Общий каталог Dijet 2018 - страница 470

Навигация

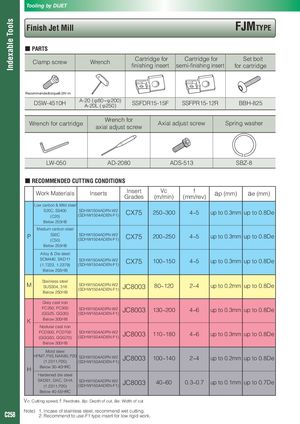

Indexable Tools Tooling by DIJET Finish Jet Mill FJMTYPE ■ PARTS Clamp screw Wrench Cartridge for Cartridge for Set boltfinishing insertsemi-finishing insertfor cartridge Recommendedtorque6.0N・m DSW-4510H A-20 (ϕ80~ϕ200)A-20L (ϕ250)SSFDR15-15F SSFPR15-12R BBH-825 Wrench for cartridge Wrench foraxial adjust screw Axial adjust screw Spring washer LW-050 AD-2080 ADS-513 SBZ-8 ■ RECOMMENDED CUTTING CONDITIONS Work Materials Inserts InsertGrades Vc(m/min) f(mm/rev)ap (mm) ae (mm) Low carbon & Mild steel S20C, SS400(C20) SDHW1504ADFN-W2(SDHW1504ADEN-F1)CX75 250~300 4~5 up to 0.3mm up to 0.8De Below 255HB Medium carbon steel P S50C(C50) SDHW1504ADFN-W2(SDHW1504ADEN-F1)CX75 200~250 4~5 up to 0.3mm up to 0.8De Below 255HB Alloy & Die steel SCM440, SKD11 SDHW1504ADFN-W2 CX75 100~150 4~5 up to 0.3mm up to 0.8De (1.7223, 1.2379) (SDHW1504ADEN-F1) Below 255HB Stainless steel M SUS304, 316 SDHW1504ADFN-W2(SDHW1504ADEN-F1)JC8003 80~120 2~4 up to 0.2mm up to 0.8De Below 250HB Grey cast iron FC250, FC300 SDHW1504ADFN-W2 JC8003 130~200 4~6 up to 0.3mm up to 0.8De (GG25, GG30) (SDHW1504ADEN-F1) K Below 300HB Nodular cast iron FCD500, FCD700(GGG50, GGG70)SDHW1504ADFN-W2(SDHW1504ADEN-F1)JC8003110~180 4~6 up to 0.3mm up to 0.8De Below 300HB Mold steel HPM7, PX5, NAK80, P20 SDHW1504ADFN-W2(1.2311,P20)(SDHW1504ADEN-F1)JC8003100~1402~4 up to 0.2mm up to 0.8De H Below 30-40HRC Hardened die steel SKD61, DAC, DHA(1.2311,P20)SDHW1504ADFN-W2(SDHW1504ADEN-F1)JC800340~60 0.3~0.7 up to 0.1mm up to 0.7De Below 40-55HRC Vc: Cutting speed, f: Feedrate, ap: Depth of cut, ae: Width of cut C258 Note) 1. Incase of stainless steel, recommend wet cutting.2. Recommend to use-F1 type insert for low rigid work.

Общий каталог Dijet 2012 на русском

Общий каталог Dijet 2012 на русском