Общий каталог Dijet 2018 - страница 126

Навигация

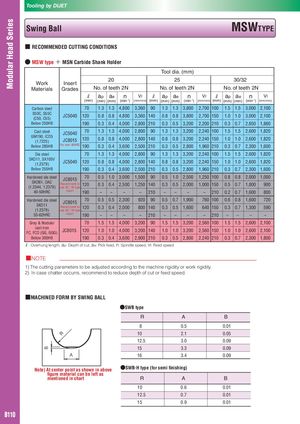

Tooling by DIJET Swing Ball MSWTYPE ■ RECOMMENDED CUTTING CONDITIONS ● MSW type + MSN Carbide Shank Holder Tool dia. (mm) Work Insert 20 25 30/32 Materials Grades No. of teeth 2N No. of teeth 2N No. of teeth 2N ℓ ap ae n Vf ℓ ap ae n Vf ℓ ap ae n Vf (mm) (mm) (mm) (min-1) (mm/min) (mm) (mm) (mm) (min-1) (mm/min) (mm) (mm) (mm) (min-1) (mm/min) Carbon steel 70 1.3 1.3 4,800 3,360 90 1.3 1.3 3,800 2,700 100 1.5 1.5 3,000 2,100 S50C, S55C(C50, C55)JC5040 120 0.8 0.8 4,800 3,360 140 0.8 0.8 3,800 2,700 150 1.0 1.0 3,000 2,100 Below 250HB 190 0.3 0.4 4,000 2,800 210 0.3 0.5 3,200 2,200 210 0.3 0.7 2,650 1,860 Cast steelGM190, ICD5(1.7225)JC5040 70 1.3 1.3 4,000 2,800 90 1.3 1.3 3,200 2,240 100 1.5 1.5 2,600 1,820JC80151200.80.84,0002,8001400.80.83,2002,2401501.01.02,6001,820 Below 285HB For over 40HRC 190 0.3 0.4 3,600 2,500 210 0.3 0.5 2,800 1,960 210 0.3 0.7 2,300 1,600 Die steel 70 1.3 1.3 4,000 2,800 90 1.3 1.3 3,200 2,240 100 1.5 1.5 2,600 1,820 SKD11, SX105V(1,2379)JC5040 120 0.8 0.8 4,000 2,800 140 0.8 0.8 3,200 2,240 150 1.0 1.0 2,600 1,820 Below 255HB 190 0.3 0.4 3,600 2,500 210 0.3 0.5 2,800 1,960 210 0.3 0.7 2,300 1,600 Hardened die steelSKD61, DAC(1.2344, 1.2379)JC801570Recommend touse−M○W type1200.51.03,0001,500900.51.02,500 1,250 100 0.8 0.8 2,000 1,0000.30.42,5001,2501400.30.52,0001,0001500.50.71,800900 40-50HRC insert 190 – – – – 210 – – – – 210 0.2 0.7 1,600 800 Hardened die steelSKD11(1.2379)JC8015 70Recommend touse−M○W type1200.50.52,3000.30.42,000920900.50.71,9008001400.30.51,600760100 0.6 0.8 1,600 7206401500.30.71,300590 55-62HRC insert 190 – – – – 210 – – – – 210 – – – – Grey & Nodular 70 1.5 1.5 4,000 3,200 90 1.5 1.5 3,200 2,560 100 1.5 1.5 2,600 2,100 cast ironFC, FCD (GG, GGG)JC8015 120 1.0 1.0 4,000 3,200 140 1.0 1.0 3,200 2,560 150 1.0 1.0 2,600 2,100 Below 300HB 190 0.3 0.4 3,600 2,900 210 0.3 0.5 2,800 2,240 210 0.3 0.7 2,300 1,800 ℓ: Overhung length, ap: Depth of cut, ae: Pick feed, n: Spindle speed, Vf: Feed speed ■NOTE 1) The cutting parameters to be adjusted according to the machine rigidity or work rigidity. 2) In case chatter occurrs, recommend to reduce depth of cut or feed speed. ■MACHINED FORM BY SWING BALL ●SWB type R A B 8 0.5 0.01 10 2.1 0.05 12.5 3.0 0.09 15 3.3 0.09 16 3.4 0.09 Note) At center point as shown in above ●SWB-H type (for semi finishing) figure material can be left as mentioned in chart R A B 10 0.6 0.01 12.5 0.7 0.01 15 0.9 0.01 B110

Общий каталог Dijet 2012 на русском

Общий каталог Dijet 2012 на русском