Общий каталог Dijet 2018 - страница 197

Навигация

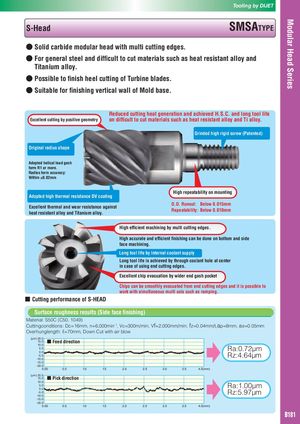

Modular Head Series Tooling by DIJET S-Head SMSATYPE ● Solid carbide modular head with multi cutting edges. ● For general steel and difficult to cut materials such as heat resistant alloy and Titanium alloy. ● Possible to finish heel cutting of Turbine blades. ● Suitable for finishing vertical wall of Mold base. Reduced cutting heat generation and achieved H.S.C. and long tool life Excellent cutting by positive geometry on difficult to cut materials such as heat resistant alloy and Ti alloy. Grinded high rigid screw (Patented) Original radius shape Adopted helical lead gash form R1 or more. Radius form accuracy: Within ±0.02mm High repeatability on mounting Adopted high thermal resistance DV coating Excellent thermal and wear resistance againstheat resistant alloy and Titanium alloy. O.D. Runout: Below 0.015mmRepeatability: Below 0.010mm High efficient machining by multi cutting edges. High accurate and efficient finishing can be done on bottom and side face machining. Long tool life by internal coolant supply Long tool life is achieved by through coolant hole at center in case of using end cutting edges. Excellent chip evacuation by wider end gash pocket Chips can be smoothly evacuated from end cutting edges and it is possible to work with simultaneous multi axis such as ramping. ■ Cutting performance of S-HEAD Surface roughness results (Side face finishing) Material: S50C (C50, 1049) Cuttingconditions: Dc=16mm, n=6,000min-1, Vc=300m/min, Vf=2,000mm/min, fz=0.04mm/t,ap=8mm, ae=0.05mm Overhunglength: ℓ=70mm, Down Cut with air blow (μm) 20.0 15.0 ■ Feed direction 10.05.0 Ra:0.72μm 0.0-5.0 Rz:4.64μm -10.0 -15.0 -20.0 0.00 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0(mm) (μm) 20.0 15.0 ■ Pick direction 10.05.0 Ra:1.00μm 0.0-5.0 Rz:5.97μm -10.0 -15.0 -20.0 0.00 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0(mm) B181

Общий каталог Dijet 2012 на русском

Общий каталог Dijet 2012 на русском