Общий каталог Dijet 2018 - страница 403

Навигация

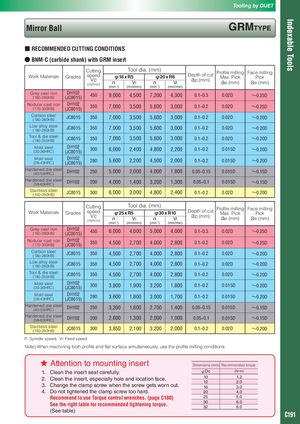

Indexable Tools Tooling by DIJET Mirror Ball GRMTyPE ■ RECOMMENDED CUTTING CONDITIONS ● BNM-C (carbide shank) with GRM insert CuttingWork MaterialsGradesspeedVc(m/min)Tool dia. (mm)φ16 x R5φ20 x R6nVfnVfDepth of cutap (mm)Profile millingMax. Pickae (mm)Face millingPickae (mm)(min-1)(mm/min)(min-1)(mm/min) Grey cast iron(160-260HB)DH102(JC8015)450 9,000 4,500 7,200 4,300 0.1−0.3 0.02D ~0.25D Nodular cast iron DH102(170-300HB)(JC8015)3507,000 3,500 5,600 3,000 0.1−0.2 0.02D ~0.25D Carbon steel(180-280HB)JC8015 350 7,000 3,500 5,600 3,000 0.1−0.2 0.02D ~0.20D Low alloy steel(180-280HB)JC8015350 7,000 3,500 5,600 3,000 0.1−0.2 0.02D ~0.20D Tool & die steel(180-255HB)JC8015350 7,000 3,500 5,600 3,000 0.1−0.2 0.02D ~0.20D Mold steel(30-36HRC)DH102(JC8015)300 6,000 2,400 4,800 2,200 0.1−0.2 0.015D ~0.20D Mold steel(38-43HRC)DH102(JC8015)280 5,600 2,200 4,500 2,000 0.1−0.2 0.015D ~0.20D Hardened die steel(40-55HRC)DH102 250 5,000 2,000 4,000 1,800 0.05−0.15 0.015D ~0.15D Hardened die steel(56-63HRC)DH102 200 4,000 1,400 3,200 1,300 0.05−0.1 0.015D ~0.15D Stainless steel(150-250HB)JC8015300 6,000 3,000 4,800 2,400 0.1−0.2 0.02D ~0.20D CuttingWork MaterialsGradesspeedVc(m/min)Tool dia. (mm)φ25 x R5φ30 x R10nVfnVfDepth of cutap (mm)Profile millingMax. Pickae (mm)Face millingPickae (mm)(min-1)(mm/min)(min-1)(mm/min) Grey cast iron(160-260HB)DH102(JC8015)450 6,000 4,000 5,000 4,000 0.1−0.3 0.02D ~0.25D Nodular cast iron DH102(170-300HB)(JC8015)3504,500 2,700 4,000 2,800 0.1−0.2 0.02D ~0.25D Carbon steel(180-280HB)JC8015 350 4,500 2,700 4,000 2,800 0.1−0.2 0.02D ~0.20D Low alloy steel(180-280HB)JC8015350 4,500 2,700 4,000 2,800 0.1−0.2 0.02D ~0.20D Tool & die steel(180-255HB)JC8015350 4,500 2,700 4,000 2,800 0.1−0.2 0.02D ~0.20D Mold steel(30-36HRC)DH102(JC8015)300 3,800 1,900 3,200 1,800 0.1−0.2 0.015D ~0.20D Mold steel(38-43HRC)DH102(JC8015)280 3,600 1,800 3,000 1,700 0.1−0.2 0.015D ~0.20D Hardened die steel(40-55HRC)DH102 250 3,200 1,600 2,700 1,400 0.05−0.15 0.015D ~0.15D Hardened die steel(56-63HRC)DH102 200 2,600 1,300 2,000 1,000 0.05−0.1 0.015D ~0.15D Stainless steel(150-250HB)JC8015300 3,850 2,100 3,200 2,000 0.1−0.2 0.02D ~0.20D n: Spindle speed, Vf: Feed speed Note) When machining both profile and flat surface simultaneously, use the profile milling conditions. ★ Attention to mounting insert Dimensions (mm) Recommended torque 1. Clean the insert seat carefully. φDc (N・m) 2. Clean the insert, especially hole and location face. 10 1.2 3. Change the clamp screw when the screw gets worn out. 1216 2.03.0 4. Do not tightened the clamp screw too hard. 20 4.0 Recommend to use Torque control wrenches. (page C180) 25 5.0 See the right table for recommended tightening torque. 30 6.0326.0 (See table) C191

Общий каталог Dijet 2012 на русском

Общий каталог Dijet 2012 на русском