Общий каталог Dijet 2018 - страница 208

Навигация

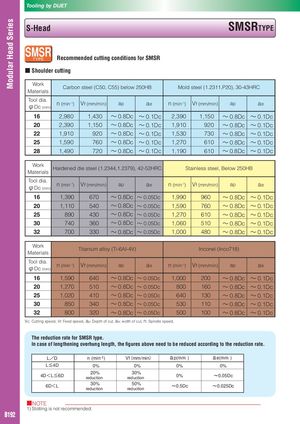

Modular Head Series Tooling by DIJET S-Head SMSRTYPE SMSR TY PE Recommended cutting conditions for SMSR ■ Shoulder cutting Work Carbon steel (C50, C55) below 250HB Mold steel (1.2311,P20), 30-43HRC Materials Tool dia.φDc (mm)n (min-1)Vf (mm/min) ap ae n (min-1) Vf (mm/min) ap ae 16 2,980 1,430 ~ 0.8Dc ~ 0.1Dc 2,390 1,150 ~ 0.8Dc ~ 0.1Dc 20 2,390 1,150 ~ 0.8Dc ~ 0.1Dc 1,910 920 ~ 0.8Dc ~ 0.1Dc 22 1,910 920 ~ 0.8Dc ~ 0.1Dc 1,530 730 ~ 0.8Dc ~ 0.1Dc 25 1,590 760 ~ 0.8Dc ~ 0.1Dc 1,270 610 ~ 0.8Dc ~ 0.1Dc 28 1,490 720 ~ 0.8Dc ~ 0.1Dc 1,190 610 ~ 0.8Dc ~ 0.1Dc Work Hardened die steel (1.2344,1.2379), 42-52HRC Stainless steel, Below 250HB Materials Tool dia.φDc (mm)n (min-1)Vf (mm/min) ap ae n (min-1) Vf (mm/min) ap ae 16 1,390 670 ~ 0.8Dc ~ 0.05Dc 1,990 960 ~ 0.8Dc ~ 0.1Dc 20 1,110 540 ~ 0.8Dc ~ 0.05Dc 1,590 760 ~ 0.8Dc ~ 0.1Dc 25 890 430 ~ 0.8Dc ~ 0.05Dc 1,270 610 ~ 0.8Dc ~ 0.1Dc 30 740 360 ~ 0.8Dc ~ 0.05Dc 1,060 510 ~ 0.8Dc ~ 0.1Dc 32 700 330 ~ 0.8Dc ~ 0.05Dc 1,000 480 ~ 0.8Dc ~ 0.1Dc WorkMaterials Titanium alloy (Ti-6AI-4V) Inconel (Inco718) Tool dia.φDc (mm)n (min-1)Vf (mm/min) ap ae n (min-1) Vf (mm/min) ap ae 16 1,590 640 ~ 0.8Dc ~ 0.05Dc 1,000 200 ~ 0.8Dc ~ 0.1Dc 20 1,270 510 ~ 0.8Dc ~ 0.05Dc 800 160 ~ 0.8Dc ~ 0.1Dc 25 1,020 410 ~ 0.8Dc ~ 0.05Dc 640 130 ~ 0.8Dc ~ 0.1Dc 30 850 340 ~ 0.8Dc ~ 0.05Dc 530 110 ~ 0.8Dc ~ 0.1Dc 32 800 320 ~ 0.8Dc ~ 0.05Dc 500 100 ~ 0.8Dc ~ 0.1Dc Vc: Cutting speed, Vf: Feed speed, ap: Depth of cut, ae: width of cut, n: Spindle speed, The reduction rate for SMSR type. In case of lengthening overhung length, the figures above need to be reduced according to the reduction rate. L/D n (min-1) Vf (mm/min) a p(mm ) a e(mm ) L≦4D 0% 0% 0% 0% 4D<L≦6D 20%reduction 30%reduction 0% ~0.05Dc 6D<L 30% 50%reductionreduction~0.5Dc ~0.025Dc ■NOTE 1) Slotting is not recommended. B192

Общий каталог Dijet 2012 на русском

Общий каталог Dijet 2012 на русском