 / 55Cr3 / 51CrV4 1.5710 / 1.6582P8/ 1.7176 / 1.8159 long P8 P9 QT 1400 420 45 3600 55Si7 / 60SiCr7 / 55NiCrMoV6 / 40CrMoV13-9 1.0904 / 1.0961P9/ 1.2713 / 1.8523 long P9 P10 A 700 210 - 2500 X210Cr12 / X100CrMoV5-1 / HS6-5-2-5 / HS6-5-2 1.2080 / 1.2363P1/0 1.3243 / 1.3343 middle P10 P11 High-alloyed steel and high-alloyed tool steel A 1000 300 32 2600 HS6-5-2-5 / HS18-1-2-5 / HS 10-2-5-8 / HS 6-5-3-8 1.3243 / 1.3255P1/1 1.3253 / 1.3294 middle P11 P12 HT 1400 420 45 3600 X30WCrV9-3 1P.215281 middle P12 P13 Ferritic/martensitic A 700 210 - 3200 X6Cr13 / X12Cr13 / X14CrMoS17 / X6CrMo17-1 1.4000 / 1.4006P1/3 1.4104 / 1.4113 long P13 Stainless steel P14 Martensitic QT 1100 330 34 3200 X12Cr13 / GX20Cr14 / X19CrNi17-2 / X45CrSi9-3-1 1.4006 / 1.4027P1/4 1.4057 / 1.4718 long P14 Stainless steel M1 Austenitic 700 210 - 3200 X5CrNi18-10 / X5CrNiMo17-12-2 / X2CrNiMo18-14-3 / X12NiCrSi36-16 1.4301 / 1.4401 / 1.4435 ,1.4864 long M1 M M2 Stainless steel Austenitic PH 1000 300 32 3200 X9CrNi18-8 / X53CrMnNiN21-9 1.4310 / 1.4871 long M2 M M3 Duplex 800 240 23 4000 X2CrNiN23-4 / X2CrNiMoN17-13-3 / X2CrNiMoN22-5-3 / X2CrNiMoCuN25-6-3 1.4362 / 1.4429 / 1.4462 / 1.4507 long M3 Cast iron K1 Grey cast iron(GJL) 400 120 - 1600 EN-GJL-100 / EN-GJL-200 / EN-GJL-300 / EN-GJL-400 0.6010 / 0.6020 / 0.6030 / 0.6040 very short K1 K2 Cast iron with vermicular graphite (GJV) CGI 550 160 - 2500 EN-GJV-300 / EN-GJV-400 / EN-GJV-500 / EN-GJV-550 - short/middle K2 K3KK4 Malleable cast iron (GJMW / GJMB)Malleable cast iron (GJMB) 500 150 - 2700800240-2700 EN-GJMW-300-26 / EN-GJMB-350-10 / EN-GJMB-450-6EN-GJMB-550-4/EN-GJMB-700-2/EN-GJMB-800-1 0.8035 / 0.8135 / 0.81450.8155/0.8170/0.8180short/middle K3short/middleK4K K5 Cast iron with spheroidal graphite (GJS) 700 210 - 2400 EN-GJS-400-15 / EN-GJS-500-7 / EN-GJS-700-2 0.7040 / 0.7050 / 0.7070 short/middle K5 K6 Cast iron with spheroidal graphite (GJS) ADI 1400 420 45 3600 EN-GJS-800-8 / EN-GJS-1200-2 / EN-GJS-1400-1 - short/middle K6 Non-ferrous metals N1 200 - - 680 ENAW-Al99.5 / ENAW-AlSi1MgMn (PA4) / ENAW-AlMg0.7Si (PA38) / ENAW-AlMg3 (PA11) 3.0255 / 3.2315 / 3.3206 / 3.3535 long N1 Aluminium wrought alloys N2 PH 500 152 - 680 ENAW-AlCu6BiPb / ENAW-AlCu4MgSi(A) (PA6) / ENAW-AlZn5.5MgCu (Pa9) / ENAW-AlMg4.5Mn0.7 (PA13) 3.1655 / 3.1325 / 3.4365 / 3.3547 long N2 N3 Cast aluminium alloys Si ≤ 12% 250 75 - 680 ENAC-AlSi12 / ENAC-AlSi12(Fe) / ENAC-AlSi12(Cu) / ENAC-AlMg5 3.2581 / 3.2582 / 3.2583 / 3.3561 short/middle N3 N4 Si ≤ 12% PH 300 90 - 680 ENAC-AlCu4MgTi / ENAC-AlSi7Mg0.3 / ENAC-AlSi9Mg / ENAC-AlSi10Mg(a) 3.1371 / 3.2371 / 3.2373 / 3.2381 short/middle N4 N N5 Si> 12 % 450 130 - 680 ENAC-AlSi17Cu4Mg - short N5 N N6 Magnesium alloys 250 70 - 750 EN-MAMgMn1 / EN-MCMgRE3Zn2Zr / EN-MCMgRE2Ag2Zr / EN-MCMgAl4Si 3.5101 / 3.5103 / 3.3506 / 3.5470 short N6 N7 Pure, Non-alloyed 350 100 - 1100 Cu-OF / Cu-DHP / CuZn35Mn2Al1Fe1-C / CuAl10Ni5Fe4 2.0040 / 2.0090 / 2.0592 / 2.0966 extra long N7 N8 Cu-alloys, long-chipping 600 180 - 1900 CuZn37 (M63) / CuAl10Ni5Fe4 / CuSn8P 2.0321 / 2.0966 / 2.1030 long N8 Copper and copper alloys N9 Cu-alloys, short-chipping 400 120 - 1900 CuZn40Pb2 (M58)(MO58) / CuSn7Zn4Pb7-C / CuSn5Zn5Pb5-C / CuSn10Pb10-C 2.0402 / 2.1090 / 2.1096 / 2.1176 short N9 N10 High-strength, 1000 300 32 1400 AMPCO 8 / AMPCO 21 / AMPCO M4 - long N10 Superalloys and titanium S1 A 675 200 - 4000 Incoloy 909 / Multimet 155 / X10NiCrAlTi3220 (Incoly 800) / X40CoCrNi2020 1.4876 / 1.4977 long S1 S2 Fe-based PH 950 280 29 4000 Incoloy A-286 / Unitemp 212 - long S2 S3 Heat-resistant alloys A 850 250 25 4000 Incoloy 864 / Nimocast 713 - long S3 S S4S5 Ni / Co base PH 1200 350 38 4000 Inconel 718 / Nimonic 80AC1100320344000GMR 235*/Jessop G81* -- long S4longS5S S6 Pure titanium 675 200 - 4000 Ti 99.8 / TiCu2 3.7025 / 3.7124 extra long S6 S7 Titanium alloys α and β alloys 1250 375 40 4000 Ti-6Al-4V / Ti-6Al-2Mo-2Cr / Ti-6Al-6Mo-4Zr-2Sn 3.7165 short/middle S7 S8 β alloys 1400 410 44 4000 Ti-10V-2Fe-3Al / Ti-13V-11Cr-3Al - short/middle S8 Hard materials H1 HT 50 4100 Weldox 1100 / Weldox 1300 / Hardox 500 - short H1 H2HH3 Hardened steel HT 55 4700 Hardox 550 / Hardox 600 / Armox 600 THT605000Hardox Extreme -- shortshort H2H3 H H4 Hardened and tempered cast iron HT 55 4700 GX260NiCr42 / GX330NiCr42 / GX300CrMoNi15-2-1 0.9620 / 0.9625 / 0.9640 short H4 MATERIAL GROUP MATERIAL GROUP

Общий каталог FANAR 2018

Общий каталог FANAR 2018 Каталог FANAR цельные твердосплавные фрезы

Каталог FANAR цельные твердосплавные фрезы