Каталог Carmex общий 2021 - страница 380

Навигация

Каталог Carmex резьбофрезы из твёрдого сплава для обработки закалённых материалов HardCut

Каталог Carmex резьбофрезы из твёрдого сплава для обработки закалённых материалов HardCut Каталог Carmex корпуса резьбофрез для призматических пластин

Каталог Carmex корпуса резьбофрез для призматических пластин Каталог Carmex инструмент для вихревого нарезания резьбы

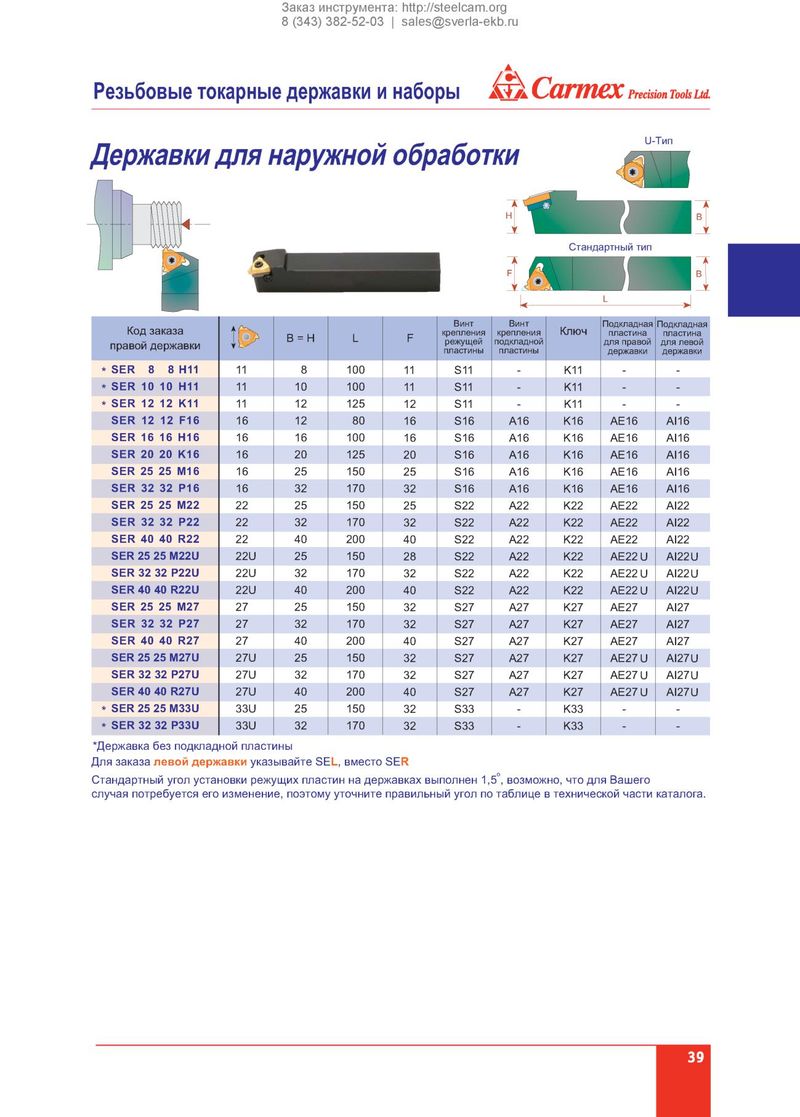

Каталог Carmex инструмент для вихревого нарезания резьбы Каталог Carmex державки для наружной обработки

Каталог Carmex державки для наружной обработки Каталог Carmex спиральные резьбофрезы со сменными пластинами

Каталог Carmex спиральные резьбофрезы со сменными пластинами

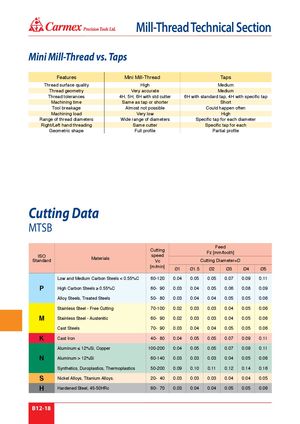

® Mill-Thread Technical Section Mini Mill-Thread vs. Taps Features Mini Mill-Thread Taps Thread surface quality High Medium Thread geometry Very accurate Medium Thread tolerances 4H, 5H, 6H with std cutter 6H with standard tap, 4H with specific tap Machining time Same as tap or shorter Short Tool breakage Almost not possible Could happen often Machining load Very low High Range of thread diameters Wide range of diameters Specific tap for each diameter Right/Left hand threading Same cutter Specific tap for each Geometric shape Full profile Partial profile Cutting Data MTSB ISOStandard Materials Cuttingspeed FeedFz [mm/tooth]VcCutting Diameter=D [m/min] Ø1 Ø1.5 Ø2 Ø3 Ø4 Ø5 Low and Medium Carbon Steels < 0.55%C 60-120 0.04 0.05 0.05 0.07 0.09 0.11 P High Carbon Steels ≥ 0.55%C 60- 90 0.03 0.04 0.05 0.06 0.08 0.09 Alloy Steels, Treated Steels 50- 80 0.03 0.04 0.04 0.05 0.05 0.06 Stainless Steel - Free Cutting 70-100 0.02 0.03 0.03 0.04 0.05 0.06 M Stainless Steel - Austenitic 60- 90 0.02 0.03 0.03 0.04 0.05 0.06 Cast Steels 70- 90 0.03 0.04 0.04 0.05 0.05 0.06 K Cast Iron 40- 80 0.04 0.05 0.05 0.07 0.09 0.11 Aluminum ≤ 12%Si, Copper 100-200 0.04 0.05 0.05 0.07 0.09 0.11 N Aluminum > 12%Si 60-140 0.03 0.03 0.03 0.04 0.05 0.06 Synthetics, Duroplastics, Thermoplastics 50-200 0.09 0.10 0.11 0.12 0.14 0.16 S Nickel Alloys, Titanium Alloys. 20- 40 0.03 0.03 0.03 0.04 0.04 0.05 H Hardened Steel, 45-50HRc 60- 70 0.03 0.04 0.04 0.05 0.05 0.06 B12-18