Каталог Carmex общий 2021 - страница 327

Навигация

Каталог Carmex резьбофрезы из твёрдого сплава для обработки закалённых материалов HardCut

Каталог Carmex резьбофрезы из твёрдого сплава для обработки закалённых материалов HardCut Каталог Carmex корпуса резьбофрез для призматических пластин

Каталог Carmex корпуса резьбофрез для призматических пластин Каталог Carmex инструмент для вихревого нарезания резьбы

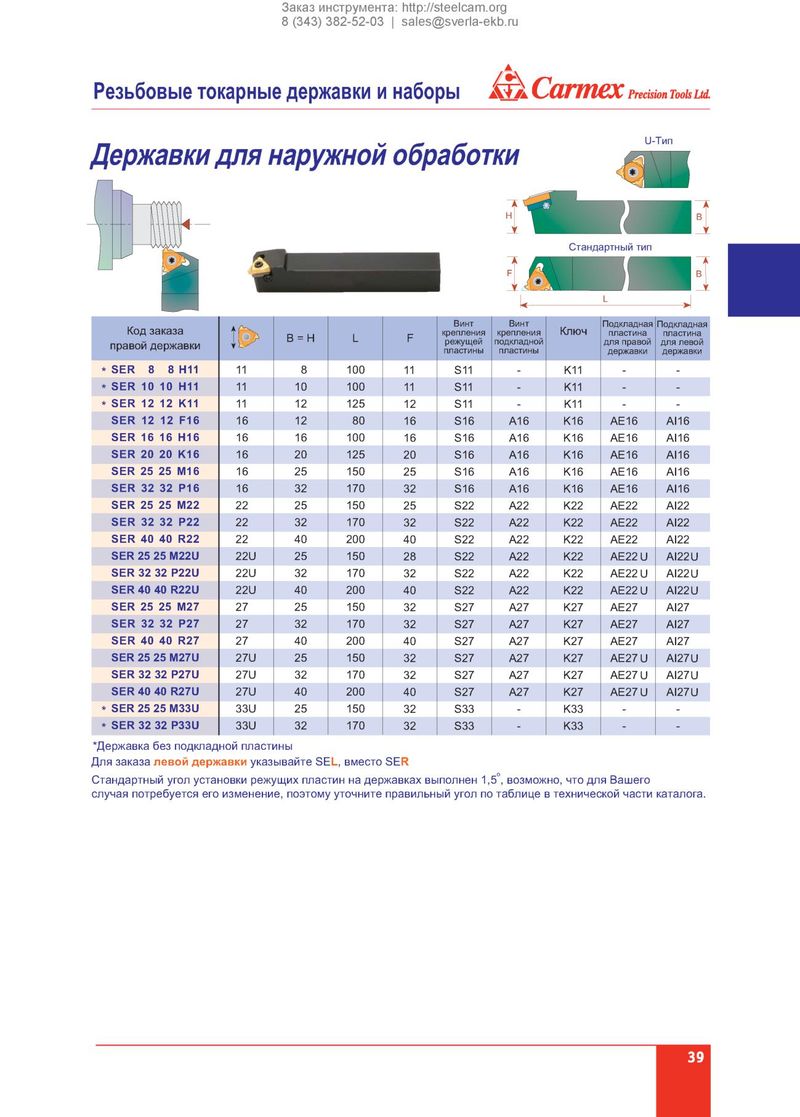

Каталог Carmex инструмент для вихревого нарезания резьбы Каталог Carmex державки для наружной обработки

Каталог Carmex державки для наружной обработки Каталог Carmex спиральные резьбофрезы со сменными пластинами

Каталог Carmex спиральные резьбофрезы со сменными пластинами

Mini Mill-ThMreaindi Mill-Thread® B09 MTS MTSB Threading from ISO M1 x 0.25 and 0-80UN. Solid carbide thread mills with internal coolant Working in high cutting speed. bore and increased number of flutes for high Short machining time. performance, shorter cycle time and improved Low cutting forces thanks to the short profile. tool life. No broken taps. Machining of hardened materials up to 45 HRc. MTI - For threading deep parts Advantages Enables machining in deep holes.Same tool can produce a wide range of threadsFMTI and pitches. Thread mills with a large number of flutes Same tool can produce both External and Internalthreads. that enables to achieve significant shortermachining time, increased productivity and highperformance. Coolant through the flutes is very effective for deep holes. Spiral flutes allow smooth cutting action. Shorter machining time due to multi (3 to 5) flutes. Longer tool life due to special triple coating. Contents: Page: Contents: Page: Product Identification 2 MTI 12-16 MTS 3-8 Partial Profile 60˚ 13 ISO 3-4 Partial Profile 60˚ with internal coolant 13 UN 5-6 Partial Profile 55˚ 14 G (55˚) BSW, BSP 7 ISO 15 MJ 8 UN 15 UNJ 8 Trapez-DIN 103 16 MTS Dental 9 Acme 16 ISO 9 FMTI Multi Flute 17 UN 9 ISO 17 MTSB 10-12 UN 17 ISO 11 UN 12 B09-1