Общий каталог Dijet 2018 - страница 525

Навигация

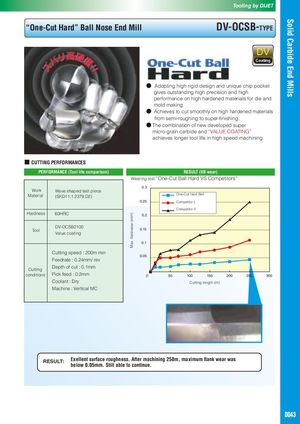

Solid Carbide End Mills Tooling by DIJET “One-Cut Hard” Ball Nose End Mill DV-OCSB-TYPE ● Adopting high rigid design and unique chip pocket gives outstanding high precision and high performance on high hardened materials for die and mold making. ● Achieves to cut smoothly on high hardened materials from semi-roughing to super-finishing. ● The combination of new developed super micro-grain carbide and “VALUE COATING” achieves longer tool life in high speed machining. ■ CUTTING PERFORMANCES PERFORMANCE (Tool life comparison) RESULT (VB wear) Wearing test “One-Cut Ball Hard VS Competitors“ 0.3 Work Wave shaped test piece Material (SKD11,1.2379,D2) One-Cut Hard Ball 0.25 Competitor L Competitor V Hardness 60HRC 0.2 DV-OCSB2100ToolValue coating 0.15 0.1 Cutting speed : 200m min 0.05 Feedrate : 0.24mm/ rev Cutting Depth of cut : 0.1mm conditions Pick feed : 0.2mm 0 50 100 150 200 250 300 Coolant : Dry Cutting length (m) Machine : Vertical MC RESuLT: Exellent surface roughness. After machining 250m, maximum flank wear wasbelow 0.05mm. Still able to continue. D043 Max. flankwear (mm)

Общий каталог Dijet 2012 на русском

Общий каталог Dijet 2012 на русском