Каталог ZCC-CT фрезы монолитные - страница 44

Навигация

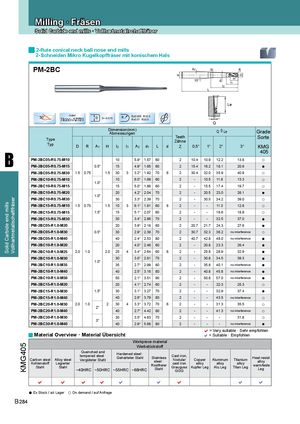

Solid Carbide end mills Vollhartmetallschaftfräser KMG405 d d1 A1 D < MGeinleliranl gTur·nFingrä/Asllgeenmeine Drehbearbeitung, ISO Kennzeichnung Solid Carbide end mills · Vollhartmetallschaftfräser 2-flute conical neck ball nose end mills 2- Schneiden Mikro Kugelkopffräser mit konischem Hals PM-2BC A2 R 10° Hl1 l2 L Le 30o CoatedNano-AITiN D 0~-0.015 R R±0.005 R>0.5R±0.01R≥0.5 Q Dimension(mm)Abmessungen Q = Le Grade Type Teeth SorteZähne Typ D R A1 H l2 l1 A2 d1 L d Z 0.5° 1° 2° 3° KMG B PM-2BC05-R0.75-M10PM-2BC05-R0.75-M15 405105.9°1.5760210.410.912.213.8○0.5o154.9°1.6560215.416.218.120.6● PM-2BC05-R0.75-M30 1.5 0.75 1.5 30 3 3.2° 1.92 70 6 2 30.4 32.0 35.9 40.9 ○ PM-2BC10-R0.75-M10 10 6.0° 1.69 601.0o 2 - 10.5 11.8 13.3 ○ PM-2BC10-R0.75-M15 15 5.0° 1.86 60 2 - 15.5 17.4 19.7 ○ PM-2BC10-R0.75-M20 20 4.2° 2.04 701.0o 2 - 20.5 23.0 26.1 ● PM-2BC10-R0.75-M30 30 3.3° 2.39 70 2 - 30.5 34.2 39.0 ○ PM-2BC15-R0.75-M10 1.5 0.75 1.5 10 3 6.1° 1.81 60 6 2 - - 11.3 12.8 ○ PM-2BC15-R0.75-M15 1.5o 15 5.1° 2.07 60 2 - - 16.6 18.9 ○ PM-2BC15-R0.75-M30 30 3.4° 2.86 70 2 - - 32.5 37.0 ● PM-2BC05-R1.0-M20 20 3.9° 2.18 60 2 20.7 21.7 24.3 27.6 ● PM-2BC05-R1.0-M30 0.5o 30 2.9° 2.36 70 2 30.7 32.3 36.2 no interference ○ PM-2BC05-R1.0-M40 40 2.4° 2.53 80 2 40.7 42.8 48.0 no interference ● PM-2BC10-R1.0-M20 20 4.0° 2.46 60 2 - 20.8 23.3 26.4 ● PM-2BC10-R1.0-M25 2.0 1.0 2.0 25 4 3.4° 2.64 60 6 2 - 25.8 28.9 32.9 ● PM-2BC10-R1.0-M30 30 3.0° 2.81 701.0o 2 - 30.8 34.5 39.3 ● PM-2BC10-R1.0-M35 35 2.7° 2.99 80 2 - 35.8 40.1 no interference ● PM-2BC10-R1.0-M40 40 2.5° 3.16 80 2 - 40.8 45.8 no interference ● PM-2BC10-R1.0-M50 50 2.1° 3.51 90 2 - 50.8 57.0 no interference ● PM-2BC15-R1.0-M20 20 4.1° 2.74 60 2 - - 22.3 25.3 ○ PM-2BC15-R1.0-M30 1.5o 30 3.1° 3.27 70 2 - - 32.9 37.4 ● PM-2BC15-R1.0-M40 40 2.6° 3.79 80 2 - - 43.5 no interference ○ PM-2BC20-R1.0-M30 2.0 1.0 2o 2 30 4 3.3° 3.72 70 6 2 - - 31.3 35.5 ○ PM-2BC20-R1.0-M40 40 2.7° 4.42 80 2 - - 41.3 no interference ○ PM-2BC30-R1.0-M30 30 3.5° 4.63 703o 2 - - - 31.8 ○ PM-2BC30-R1.0-M40 40 2.9° 5.68 80 2 - - - no interference ● = Very suitable · Sehr empfohlen Material Overview · Material Übersicht = Suitable · Empfohlen Workpiece material Werkstückstoff Carbon steelKohlenstoffStahlAlloy steelLegierterStahlQuenched andtempered steel ·Vergüteter StahlHardened steel ·Gehärteter StahlStainlesssteel ·Rostfreier~40HRC~50HRC~55HRC~68HRCStahlCast iron,NodularCopperAluminumcast ironalloyalloyGraugussKupfer LegAlu LegGGGTitaniumalloyTitan LegHeat resistalloywarmfesteLeg ● Ex Stock / ab Lager ○ On demand / auf Anfrage B 284

Каталог ZCC-CT оснастка

Каталог ZCC-CT оснастка Каталог ZCC-CT фрезы со сменными пластинами

Каталог ZCC-CT фрезы со сменными пластинами Каталог ZCC-CT сверла со сменными пластинами

Каталог ZCC-CT сверла со сменными пластинами Каталог ZCC-CT токарная обработка

Каталог ZCC-CT токарная обработка Каталог ZCC-CT сверла монолитные

Каталог ZCC-CT сверла монолитные