Общий каталог Yamawa 2021 - страница 720

Навигация

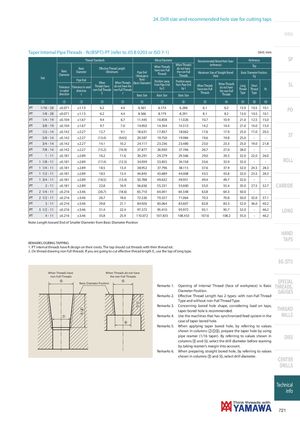

24. Drill size and recommended hole size for cutting taps Intro Taper Internal Pipe Threads - Rc(BSPT)-PT (refer to JIS B 0203 or ISO 7-1) Unit: mm Thread Standards Minor Diameter Recommended Bored Hole Sizes Reference SP Size BasicBasicDiameterDiameterEffective Thread Length(Minimum)Pipe End(WorkpieceWhen Threadshave non-FullThreadsWhen Threadsdo not havethe non-FullThreads(reference)Maximum Size of Straight BoredHoleTapBasic Diameter Position.ℓgPipe EndFace)WhenWhen Threads(Basic Diamater)ToleranceTolerance in axialThreads havedo not have thein radialdirectionnon-Full Threadsnon-Full ThreadsPosition awayfrom Pipe Endby ℓdirectioncℓtBasic SizeBasic SizePosition awayfrom Pipe Endby tBasic SizeWhen Threadshave non-FullThreadsWhen Threadsdo not havethe non-FullThreadsLongShortThreadThreadTypeTypeRcSL 1 2 3 4 5 6 7 8 9 0 ! " £ PT 1/16 - 28 ±0.071 ±1.13 6.2 4.4 6.561 6.174 6.286 6.1 6.2 13.0 10.5 10.1 PO PT 1/8 - 28 ±0.071 ±1.13 6.2 4.4 8.566 8.179 8.291 8.1 8.2 13.0 10.5 10.1 PT 1/4 - 19 ±0.104 ±1.67 9.4 6.7 11.445 10.858 11.026 10.7 10.9 21.0 12.5 15.0 PT 3/8 - 19 ±0.104 ±1.67 9.7 7.0 14.950 14.344 14.513 14.2 14.4 21.0 14.0 15.4 PT 1/2 - 14 ±0.142 ±2.27 12.7 9.1 18.631 17.837 18.062 17.6 17.9 25.0 17.0 20.5PT5/8 - 14±0.142±2.27(13.4)(9.65)20.58719.75019.98419.619.825.0--ST PT 3/4 - 14 ±0.142 ±2.27 14.1 10.2 24.117 23.236 23.480 23.0 23.3 25.0 19.0 21.8 PT 7/8 - 14 ±0.142 ±2.27 (15.2) (10.9) 27.877 26.930 27.196 26.7 27.0 28.0 - - PT 1 - 11 ±0.181 ±2.89 16.2 11.6 30.291 29.279 29.566 29.0 29.3 32.0 22.0 26.0 PT 1 1/8 - 11 ±0.181 ±2.89 (17.4) (12.5) 34.939 33.855 34.158 33.6 33.9 32.0 - - ROLL PT 1 1/4 - 11 ±0.181 ±2.89 18.5 13.4 38.952 37.796 38.115 37.6 37.9 32.0 24.5 28.3 PT 1 1/2 - 11 ±0.181 ±2.89 18.5 13.4 44.845 43.689 44.008 43.5 43.8 32.0 25.5 28.3 PT 1 3/4 - 11 ±0.181 ±2.89 (18.5) (13.4) 50.788 49.632 49.951 49.4 49.7 32.0 - - PT 2 - 11 ±0.181 ±2.89 22.8 16.9 56.656 55.231 55.600 55.0 55.4 35.0 27.5 32.7 CARBIDE PT 2 1/4 - 11 ±0.216 ±3.46 (26.7) (18.6) 65.710 64.041 64.548 63.8 64.3 50.0 - - PT 2 1/2 - 11 ±0.216 ±3.46 26.7 18.6 72.226 70.557 71.064 70.3 70.8 50.0 32.0 37.1 PT 3 - 11 ±0.216 ±3.46 29.8 21.1 84.926 83.064 83.607 82.8 83.3 52.0 36.0 40.2 PT 3 1/2 - 11 ±0.216 ±3.46 31.4 22.4 97.372 95.410 95.972 95.1 95.7 52.0 - 46.2 LONG PT 4 - 11 ±0.216 ±3.46 35.8 25.9 110.072 107.835 108.453 107.6 108.2 55.0 - 46.2 Note: Length toward End of Smaller Diameter from Basic Diameter Position HAND TAPS REMARKS DURING TAPPING 1. PT internal threads have R design on their crests. The tap should cut threads with their thread rot. 2. On thread drawing non-full threads. If you are going to cut effective thread length ℓ., use the tap of long type. EG (STI) When Threads have When Threads do not have non-Full Threads the non-Full Threads Basic Diameter Position SPECIALRemarks 1.OpeningofInternalThread(Faceofworkpiece)isBasicTHREADS, Diameter Position. GAUGES Remarks 2. Effective Thread Length has 2 types: with non-Full Thread Type and without non-Full Thread Type. Remarks 3. Concerning bored hole shape, considering load on taps,taper bored hole is recommended.THREAD Remarks 4. Use the machines that has synchronized feed system in the MILLS case of taper bored hole. Remarks 5. When applying taper bored hole, by referring to values shown in columns 258, prepare the taper hole by using pipe reamer (1/16 taper). By referring to values shown in DIES columns 9 and 0, select the drill diameter before reaming by taking reamer’s margin into account. Remarks 6. When preparing straight bored hole, by referring to values shown in columns 9 and 0, select drill diameter. CENTER DRILLS Technical info 721

Обший каталог Yamawa 2016 - 2017

Обший каталог Yamawa 2016 - 2017 Краткое руководство Yamawa по каталогам

Краткое руководство Yamawa по каталогам Общий каталог Yamawa 2022 - 2023

Общий каталог Yamawa 2022 - 2023 Каталоги Yamawa твердосплавные метчики для закаленной стали

Каталоги Yamawa твердосплавные метчики для закаленной стали