Каталог Carmex общий 2021 - страница 405

Навигация

Каталог Carmex резьбофрезы из твёрдого сплава для обработки закалённых материалов HardCut

Каталог Carmex резьбофрезы из твёрдого сплава для обработки закалённых материалов HardCut Каталог Carmex корпуса резьбофрез для призматических пластин

Каталог Carmex корпуса резьбофрез для призматических пластин Каталог Carmex инструмент для вихревого нарезания резьбы

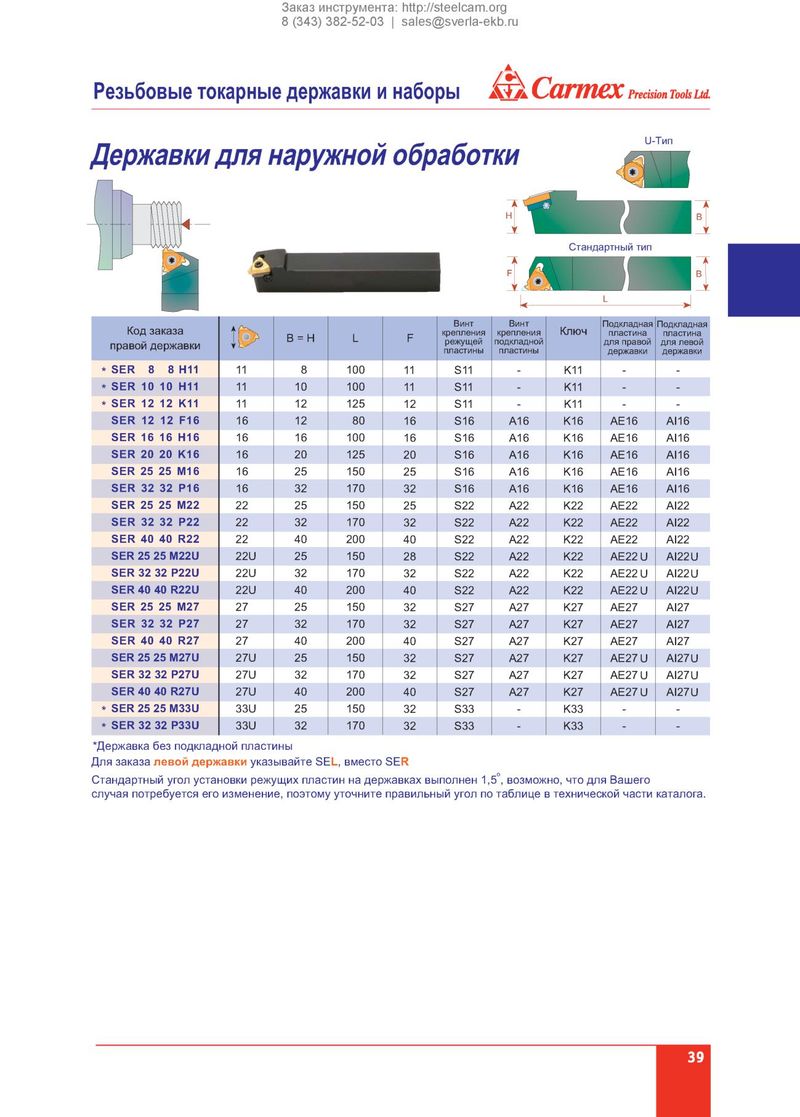

Каталог Carmex инструмент для вихревого нарезания резьбы Каталог Carmex державки для наружной обработки

Каталог Carmex державки для наружной обработки Каталог Carmex спиральные резьбофрезы со сменными пластинами

Каталог Carmex спиральные резьбофрезы со сменными пластинами

Ap = 2xD Ap max ® Supercut Solid Carbide Mills Ae ≤ 0.3xD Ae ≤ 0.1xD A B 7 fluted End-Mills Fz [mm/tooth] ISO Materials Class Vc[m/min] Cutting Diameter Ø10 Ø12 Ø16 Low & Medium Carbon Steels A:120-160 A:0.055 A:0.068 A:0.081 <0.55%C B:240-330 B:0.066 B:0.082 B:0.097 P High Carbon Steels ≥0.55%C A:120-160 A:0.055 A:0.068 A:0.081B:240-330B:0.066B:0.082B:0.097 Alloy Steels, Treated Steels A:100-140 A:0.055 A:0.068 A:0.081B:200-280B:0.066B:0.082B:0.097 Stainless Steel-Free Cutting A:80-140 A:0.050 A:0.068 A:0.074B:160-280B:0.060B:0.078B:0.089 M Stainless Steel-Austenitic A:70-130 A:0.050 A:0.068 A:0.074B:140-260B:0.060B:0.078B:0.089 Cast Steels A:70-130 A:0.050 A:0.068 A:0.074B:140-260B:0.060B:0.078B:0.089 Heat-resistant alloysSTitanium alloys A:20-40 A:0.048 A:0.056 A:0.064B:40-80B:0.058B:0.067B:0.077A:80-100A:0.048A:0.056A:0.064B:160-200B:0.058B:0.067B:0.077 Hardened Steel A:40-70 A:0.030 A:0.033 A:0.040 H <48 HRcHardened Steel B:80-140 B:0.036 B:0.040 B:0.048A:35-60A:0.022A:0.024A:0.030 48-58 HRc B:70-120 B:0.026 B:0.030 B:0.035 B14-15