Общий каталог Dijet 2018 - страница 288

Навигация

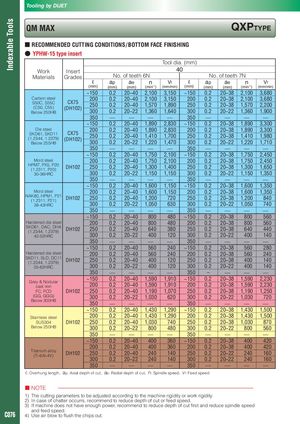

Indexable Tools Tooling by DIJET QM MAX QXPTyPE ■ RECOMMENDED CUTTING CONDITIONS / BOTTOM FACE FINISHING ● YPHW-15 type insert Tool dia. (mm) Work Insert 40 Materials Grades No. of teeth 6N No. of teeth 7N ℓ ap ae n Vf ℓ ap ae n Vf (mm) (mm) (mm) (min-1) (mm/min) (mm) (mm) (mm) (min-1) (mm/min) ~150 0.2 20~40 2,100 3,150 ~150 0.2 20~38 2,100 3,680 Carbon steelS50C, S55C(C50, C55)Below 250HBCX75(DH102)2002503000.220~402,1003,1500.220~401,5701,8900.220~221,3601,6402000.220~382,1003,6802500.220~381,5702,2003000.220~221,3601,900 350 — — — — 350 — — — — ~150 0.2 20~40 1,890 2,830 ~150 0.2 20~38 1,890 3,300 Die steelSKD61, SKD11CX75(1.2344, 1.2379)(DH102)Below 255HB2002503000.220~401,8902,8300.220~401,4101,7000.220~221,2201,4702000.220~381,8903,3002500.220~381,4101,9803000.220~221,2201,710 350 — — — — 350 — — — — ~150 0.2 20~40 1,750 2,100 ~150 0.2 20~38 1,750 2,450 Mold steel 200 0.2 20~40 1,750 2,100 200 0.2 20~38 1,750 2,450 HPM7, PX5, P20(1.2311, P20)DH102250 0.2 20~40 1,300 1,400 250 0.2 20~38 1,300 1,650 30-36HRC 300 0.2 20~22 1,150 1,150 300 0.2 20~22 1,150 1,350 350 — — — — 350 — — — — ~150 0.2 20~40 1,600 1,150 ~150 0.2 20~38 1,600 1,350 Mold steel 200 0.2 20~40 1,600 1,150 200 0.2 20~38 1,600 1,350 NAK80, HPM1, P21(1.2311, P21)DH102250 0.2 20~40 1,200 720 250 0.2 20~38 1,200 840 38-43HRC 300 0.2 20~22 1,050 630 300 0.2 20~22 1,050 740 350 — — — — 350 — — — — ~150 0.2 20~40 800 480 ~150 0.2 20~38 800 560 Hardened die steel 200 0.2 20~40 800 480 200 0.2 20~38 800 560 SKD61, DAC, DHA(1.2344, 1.2379)DH10242-52HRC2503000.220~40 6400.220~22400380120250 0.2 20~38 6403000.220~22400440140 350 — — — — 350 — — — — ~150 0.2 20~40 560 240 ~150 0.2 20~38 560 280 Hardened die steel 200 0.2 20~40 560 240 200 0.2 20~38 560 240 SKD11, SLD, DC11(1.2344, 1.2379)DH10255-62HRC2503000.220~40 4000.220~22400120120250 0.2 20~38 4003000.220~22400140140 350 — — — — 350 – — — — Grey & Nodularcast iron ~150 0.2 20~40 1,590 1,910 ~150 0.2 20~38 1,590 2,2302000.220~401,5901,9102000.220~381,5902,230 FC, FCD DH102 250 0.2 20~40 1,190 1,070 250 0.2 20~38 1,190 1,250 (GG, GGG) 300 0.2 20~22 1,030 620 300 0.2 20~22 1,030 720 Below 300HB 350 — — — — 350 — — — — ~150 0.2 20~40 1,430 1,290 ~150 0.2 20~38 1,430 1,500 Stainless steel 200 0.2 20~40 1,430 1,290 200 0.2 20~38 1,430 1,500 SUS304 DH102 250 0.2 20~40 1,030 740 250 0.2 20~38 1,030 870 Below 250HB 300 0.2 20~22 800 480 300 0.2 20~22 800 560 350 — — — — 350 — — — — ~150 0.2 20~40 400 360 ~150 0.2 20~38 400 420 200 0.2 20~40 400 360 200 0.2 20~38 400 420 Titanium alloy(Ti-6Al-4V)DH102250300 0.2 20~40 2400.220~22240140140250 0.2 20~22 2403000.220~22240160160 350 — — — — 350 — — — — ℓ: Overhung length, ap: Axial depth of cut, ae: Radial depth of cut, n: Spindle speed, Vf: Feed speed ■ NOTE 1) The cutting parameters to be adjusted according to the machine rigidity or work rigidity. 2) In case of chatter occurrs, recommend to reduce depth of cut or feed speed. 3) If machine does not have enough power, recommend to reduce depth of cut first and reduce spindle speed C076 and feed speed.4)Use air blowto flushthe chipsout.

Общий каталог Dijet 2012 на русском

Общий каталог Dijet 2012 на русском