Общий каталог Dijet 2018 - страница 131

Навигация

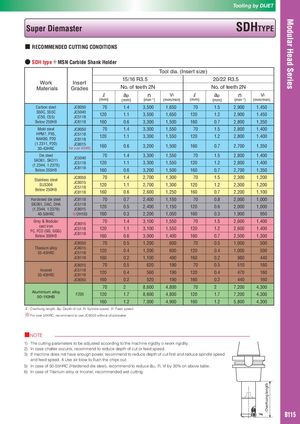

Tooling by DIJET Super Diemaster SDHTYPE ■ RECOMMENDED CUTTING CONDITIONS ● SDH type+MSN Carbide Shank Holder Tool dia. (Insert size) Work Insert 15/16 R3.5 20/22 R3.5 Materials Grades No. of teeth 2N No. of teeth 2N ℓ ap n Vf ℓ ap n Vf (mm) (mm) (min-1) (mm/min) (mm) (mm) (min-1) (mm/min) Carbon steel JC8050 70 1.4 3,500 1,650 70 1.5 2,900 1,450 S50C, S55C(C50, C55) JC5040JC5118 120 1.1 3,500 1,650 120 1.2 2,900 1,450 Below 250HB JC8118 160 0.6 3,300 1,500 160 0.7 2,800 1,350 Mold steel JC8050 70 1.4 3,300 1,550 70 1.5 2,800 1,400 HPM7, PX5,NAK80, P20 JC5118JC8118 120 1.1 3,300 1,550 120 1.2 2,800 1,400 (1.2311, P20)30-43HRC JC8015For over 40HRC160 0.6 3,200 1,500 160 0.7 2,700 1,350 Die steelSKD61, SKD11(1.2344, 1.2379)Below 255HBJC5040JC5118JC8118701201601.43,3001,550 701.13,3001,5501200.63,2001,5001601.52,8001,4001.22,8001,4000.72,7001,350 Stainless steelSUS304Below 250HBJC8050 70JC8015JC5118120JC81181601.42,700 1,300 701.12,7001,3001200.62,6001,2501601.52,3001,2001.22,3001,2000.72,2001,100 Hardened die steel JC8118 70 0.7 2,400 1,150 70 0.8 2,000 1,000 SKD61, DAC, DHA(1.2344, 1.2379)JC5118JC8015120 0.5 2,400 1,150 120 0.6 2,000 1,000 40-50HRC ※DH103 160 0.3 2,200 1,050 160 0.3 1,900 950 Grey & Nodularcast ironFC, FCD (GG, GGG)Below 300HBJC8015JC5118JC8118701201601.43,1001,550 701.13,1001,5501200.63,0001,4001601.52,6001,4001.22,6001,4000.72,5001,300 JC8050 70 0.5 1,200 600 70 0.5 1,000 500 Titanium alloy35-43HRCJC8015JC5118 120 0.4 1,200 600 120 0.4 1,000 500 JC8118 160 0.2 1,100 490 160 0.2 980 440 JC8015 70 0.5 620 190 70 0.5 510 160 Inconel35-43HRC JC5118JC8118 120 0.4 560 190 120 0.4 470 160 JC8050 160 0.2 520 190 160 0.2 440 160 70 2 8,600 4,800 70 2 7,200 4,300 Aluminium alloy50-110HB FZ05 120 1.7 8,600 4,800 120 1.7 7,200 4,300 160 1.2 7,000 4,900 160 1.2 5,800 4,300 ℓ: Overhung length, ap: Depth of cut, n: Spindle speed, Vf: Feed speed ※For over 50HRC, recommend to use JC8003 without chipbreaker ■NOTE 1) The cutting parameters to be adjusted according to the machine rigidity o rwork rigidity. 2) In case chatter occurrs, recommend to reduce depth of cut or feed speed. 3) If machine does not have enough power, recommend to reduce depth of cut first and reduce spindle speed and feed speed. 4 Use air blow to flush the chips out. 5) In case of 50-55HRC (Hardened die steel), recommend to reduce ap, n, Vf by 30% on above table. 6) In case of Titanium alloy or Inconel, recommended wet cutting. B115 ℓ : Overhung length

Общий каталог Dijet 2012 на русском

Общий каталог Dijet 2012 на русском