Общий каталог Yamawa 2021 - страница 703

Навигация

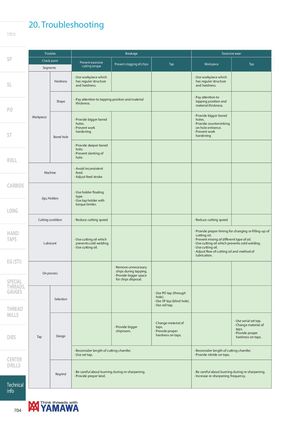

20. Troubleshooting Intro Troubles Breakage Excessive wear SP Check pointSegments Prevent excessivecutting torquePrevent clogging of chips Tap Workpiece Tap ∙ Use workpiece which ∙ Use workpiece which SL Hardness has regular structureand hardness. has regular structureand hardness. Shape ∙ Pay attention to tapping position and materialthickness. ∙ Pay attention totapping position andmaterial thickness. PO Workpiece ∙ Provide bigger bored ∙ Provide bigger bored holes. holes. ∙ Provide countersinking ∙ Prevent work on hole entrance. hardening. ∙ Prevent work ST Bored hole hardening ∙ Provide deeper bored hole. ∙ Prevent slanting of ROLL hole. ∙ Avoid inconsistent Machine feed. ∙ Adjust feed stroke CARBIDE ∙ Use holder floating Jigs, Holders type.∙ Use tap holder with torque limiter. LONG Cutting condition ∙ Reduce cutting speed ∙ Reduce cutting speed HAND ∙ Provide proper timing for changing or filling-up ofcutting oil. TAPS ∙ Use cutting oil which ∙ Prevent mixing of different type of oil. Lubricant prevents cold welding. ∙ Use cutting oil which prevents cold welding. ∙ Use cutting oil. ∙ Use cutting oil. ∙ Adjust flow of cutting oil and method of lubrication. EG (STI) ∙ Remove unnecessary On process chips during tapping.∙ Provide bigger space SPECIAL for chips disposal. THREADS, GAUGES ∙ Use PO tap (through Selection hole).∙ Use SP tap (blind hole). ∙ Use roll tap. THREAD MILLS ∙ Change material of∙ Provide biggertaps.chiproom.∙ Provide properDIESTapDesignhardness on taps.∙ Use serial set tap.∙ Change material oftaps.∙ Provide properhardness on taps. ∙ Reconsider length of cutting chamfer. ∙ Reconsider length of cutting chamfer. ∙ Use set tap. ∙ Provide nitride on taps. CENTER DRILLS Regrind ∙ Be careful about burning during re-sharpening.∙ Provide proper land. ∙ Be careful about burning during re-sharpening.∙ Increase re-sharpening frequency. Technical info 704

Обший каталог Yamawa 2016 - 2017

Обший каталог Yamawa 2016 - 2017 Краткое руководство Yamawa по каталогам

Краткое руководство Yamawa по каталогам Общий каталог Yamawa 2022 - 2023

Общий каталог Yamawa 2022 - 2023 Каталоги Yamawa твердосплавные метчики для закаленной стали

Каталоги Yamawa твердосплавные метчики для закаленной стали