Общий каталог Dijet 2018 - страница 184

Навигация

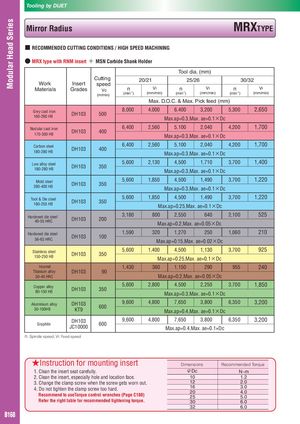

Modular Head Series Tooling by DIJET Mirror Radius MRXTYPE ■ RECOMMENDED CUTTING CONDITIONS / HIGH SPEED MACHINING ● MRX type with RNM insert + MSN Carbide Shank Holder Tool dia. (mm) CuttingWorkInsertspeed 20/21 25/26 30/32 Materials Grades Vc(m/min) n Vf n(min-1)(mm/min)(min-1)Vf(mm/min)n Vf(min-1)(mm/min) Max. D.O.C. & Max. Pick feed (mm) Grey cast iron160-260 HB 8,000 4,000 6,400 3,200 5,300 2,650DH103500Max.ap=0.3,Max. ae=0.1×Dc Nodular cast iron170-300 HBDH103 400 6,400 2,560 5,100 2,040 4,200 1,700Max.ap=0.3,Max. ae=0.1×Dc Carbon steel180-280 HB 6,400 2,560 5,100 2,040 4,200 1,700DH103400Max.ap=0.3,Max. ae=0.1×Dc Low alloy steel180-280 HBDH103 350 5,600 2,130 4,500 1,710 3,700 1,400Max.ap=0.3,Max. ae=0.1×Dc Mold steel280-400 HB 5,600 1,850 4,500 1,490 3,700 1,220DH103350Max.ap=0.3,Max. ae=0.1×Dc Tool & Die steel180-255 HBDH103 350 5,600 1,850 4,500 1,490 3,700 1,220Max.ap=0.25,Max. ae=0.1×Dc Hardened die steel40-55 HRCDH103 200 3,180 800 2,550 640 2,100Max.ap=0.2,Max. ae=0.05×Dc525 Hardened die steel56-63 HRCDH103 100 1,590 320 1,270 250 1,060Max.ap=0.15,Max. ae=0.02×Dc210 Stainless steel150-250 HB 5,600 1,400 4,500 1,130 3,700DH103350Max.ap=0.25,Max. ae=0.1×Dc925 Inconel 1,430 360 1,150 290 955 240 Titanium alloy DH103 9030-40 HRC Max.ap=0.2,Max. ae=0.05×Dc Copper alloy80-150 HB 5,600 2,800 4,500 2,250 3,700 1,850DH103350Max.ap=0.3,Max. ae=0.1×Dc Aluminium alloy30-100HBDH103KT9 600 9,600 4,800 7,650 3,800 6,350 3,200Max.ap=0.4,Max. ae=0.1×Dc Graphite DH103JC10000 600 9,600 4,800 7,650 3,800 6,350 3,200Max.ap=0.4,Max. ae=0.1×Dc n: Spindle speed, Vf: Feed speed ★Instruction for mounting insert Dimensions Recommended Torque 1. Clean the insert seat carefully. φDc N~m 2. Clean the insert, especially hole and location face. 10 1. 2 3. Change the clamp screw when the screw gets worn out. 12 2.0 4. Do not tighten the clamp screw too hard.Recommend to useTorque control wrenches (Page C180)162025 3.04.05.0 Refer the right table for recommended tightening torque. 30 6.0 32 6.0 B168

Общий каталог Dijet 2012 на русском

Общий каталог Dijet 2012 на русском