Общий каталог Dijet 2018 - страница 110

Навигация

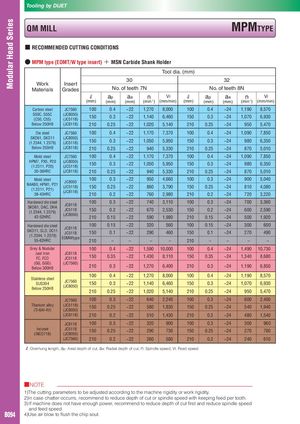

Tooling by DIJET QM MILL MPMTYPE ■ RECOMMENDED CUTTING CONDITIONS ● MPM type (EOMT/W type insert) + MSN Carbide Shank Holder Tool dia. (mm) 30 32 Work Insert Materials Grades No. of teeth 7N No. of teeth 8N ℓ ap ae n Vf ℓ ap ae n Vf (mm) (mm) (mm) (min-1) (mm/min) (mm) (mm) (mm) (min-1) (mm/min) Carbon steel JC7560 100 0.4 ~22 1,270 8,000 100 0.4 ~24 1,190 8,570 S50C, S55C(C50, C55)(JC8050)(JC5118)150 0.3 ~22 1,140 6,460 150 0.3 ~24 1,070 6,930 Below 250HB (JC8118) 210 0.25 ~22 1,020 5,140 210 0.25 ~24 950 5,470 Die steel JC7560 100 0.4 ~22 1,170 7,370 100 0.4 ~24 1,090 7,850 SKD61, SKD11 (JC8050)(1.2344, 1.2379)(JC5118)1500.3~221,050 5,950 150 0.3 ~24 980 6,350 Below 255HB (JC8118) 210 0.25 ~22 940 5,330 210 0.25 ~24 870 5,010 Mold steel JC7560 100 0.4 ~22 1,170 7,370 100 0.4 ~24 1,090 7,850 HPM7, PX5, P20 (JC8050)(1.2311, P20)(JC5118)1500.3~221,050 5,950 150 0.3 ~24 980 6,350 30-36HRC (JC8118) 210 0.25 ~22 940 5,330 210 0.25 ~24 870 5,010 Mold steelNAK80, HPM1, P21(1.2311, P21)38-43HRCJC8050(JC5118)(JC8118)1001502100.30.250.2~22~22~229504,6608603,7907602,9801000.3~241500.25~242100.2~249005,0408104,0807203,220 Hardened die steelSKD61, DAC, DHA(1.2344, 1.2379)42-52HRCJC8118JC5118(JC8050)1001502100.30.20.15~22~22~227403,1106702,5305901,9801000.3~241500.2~242100.15~247003,3606002,5905001,920 Hardened die steelSKD11, SLD, DC11(1.2344, 1.2379)55-62HRCJC8118JC5118EOMWtype1001502100.150.1–~22~22–320560290460––1000.15~241500.1~24210––300600270490–– Grey & Nodular 100 0.4 ~22 1,590 10,000 100 0.4 ~24 1,490 10,730 cast ironFC, FCD JC8118JC5118 150 0.35 ~22 1,430 8,110 150 0.35 ~24 1,340 8,680 (GG, GGG) (JC7560)Below 300HB2100.3 ~22 1,270 6,400 210 0.3 ~24 1,190 6,850 100 0.4 ~22 1,270 8,000 100 0.4 ~24 1,190 8,570 Stainless steelSUS304Below 250HBJC7560(JC8050)1502100.30.25~221,140 6,460~221,0205,140150 0.3 ~24 1,070 6,9302100.25~249505,470 JC7560 100 0.3 ~22 640 2,240 100 0.3 ~24 600 2,400 Titanium alloy (JC5118)(Ti-6Al-4V)(JC8050)1500.25~22 580 1,830 150 0.25 ~24 540 1,940 (JC8118) 210 0.2 ~22 510 1,430 210 0.2 ~24 480 1,540 JC8118 100 0.3 ~22 320 900 100 0.3 ~24 300 960 Inconel(INCO718) JC5118(JC8050)150 0.25 ~22 290 730 150 0.25 ~24 270 780 (JC7560) 210 0.2 ~22 260 580 210 0.2 ~24 240 610 ℓ:Overhung length, ap: Axial depth of cut, ae: Radial depth of cut, n: Spindle speed, Vf: Feed speed ■NOTE 1)The cutting parameters to be adjusted according to the machine rigidity or work rigidity. 2)In case chatter occurrs, recommend to reduce depth of cut or spindle speed with keeping feed per tooth. 3) If machine does not have enough power, recommend to reduce depth of cut first and reduce spindle speed and feed speed. B094 4)Use air blow to flush the chip sout.

Общий каталог Dijet 2012 на русском

Общий каталог Dijet 2012 на русском