Каталог Carmex общий 2021 - страница 151

Навигация

Каталог Carmex резьбофрезы из твёрдого сплава для обработки закалённых материалов HardCut

Каталог Carmex резьбофрезы из твёрдого сплава для обработки закалённых материалов HardCut Каталог Carmex корпуса резьбофрез для призматических пластин

Каталог Carmex корпуса резьбофрез для призматических пластин Каталог Carmex инструмент для вихревого нарезания резьбы

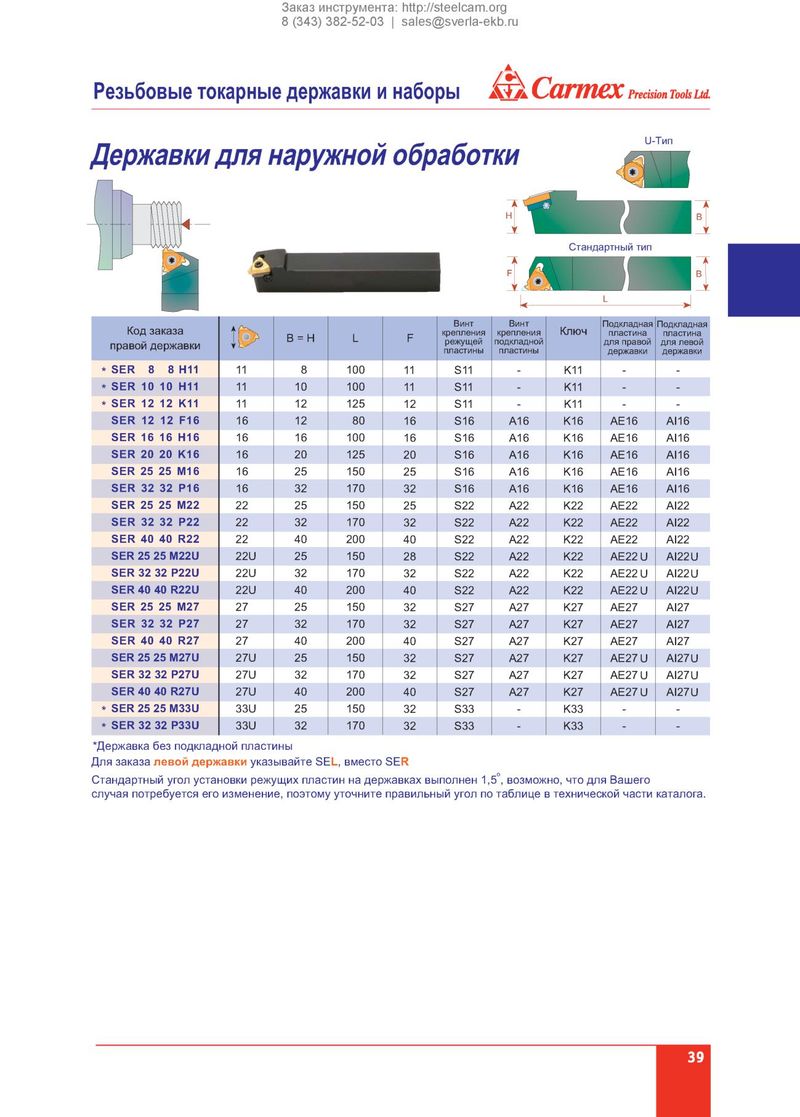

Каталог Carmex инструмент для вихревого нарезания резьбы Каталог Carmex державки для наружной обработки

Каталог Carmex державки для наружной обработки Каталог Carmex спиральные резьбофрезы со сменными пластинами

Каталог Carmex спиральные резьбофрезы со сменными пластинами

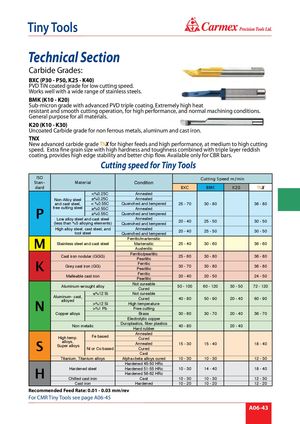

® Tiny Tools Technical Section Carbide Grades: BXC (P30 - P50, K25 - K40) PVD TiN coated grade for low cutting speed. Works well with a wide range of stainless steels. BMK (K10 - K20) Sub-micron grade with advanced PVD triple coating. Extremely high heat resistant and smooth cutting operation, for high performance, and normal machining conditions. General purpose for all materials. K20 (K10 - K30) Uncoated Carbide grade for non ferrous metals, aluminum and cast iron. TNX New advanced carbide grade TNX for higher feeds and high performance, at medium to high cutting speed. Extra fine grain size with high hardness and toughness combined with triple layer reddish coating, provides high edge stability and better chip flow. Available only for CBR bars. Cutting speed for Tiny Tools ISO Cutting Speed m/min Stan- Material Condition dard BXC BMK K20 TNX <%0.25C Annealed Non-Alloy steel ≥%0.25C Annealed and cast steel, < %0.55C Quenched and tempered 25 - 70 30 - 80 36 - 80 P free cutting steel ≥%0.55C≥%0.55CLow alloy steel and cast steelAnnealedQuenched and temperedAnnealed(less than %5 alloying elements)Quenched and tempered20 - 4025 - 5030 - 50 High alloy steel, cast steel, and Annealedtool steelQuenched and tempered20 - 4025 - 50 30 - 50 M Stainless steel and cast steel Ferritic/martensiticMartensiticAustenitic25 - 4030 - 60 36 - 60 Cast iron nodular (GGG) Ferritic/pearliticPearlitic 25 - 60 30 - 80 36 - 80 K Grey cast iron (GG) FerriticPearlitic 30 - 70 30 - 80 36 - 80 Malleable cast iron FerriticPearlitic 20 - 40 20 - 50 24 - 50 Aluminum-wrought alloy Not cureableCured 50 - 100 60 - 120 30 - 50 72 - 120 Aluminum- cast, ≤%12 SiNalloyed>%12 Si>%1 PbNot cureableCured 40 - 80 50 - 90 20 - 40 60 - 90High temperatureFree cutting Copper alloys Brass 30 - 60 30 - 70 20 - 40 36 - 70 Electrolytic copper Non metalic Duroplastics, fiber plasticsHard rubber40 - 80 20 - 40 High temp. Fe basedSalloys,Super alloysNi or Co basedAnnealedCuredAnnealedCured15 - 3015 - 40 18 - 40 Cast Titanium, Titanium alloys Alpha+beta alloys cured 10 - 30 10 - 30 12 - 30 Hardened 45-50 HRc H Hardened steelChilled cast iron Hardened 51-55 HRc 10 - 30 14 - 40Hardened 56-62 HRcCast10 - 3010 - 3018 - 4012 - 30 Cast iron Hardened 10 - 20 10 - 20 12 - 20 Recommended Feed Rate: 0.01 - 0.03 mm/rev For CMR Tiny Tools see page A06-45 A06-43