Каталог Carmex общий 2021 - страница 383

Навигация

Каталог Carmex резьбофрезы из твёрдого сплава для обработки закалённых материалов HardCut

Каталог Carmex резьбофрезы из твёрдого сплава для обработки закалённых материалов HardCut Каталог Carmex корпуса резьбофрез для призматических пластин

Каталог Carmex корпуса резьбофрез для призматических пластин Каталог Carmex инструмент для вихревого нарезания резьбы

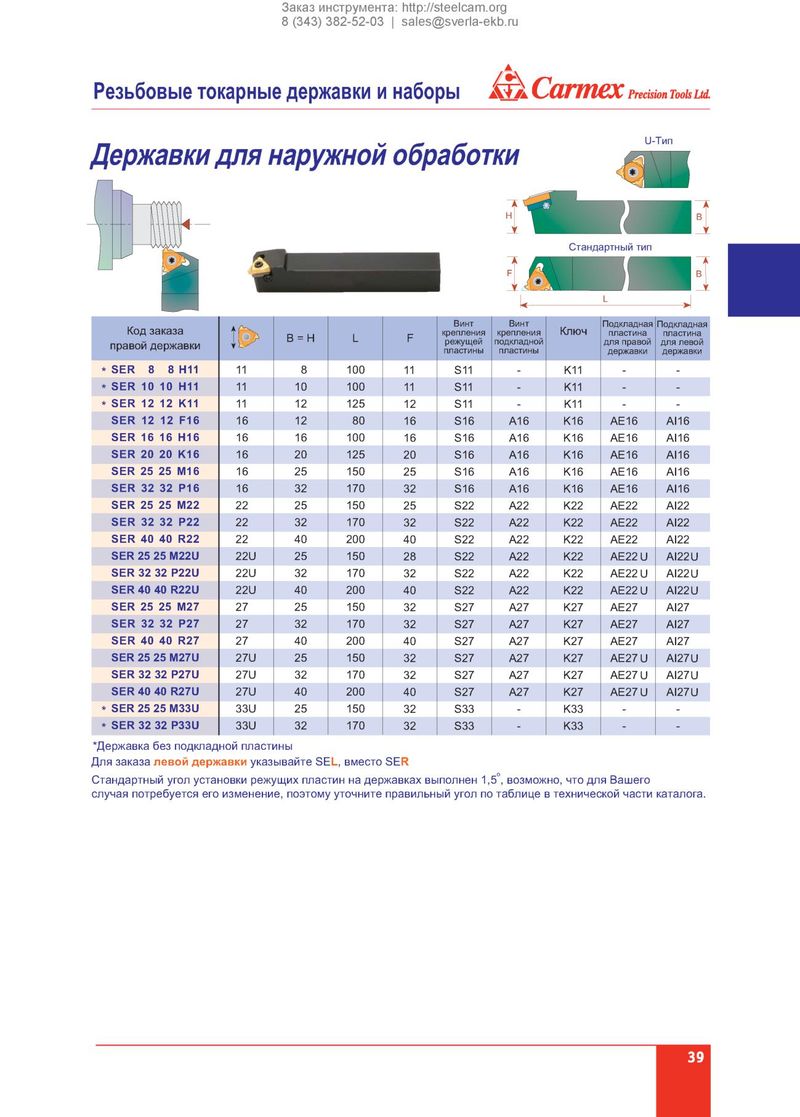

Каталог Carmex инструмент для вихревого нарезания резьбы Каталог Carmex державки для наружной обработки

Каталог Carmex державки для наружной обработки Каталог Carmex спиральные резьбофрезы со сменными пластинами

Каталог Carmex спиральные резьбофрезы со сменными пластинами

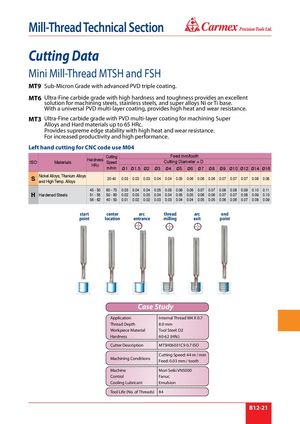

® Mill-Thread Technical Section Cutting Data Mini Mill-Thread MTSH and FSH MT9 Sub-Micron Grade with advanced PVD triple coating. MT6 Ultra-Fine carbide grade with high hardness and toughness provides an excellent solution for machining steels, stainless steels, and super alloys Ni or Ti base. With a universal PVD multi-layer coating, provides high heat and wear resistance. MT3 Ultra-Fine carbide grade with PVD multi-layer coating for machining Super Alloys and Hard materials up to 65 HRc. Provides supreme edge stability with high heat and wear resistance. For increased productivity and high performance. Left hand cutting for CNC code use M04 ISO Materials HardnessHRcCuttingSpeedm/minø1ø1.5ø2 Feed mm/toothCutting Diameter = Dø3ø4ø5ø6ø7ø8ø9ø10ø12ø14ø16 S Nickel Alloys, Titanium Alloysand High Temp. Alloys20-400.030.030.03 0.04 0.04 0.05 0.06 0.06 0.06 0.07 0.07 0.07 0.08 0.08 45 - 50 60 - 70 0.03 0.04 0.04 0.05 0.05 0.06 0.06 0.07 0.07 0.08 0.08 0.09 0.10 0.11 H Hardened Steels 51 - 55 50 - 60 0.02 0.03 0.03 0.04 0.04 0.05 0.05 0.06 0.06 0.07 0.07 0.08 0.09 0.10 56 - 62 40 - 50 0.01 0.02 0.02 0.03 0.03 0.04 0.04 0.05 0.05 0.06 0.06 0.07 0.08 0.09 start center arc thread arc end point location entrance milling exit point Case Study Application Internal Thread M4 X 0.7 Thread Depth 8.0 mm Workpiece Material Tool Steel: D2 Hardness 60-62 (HRc) Cutter Description MTSH06031C9 0.7 ISO Cutting Speed: 44 m / min Machining Conditions Feed: 0.03 mm / tooth Machine Mori Seiki VN5000 Control Fanuc Cooling Lubricant Emulsion Tool Life (No. of Threads) 84 B12-21