Каталог Carmex общий 2021 - страница 373

Навигация

Каталог Carmex резьбофрезы из твёрдого сплава для обработки закалённых материалов HardCut

Каталог Carmex резьбофрезы из твёрдого сплава для обработки закалённых материалов HardCut Каталог Carmex корпуса резьбофрез для призматических пластин

Каталог Carmex корпуса резьбофрез для призматических пластин Каталог Carmex инструмент для вихревого нарезания резьбы

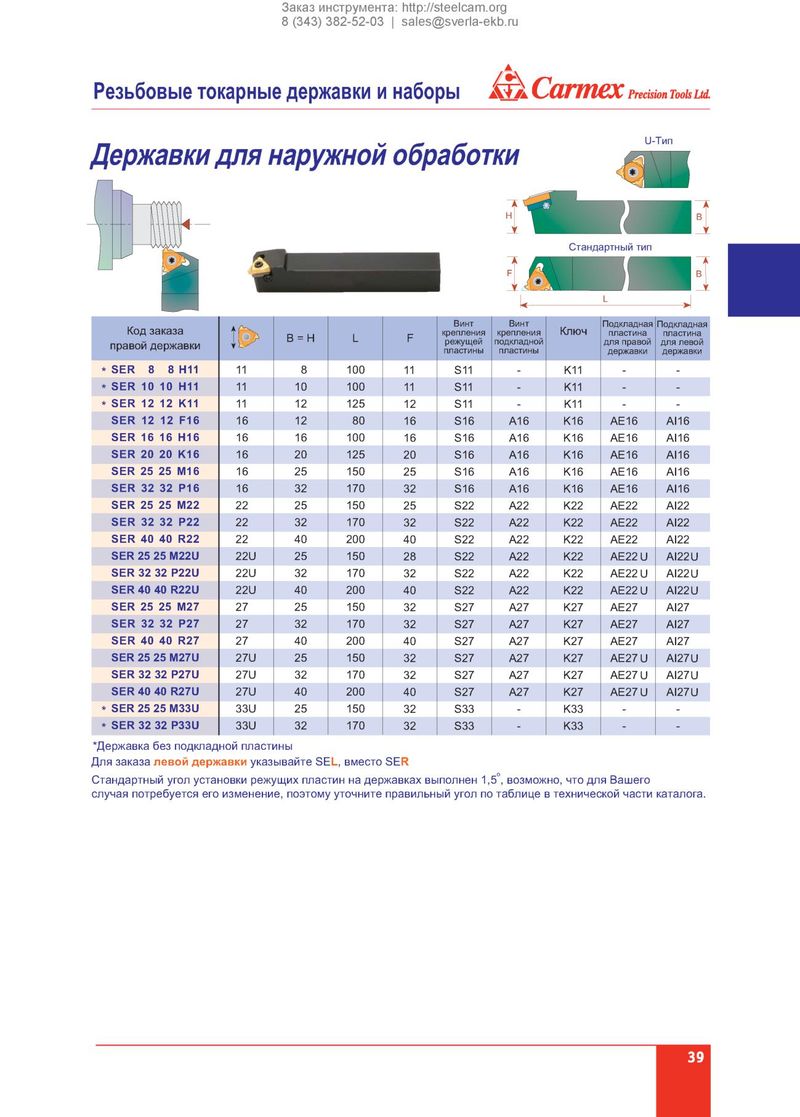

Каталог Carmex инструмент для вихревого нарезания резьбы Каталог Carmex державки для наружной обработки

Каталог Carmex державки для наружной обработки Каталог Carmex спиральные резьбофрезы со сменными пластинами

Каталог Carmex спиральные резьбофрезы со сменными пластинами

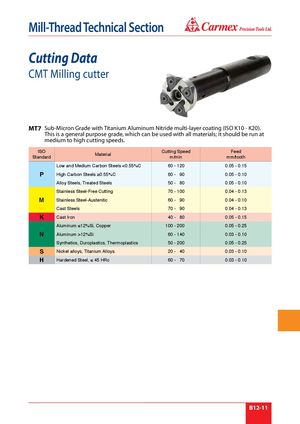

® Mill-Thread Technical Section Cutting Data CMT Milling cutter MT7 Sub-Micron Grade with Titanium Aluminum Nitride multi-layer coating (ISO K10 - K20). This is a general purpose grade, which can be used with all materials; it should be run at medium to high cutting speeds. ISOStandard Material Cutting Speed Feedm/minmm/tooth Low and Medium Carbon Steels <0.55%C 60 - 120 0.05 - 0.15 P High Carbon Steels ≥0.55%C 60 - 90 0.05 - 0.10 Alloy Steels, Treated Steels 50 - 80 0.05 - 0.10 Stainless Steel-Free Cutting 70 - 100 0.04 - 0.13 M Stainless Steel-Austenitic 60 - 90 0.04 - 0.10 Cast Steels 70 - 90 0.04 - 0.13 K Cast Iron 40 - 80 0.05 - 0.15 Aluminum ≤12%Si, Copper 100 - 200 0.05 - 0.25 N Aluminum >12%Si 60 - 140 0.03 - 0.10 Synthetics, Duroplastics, Thermoplastics 50 - 200 0.05 - 0.25 S Nickel alloys, Titanium Alloys. 20 - 40 0.03 - 0.10 H Hardened Steel, ≤ 45 HRc 60 - 70 0.03 - 0.10 B12-11