Каталог Carmex общий 2021 - страница 368

Навигация

Каталог Carmex резьбофрезы из твёрдого сплава для обработки закалённых материалов HardCut

Каталог Carmex резьбофрезы из твёрдого сплава для обработки закалённых материалов HardCut Каталог Carmex корпуса резьбофрез для призматических пластин

Каталог Carmex корпуса резьбофрез для призматических пластин Каталог Carmex инструмент для вихревого нарезания резьбы

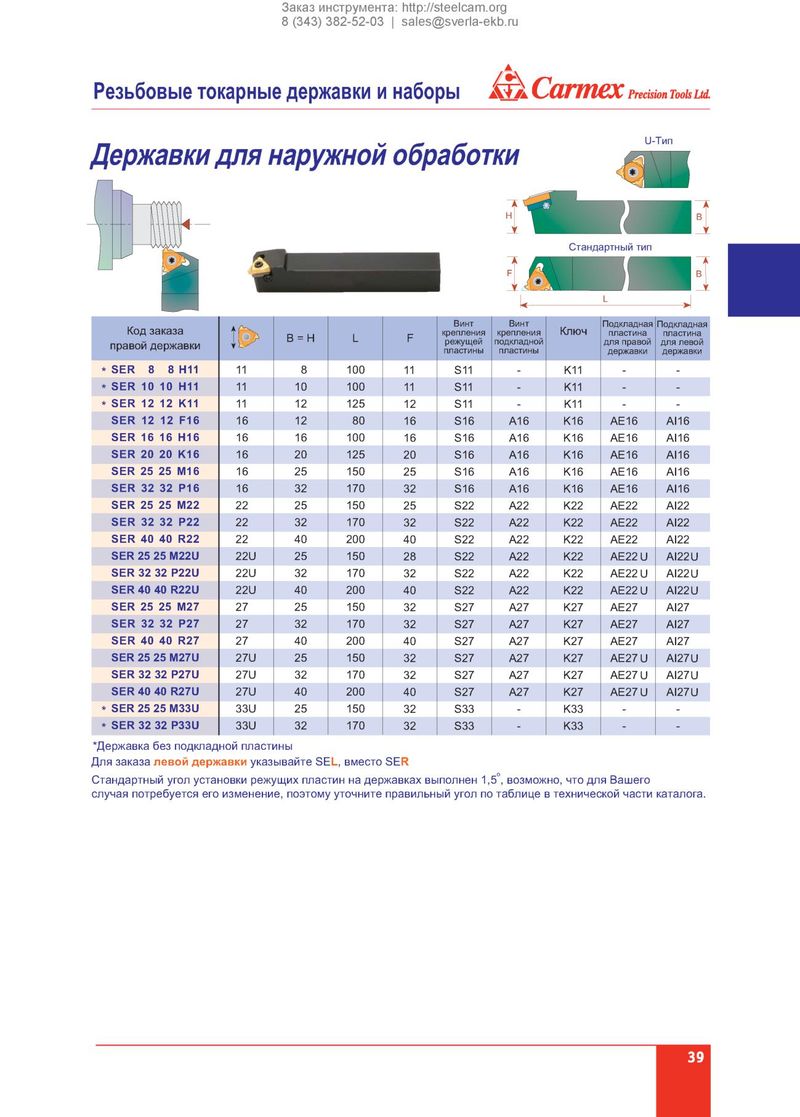

Каталог Carmex инструмент для вихревого нарезания резьбы Каталог Carmex державки для наружной обработки

Каталог Carmex державки для наружной обработки Каталог Carmex спиральные резьбофрезы со сменными пластинами

Каталог Carmex спиральные резьбофрезы со сменными пластинами

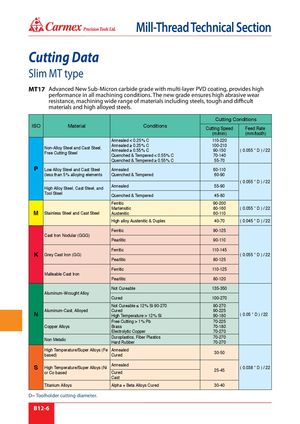

® Mill-Thread Technical Section Cutting Data Slim MT type MT17 Advanced New Sub-Micron carbide grade with multi-layer PVD coating, provides high performance in all machining conditions. The new grade ensures high abrasive wear resistance, machining wide range of materials including steels, tough and difficult materials and high alloyed steels. Cutting Conditions ISO Material Conditions Cutting Speed Feed Rate (m/min) (mm/tooth) Annealed < 0.25 % C 110-220 Non-Alloy Steel and Cast Steel,Free Cutting SteelAnnealed ≥ 0.25 % CAnnealed ≥ 0.55 % CQuenched & Tempered < 0.55 % C100-21090-150( 0.055 * D ) / 2270-140 Quenched & Tempered ≥ 0.55 % C 55-70 P Low Alloy Steel and Cast Steel Annealed 60-110 (less than 5 % alloying elements Quenched & Tempered 60-90 ( 0.055 * D ) / 22 High Alloy Steel, Cast Steel, and Annealed 55-90 Tool Steel Quenched & Tempered 45-80 Ferritic 90-200 Martensitic 80-160 ( 0.055 * D ) / 22 M Stainless Steel and Cast Steel Austenitic 60-110 High alloy Austenitic & Duplex 40-70 ( 0.045 * D ) / 22 Ferritic 90-125 Cast Iron Nodular (GGG) Pearlitic 90-110 Ferritic 110-145 K Grey Cast Iron (GG) ( 0.055 * D ) / 22 Pearlitic 80-125 Ferritic 110-125 Malleable Cast Iron Pearlitic 80-120 Not Cureable 135-350 Aluminum-Wrought Alloy Cured 100-270 Not Cureable ≤ 12 % Si 90-270 90-270 N Aluminum-Cast, Alloyed CuredHigh Temperature > 12% Si 90-22590-180 ( 0.05 * D ) / 22 Free Cutting > 1% Pb 70-225 Copper Alloys Brass 70-180 Electrolytic Copper 70-270 Non Metalic Duroplastics, Fiber PlasticsHard Rubber 70-27070-270 High Temperature/Super Alloys (Fe Annealedbased)Cured 30-50 S High Temperature/Super Alloys (Ni Annealedor Co basedCured 25-45 ( 0.038 * D ) / 22 Cast Titanium Alloys Alpha + Beta Alloys Cured 30-40 D= Toolholder cutting diameter. B12-6